Attention: When disconnecting and connecting the battery, be sure to follow the sequence of actions described in the repair manual.

Attention: Some tools have a safety loop, which after using the tool should be put on the working part of the tool in order to protect the tool from damage and the worker from injury.

For any repairs, observe the valid instructions of the respective repair manuals.

Follow the regulations in force in your country.

Disconnect the ground wire from the battery before working on electrical equipment.

Unscrewing the ground wire from the battery (interruption of current in a circuit), to secure work on electrical equipment. Unscrew the positive terminal only to remove the battery.

Before starting repairs, the cause of the damage must first be eliminated, such as body parts with sharp edges, a faulty electrical consumer, corrosion.

When repairing the wiring of the on-board network, it is prohibited to carry out welding work.

Repairs to the onboard wiring and plugs may only be carried out using a cable repair kit.

When repairing cables, use only yellow wires.

Repaired wire points must not be wrapped again in standard automotive electrical tape, these places must be marked with yellow electrical tape.

Yellow wires and places marked with yellow electrical tape indicate that repairs were previously carried out here.

Crimp sleeves must not be repaired. If possible, run a new wire parallel to the damaged one.

After crimping, the crimp sleeve must be seated to prevent moisture from entering it.

Be sure to follow the additional instructions for repairing wiring in airbag and seat belt pretensioner systems, light cables, CAN bus wires, antenna cables and wires up to 0.35 mm2.

After each repair, it is necessary to test the operation of the repaired element. If necessary, read out the fault memories, clear them and/or reset the systems.

If possible, do not unscrew the ground wires from the body (risk of corrosion).

Repair of wires in airbag and seat belt pretensioner systems

In addition to general wiring repairs, when repairing wiring in airbag and seat belt pretensioner systems, the following guidelines must be observed

Caution: The airbag and seat belt pretensioner system may be damaged.

Caution: Failure to repair pretensioner and airbag harnesses may result in the failure of these restraint systems.

Attention: When repairing the wires of the airbags and seat belt tensioners, use only the contacts, plugs and wires intended for this purpose.

Note: Airbag and belt tensioner wires may only be repaired with a cable repair kit.

Note: Follow the instructions on the stickers on the parts of the car regarding high voltage parts. Residual pressure must be relieved during repair work.

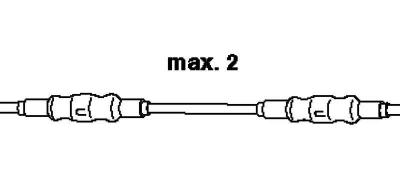

Pic. 7.124. Air bag wire

The airbag or seat belt pretensioner wire may be repaired in no more than two places (pic. 7.124).

Repaired areas increase electrical resistance, and thus may cause malfunctions in the system self-diagnosis.

When repairing the harnesses of the air bag module and the seat belt pretensioner, the crimp connectors must always be seated to prevent corrosion.

When repairing cables, use only yellow wires.

Do not wrap the repaired area with standard electrical tape, it should be marked by wrapping it with yellow electrical tape.

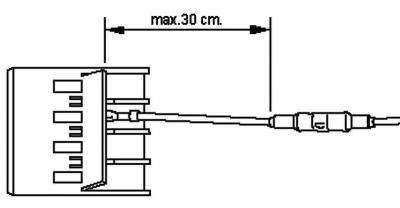

Pic. 7.125. Distance from connector housing

The repaired area in the area of the airbag and seat belt pretensioner must be no more than 30 cm from the next connector housing (pic. 7.125).

Together with the yellow tape marking, this provides an easy overview of the repair work carried out.

Wires for squibs (airbags) in mass production they are twisted with a pitch of 20 mm±5. Such a twist pitch is indicated in serial production by standard part numbers for pairs of wires, therefore, when repairing, be sure to observe the pitch of twisted wires.

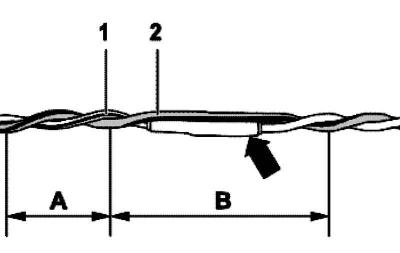

Pic. 7.126. Twisting pitch

When repairing wires to squibs (airbags) must be the same length. When twisting wires 1 and 2, the twisting pitch A=20 mm± (pic. 7.126).

In this case, a piece of wire must not form, for example, in the area of welded contacts longer than B = 100 mm without twisting the wires.

Visitor comments