Removing

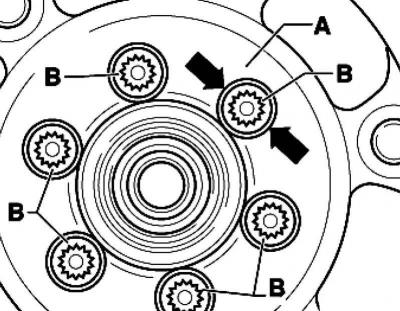

Pic. 2.147. Installation position of flywheel bolts

Rotate flywheel A so that bolts B are centered on the holes (pic. 2.147).

Note: To prevent damage to the dual-mass flywheel during removal, bolts B must not be removed with a pneumatic screwdriver. Bolts B may only be unscrewed by hand.

When loosening bolts B, make sure that the bolt head does not jam on the flywheel.

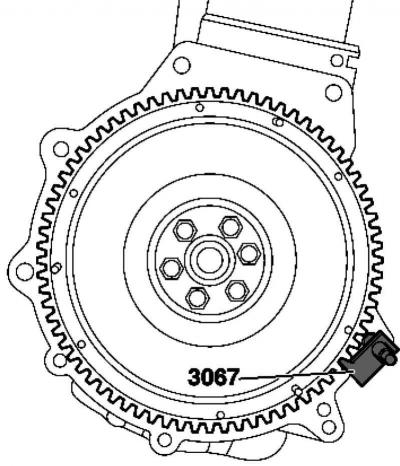

Pic. 2.148. Installing the counter support

Insert the counterholder into the hole on the cylinder block (pic. 2.148).

Mark the position of the flywheel relative to the engine.

Open the flywheel.

Installation

Installation is carried out in the reverse order, paying attention to the following.

The bolts must be replaced.

Tightening torque: dual-mass flywheel to crankshaft - 60 Nm +90° (1/4 turn)

Visitor comments