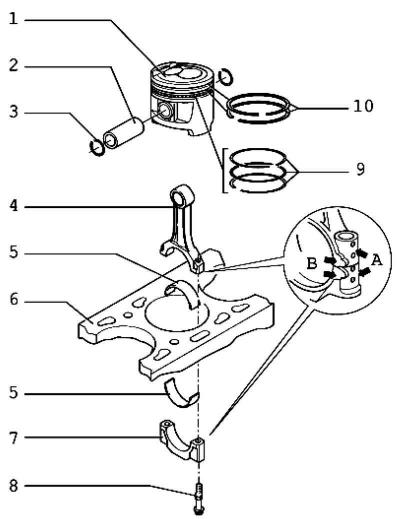

Pic. 2.27. Connecting rod and piston group: 1 - piston; 2 - piston pin; 3 - retaining ring; 4 - connecting rod; 5 - bearing shell; 6 – block of cylinders; 7 - connecting rod cover; 8 – a bolt of fastening of a cover of a rod; 9 - oil scraper rings; 10 - compression rings

Note: All bearing and working surfaces must be lubricated with engine oil before installation work.

Piston check

Measure about 12 mm from the bottom edge, at right angles to the piston pin axis. The maximum allowable deviation from the nominal size is 0.04 mm.

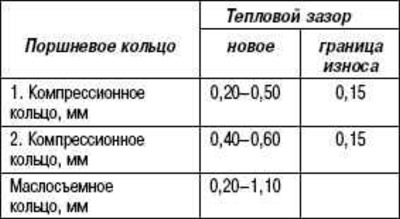

Checking the thermal clearance of the piston rings

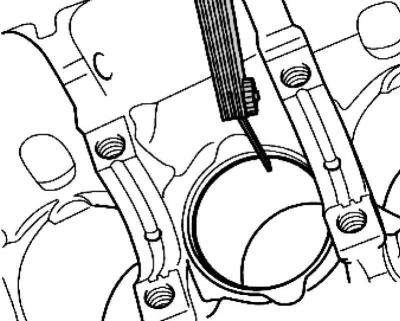

Pic. 2.28. Checking the thermal clearance of the piston rings

Drive the ring from above at a right angle to the lower hole of the cylinder, at a distance of about 15 mm from its edge (pic. 2.28).

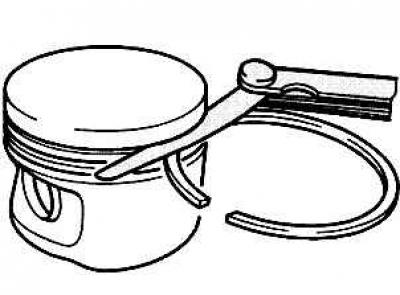

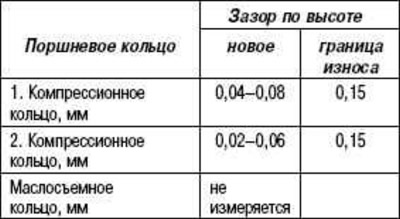

Checking the clearance of piston rings in height

Pic. 2.29. Checking the clearance of piston rings in height

Before checking, clean the annular groove (pic. 2.29).

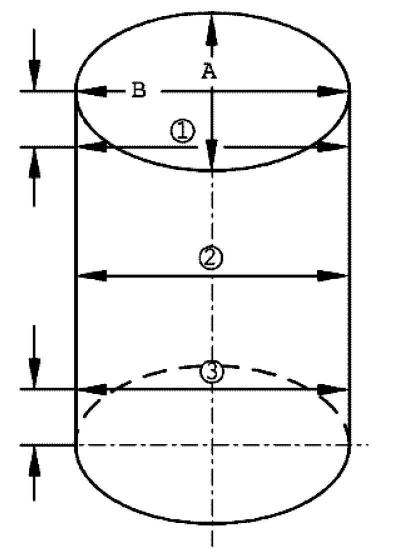

Checking the cylinder diameter

Pic. 2.30. Cylinder Diameter Test Diagram

Take measurements criss-cross at three locations in transverse direction B and longitudinal direction B (pic. 2.30). The maximum allowable deviation from the nominal size is 0.08 mm.

Note: It is forbidden to measure cylinder diameters when the cylinder block is fixed to the engine and gearbox retainer, otherwise incorrect results may be obtained.

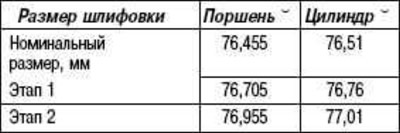

Piston and cylinder dimensions

Visitor comments