Removing

Note: During further operations, the ground wire must be disconnected from the battery. Therefore, you must first check whether a radio with coding is installed in the car.

Note: The engine is removed with the gearbox down.

Note: After installing the engine, it is necessary to reinstall in the same places all cable ties removed or cut when dismantling it.

Attention: For any assembly work, in particular in the engine compartment due to the tight layout, the following must be observed.

Attention: Highways of all types (e.g. fuel, hydraulic, activated charcoal absorber, cooling systems, air conditioning circuits, brake lines, vacuum hoses), as well as electrical wires must be laid as they were originally laid.

Caution: To avoid damage, ensure sufficient clearance to all moving and hot parts.

Disconnect the ground wire from the battery with the ignition off.

Pic. 2.82. engine cover

Remove the engine cover, if applicable (pic. 2.82).

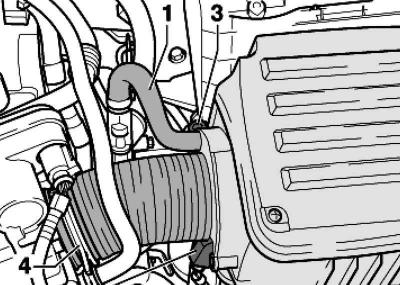

Disconnect hose 1 and connector from intake air temperature sensor 2 on air filter housing.

Pic. 2.83. Air filter housing with air hose

Unscrew the bolt 3 and remove the air filter housing with the air hose 4 (pic. 2.83).

Remove the battery and battery holder frame.

Remove the wiper arms, plenum box cover and plenum box on the front wall.

Disconnect the engine wiring harness connector at the engine control unit.

Remove the wiper arms and plenum box cover.

Disconnect the engine wiring harness connector at the engine control unit.

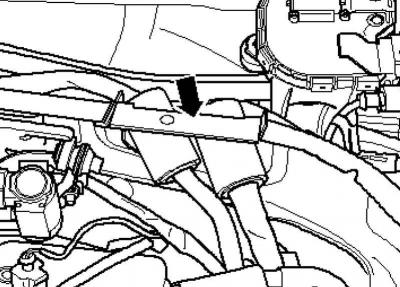

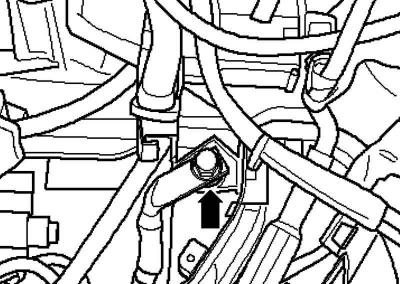

Pic. 2.84. Entry holder for engine wiring harness

Unlock the entry for the engine wiring harness and pull up (pic. 2.84).

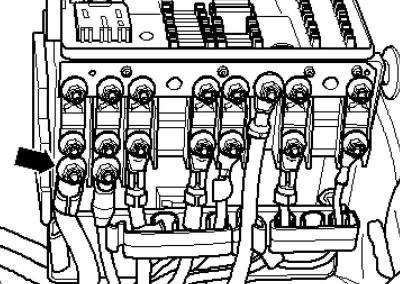

Pic. 2.85. Fastening the generator cable to the fuse box

Unscrew the generator cable from the fuse block (pic. 2.85).

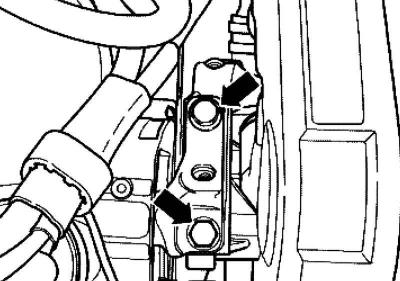

Pic. 2.86. Earth cable fastening

Unscrew the ground cable from the side member (pic. 2.86).

Open the cable clamps on the side member.

Disconnect the engine wiring harness connectors from the body and place the wiring harness on the engine.

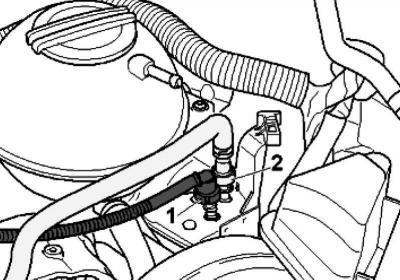

Pic. 2.87. Pipeline and fuel line

Separate the ventilation line 1 and the fuel line 2. To do this, press the latches (pic. 2.87).

Remove the noise screen.

Bring the radiator frame to the service position.

Drain coolant.

Remove the front left fender liner.

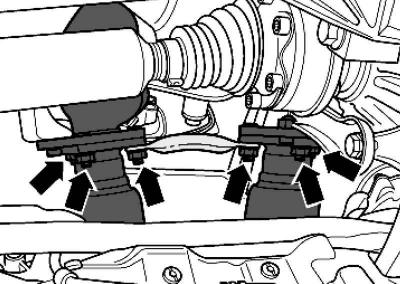

Pic. 2.88. Exhaust holder

Unscrew the exhaust system holder (pic. 2.88).

Note: On vehicles with engine codes BLX and BVX, the exhaust system bracket is removed together with the cable duct for the lambda probes behind the catalytic converter.

Front wheel drive vehicles

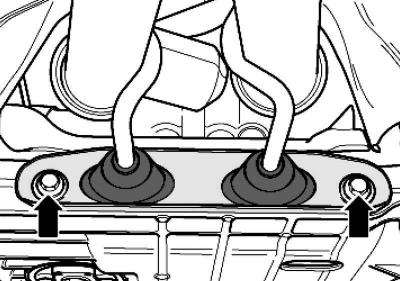

Pic. 2.89. Heat shield attachment

Remove the heat shield of the right drive shaft (pic. 2.89).

Continuation of assembly operations for all vehicles

Remove the right drive shaft and unscrew the left drive shaft from the gearbox.

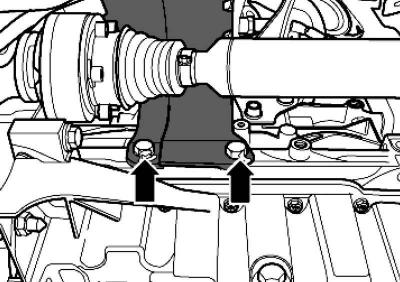

Pic. 2.90. Downpipe mount

Unscrew the nuts securing the intake pipe to the exhaust manifold and disconnect it from the exhaust manifold (pic. 2.90).

Note: The split elements in the downpipe must not be bent more than 10°.

Vehicles with engine codes BLX, BVX

Remove NO memory catalyst.

Remove the front propshaft tube.

Continuation of assembly operations for all vehicles

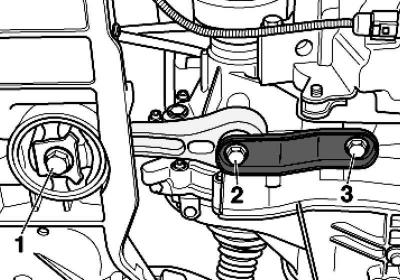

Pic. 2.91. oscillating bracket

Remove bolts 1-3 and remove the oscillating support (pic. 2.91).

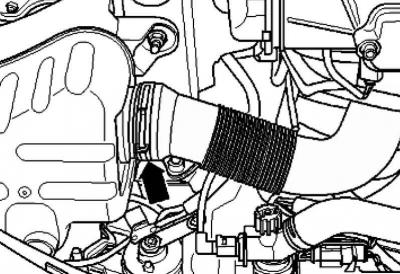

Pic. 2.92. air hose

Disconnect the air duct hose at the bottom of the expansion tank and remove it (pic. 2.92).

Remove the terminals, disconnect and release all other existing electrical wires from the engine/transmission.

Disconnect all connecting, vacuum, inlet hoses and coolant supply and outlet hoses from the engine.

Note: To avoid damage to the condenser, as well as pipes and hoses of the air conditioning circuit, make sure that the lines and hoses are laid without interference, kinks or kinks.

Note: To be able to remove and install the engine also without opening the refrigerant circuit.

Remove poly V-belt.

Unbolt the A/C compressor from the bracket.

Secure the A/C compressor to the locking bracket so that there is no stress on the refrigerant lines/hoses.

Vehicles with manual transmission

Remove the gearshift drive from the gearbox.

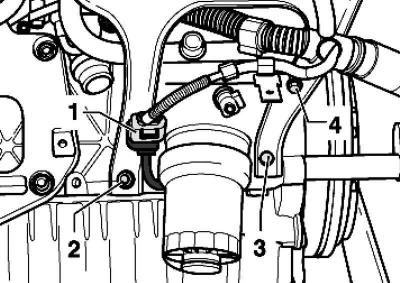

Pic. 2.93. Stretching and clutch slave cylinder

Remove stretch marks 1 (pic. 2.93).

Remove the clutch slave cylinder and set it aside, do not open the lines.

Attention: After dismantling the slave cylinder, do not press the clutch pedal. The slave cylinder may be damaged.

Vehicles with automatic transmission

Remove the selector cable from the gearbox.

Continuation of assembly operations for all vehicles

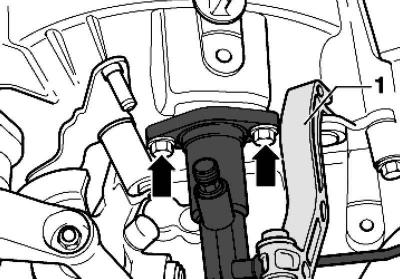

Pic. 2.94. Connecting plug

Pull connector 1 out of the holder (pic. 2.94).

Remove bolts 2-4.

Install the engine mount into the engine and transmission bracket.

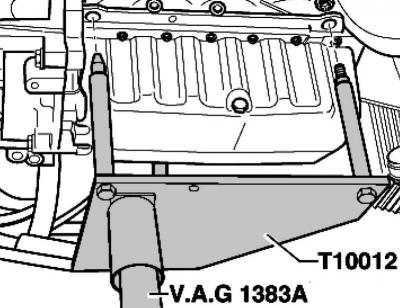

Pic. 2.95. Rack installation

Attach the engine stand, as shown in Figure 2.95, to the engine and screw it with a tightening torque of approximately 20 Nm to the cylinder block.

Screw the engine mount through the intake manifold support with an M10x25 mounting bolt with a torque of 20 Nm to the cylinder block.

Raise the engine and transmission slightly using an engine and transmission stand.

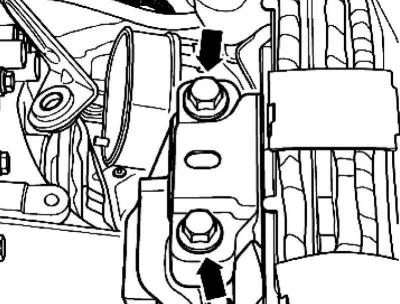

Pic. 2.96. Fastening of an arm of the top support of the engine

Unscrew the suspension of the power unit from the upper engine mount (pic. 2.96).

Pic. 2.97. Gearbox mount bracket

Unscrew the suspension of the power unit from the gearbox support (pic. 2.97).

Note: Use a ladder to loosen the fixing bolts.

Lower the engine and gearbox carefully to avoid damage to the body.

Carefully lower the engine and gearbox down.

Mounting the engine on the mounting stand

For installation work, the engine must be fixed to the engine and gearbox fixture.

Unbolt the gearbox from the engine.

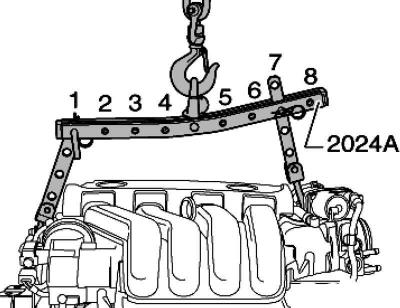

Pic. 2.98. Hanging device

Hang the hanger as follows and lift it up with a crane from the engine and transmission stand (pic. 2.98).

Pulley side 4th guide hole in position 1

Flywheel side 3rd guide hole in position 7

Caution: To avoid damage to the engine and vehicle, use special safety pins in the hooks and locking pins.

Holes 1-4 of the carrier bar point towards the belt pulleys.

The holes in the slats are counted from the hook.

Secure the engine to the engine and transmission bracket.

Engine installation

Installation is carried out in the reverse order, paying attention to the following.

Insert new dowels to align engine and gearbox into cylinder block.

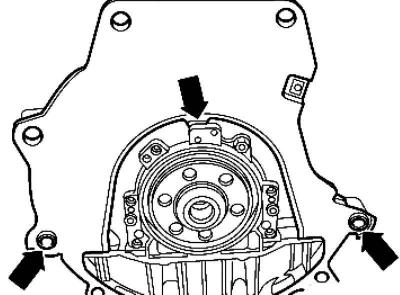

Pic. 2.99. Intermediate plate

Hang the intermediate plate on the sealing flange and push it onto the fitted bushings (pic. 2.99).

Vehicles with manual transmission

Lightly coat the input shaft teeth with grease.

Check and install clutch and clutch actuator.

Continuation of assembly operations for all vehicles

When installing the power unit (engine with gearbox) make sure there is enough space for the subframe and radiator.

Align the engine mount as follows:

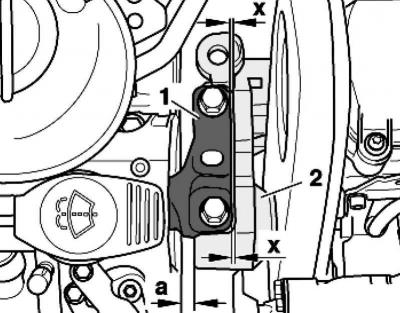

Pic. 2.100. Distance a between the engine support and the right side member

Between the engine support and the right side member, the distance a must be at least 10 mm (pic. 2.100).

The cast edge in the motor support 2 must be parallel to the bracket 1.

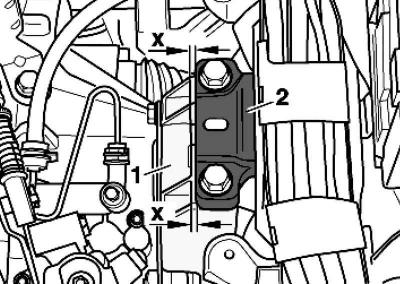

Pic. 2.101. Checking the parallelism of the edges of the bracket and the gearbox console

On the side of the gearbox, pay attention to the parallelism of the edges of the bracket 2 and the gearbox console 1 (pic. 2.101).

Install the rocker.

Install the right drive shaft and screw the left drive shaft to the gearbox.

All wheel drive vehicles

Install the front propshaft tube.

Vehicles with code letters BLR, BVY

Screw down the catalytic converter.

Vehicles with engine code BLX, BVX

Install a NOx memory catalyst.

Vehicles with engine code BLY, BVZ

Screw down the catalytic converter.

Vehicles with manual transmission

Install the shift actuator, adjust if necessary.

Install the hydraulic clutch slave cylinder.

Vehicles with automatic transmission

Install the selector cable and adjust if necessary.

Continuation of assembly operations for all vehicles

Install the air conditioning compressor.

Install poly V-belt.

Install a noise screen.

Connect the connector to the engine control unit.

Install the battery and battery holder frame.

Fill with coolant.

Take a test drive.

Then test the vehicle systems and eliminate any possible malfunctions.

Note: After clearing the fault memory, an OBD code must be generated.

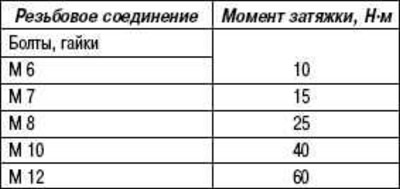

Tightening torques

Visitor comments