Other jacks must not be used. The car may fall off the jack.

Never start the engine with the vehicle raised.

If it is necessary to work under the vehicle, the vehicle must be securely positioned on suitable pitches.

If one of the wheels fails, the car should be parked as far away from the traffic flow as possible.

Apply the parking brake securely. Engage a gear or put the selector in position «R», and place a stone or other object under the opposite wheel to prevent the vehicle from rolling.

If you have a trailer, you must first disconnect the trailer from the vehicle.

Remove the on-board tool kit and spare wheel from the vehicle.

Depending on the wheel design, remove one of the caps listed below, which is installed on the wheel:

Pic. 1.85. Removing the decorative cap

Remove the full size wheel cover using a wire puller and a wheel wrench. Hook the puller into one of the holes in the cap, insert the wheel wrench through the puller and pull the cap off (pic. 1.85).

Pic. 1.86. Removing the center cap

Remove the central cap using a wire stripper - see Figure 1.86.

Pic. 1.87. Removing wheel bolt caps

Remove the wheel bolt caps - see Figure 1.87.

Slide the wheel wrench as shown in the figure until it stops on the head of the wheel bolt and turn the wrench counterclockwise. In this case, you should press your hand on the knob of the key as close as possible to its end.

If the wheel bolts do not loosen, you can, as a last resort, carefully press the wheel wrench with your foot. At the same time, you should try not to lose your balance; you can lean on the body of the car for emphasis.

The wheel bolts will loosen after one turn.

Attention: If there are discs with a screwed outer ring, the special disc bolts must not be loosened under any circumstances. The discs will be significantly weakened - risk of accident.

Vehicle jacking points

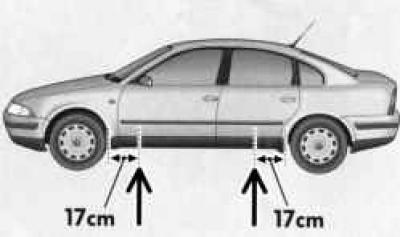

Pic. 1.88. Supporting places for a jack

Figure 1.88 shows reference points (see arrows), under the middle of which a jack should be installed. On some car models, these places are marked with special markings.

Attention: If the jack is not installed under the place marked on the vehicle or indicated here, damage to the vehicle's bodywork may occur. In addition, there is a risk of injury.

Attention: When installing the jack on soft ground, the vehicle may fall off the jack.

Therefore, in this case, it is necessary to put the jack on a hard surface. If necessary, a stable and relatively large support should be used.

For slippery surfaces (e.g. ceramic tiles) non-slip pad should be used (e.g. rubber band).

The place under the jack in front is closed with a lid, which should be folded up.

Pic. 1.89. Installing a car jack

Place a jack under the car (pic. 1.89).

- The jack must rest on the ground with its entire supporting surface.

- Align the position of the jack and at the same time raise the leg of the jack until it fits snugly against the vertical rib.

Attention: The paw of a jack should densely grasp a vertical edge of a spar so that when lifting the car the jack could not tip over - see, drawing 1.89.

Loosening wheel bolts

Pic. 1.90. Removing wheel bolts

Raise the vehicle until the defective wheel is about an inch off the ground.

Using the hexagon in the handle of the screwdriver, unscrew the loose wheel bolts, lay them on a clean surface (wheel cap, piece of cloth, sheet of paper) next to the jack and remove the wheel.

Put on the spare wheel and use the hexagon in the screwdriver handle to lightly tighten all wheel bolts.

Take a screwdriver and tighten the wheel bolts by hand.

To prevent rust, you can lightly lubricate the rim in the area of contact with the hub.

In this case, the grease must not get into the threaded holes of the hub.

Wheel bolts must be clean and easy to screw in; Under no circumstances should they be lubricated with oil or any kind of grease.

Lower the vehicle and tighten the wheel bolts crosswise using the wheel wrench.

On a vehicle with a full-size spare tire, put the wheel covers back on.

When installing a full-size hubcap, you must first push the cap in at the location of the tire valve and then lock the cap around the entire circumference.

Pic. 1.91. Installation of the central hood

On vehicles with alloy wheels, the center wheel cap may have a certain protrusion. Make sure that this protrusion falls into the recess intended for it - see arrow (pic. 1.91).

Place the replaced wheel in the spare wheel well and securely fasten it.

Instructions for changing a wheel

The internal hexagon in the screwdriver handle makes it easier to tighten the wheel bolts. In this case, the working body of the screwdriver must be removed.

Never use a socket head screwdriver to loosen or tighten the wheel bolts.

After changing a wheel, do the following:

- immediately check the air pressure in the installed spare wheel;

- at the first opportunity, check the tightening torque of the wheel bolts with a torque wrench: The tightening torque of the wheel bolts is 120 Nm.

If, when changing a wheel, it is found that the wheel bolts are corroded and are tight in and out, they should be replaced before checking the tightening torque.

Until this is done, one should move carefully and at a moderate speed.

A defective wheel should be repaired as soon as possible.

Wheel bolts

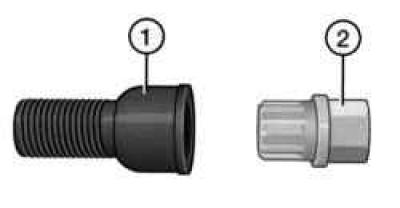

Pic. 1.92. Security bolt: 1 - wheel bolt; 2 - adapter for wheel bolt

Loose or tightened wheel bolt.

Insert adapter 2 into wheel bolt 1 as far as it will go.

Slide the wheel wrench from the on-board tool kit as far as it will go onto adapter 2. You can now loosen or tighten the wheel bolt.

After changing a wheel, pull the adapter out of the wheel bolt.

On the end of the adapter, the number of the secret code is stamped.

You should write down this code number and keep it carefully. Only on the basis of the code number can a spare adapter be ordered from a Volkswagen workshop.

Visitor comments