Removing

Disconnect battery.

Remove the air intake sleeve, air filter housing (in vehicles with diesel engines and some gasoline) and battery.

In vehicles with 6-cyl. petrol engine, the battery is located in the luggage compartment; accordingly, it is required to remove the air filter housing with the bracket. Additionally, remove and set aside the crank module with holder.

Remove the battery holder frame.

Put a sufficient amount of rags that do not leave fibers in the area of the engine and gearbox.

Draw off the maximum amount of brake fluid using a filling and bleeding device or a device from the brake fluid reservoir.

For vehicles with manual transmission

Clamp the hose to the clutch release master cylinder with a clamp up to 25 mm.

Remove hose B from clutch master cylinder.

Continuation of assembly operations for all vehicles

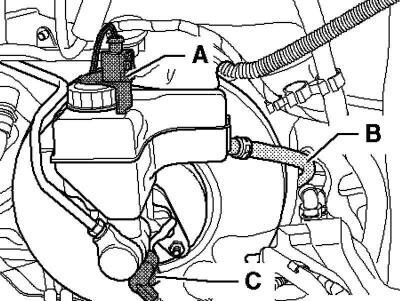

Pic. 6.46. Plug connection and hose for clutch release master cylinder

Remove connector A from float warning indicator sensor (pic. 6.46).

Remove connector C from brake light switch F.

Note: Vehicles with HBV (hydraulic brakes with vacuum booster) Disconnect the plug connection from the brake booster low pressure sensor.

Remove the vacuum hose from the brake booster.

For vehicles with manual transmission

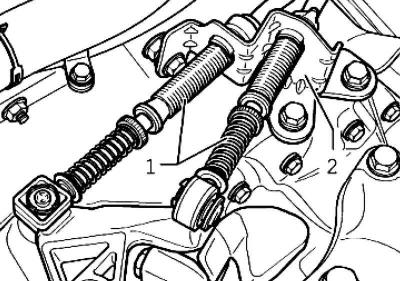

Pic. 6.48. Rope drives and counter support

Unscrew cable drives 1, unscrew counter support 2 and set aside (pic. 6.48).

For vehicles with 2-litre TDI engine

Remove the charge air pipe and extend as far as possible in front of the gearbox.

For vehicles with automatic transmission

Open the cable duct and remove the Servotronic harness, remove the cable duct from the console and set it aside.

Pry off the selector lever cable, remove it from the counterholder and holder, set aside

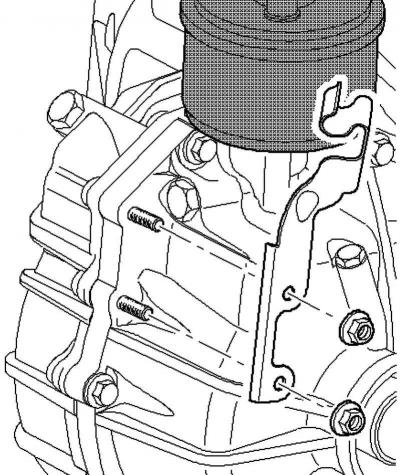

Pic. 6.49. Gear selector cable holder

Remove the selector lever cable holder (pic. 6.49).

Vehicles with 2 liter engine 110 kW FSI

Remove the EGR connecting pipe and coolant hose retainer from the cylinder head.

Continuation of assembly operations for all vehicles

Unscrew the brake pipes on the master brake cylinder, close the brake pipes with plugs from the repair kit 1H0 698 311 A.

In vehicles with 6-cyl. gasoline engine

Loosen the master cylinder nuts.

Carefully remove the brake master cylinder from the brake booster and also remove the heat shield.

Remove the brake booster vacuum sensor.

Continued job description for all vehicles

Loosen the nuts and remove the driver's footwell trim.

Disconnect the brake pedal from the brake booster.

Turn off nuts of 1 amplifier of brakes.

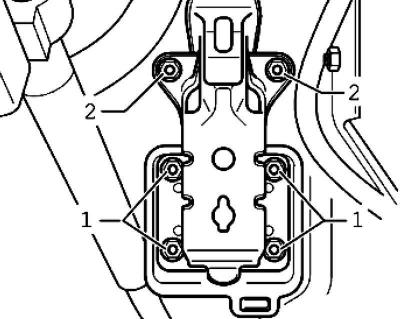

Pic. 6.50. Nuts of fastening of the amplifier of brakes and a basic arm

Loosen the two top nuts 2 of the support bracket (pic. 6.50).

Remove the brake booster from the vehicle.

Loosen the master cylinder nuts.

Carefully remove the master cylinder from the brake booster.

Installation

Installation is carried out in the reverse order.

When installing, consider the following factors.

Connect the brake pedal to the brake booster.

After installation, bleed the brake system and clutch.

Tightening torques

Brake booster to pedal assembly / transverse bulkhead: 25 Nm.

The main brake cylinder to the brake booster: 25 Nm.

Brake pipelines to the main brake cylinder: 8.5 mm - 17 Nm, 6 mm - 14 Nm.

Visitor comments