Unscrewing and screwing the driven disk

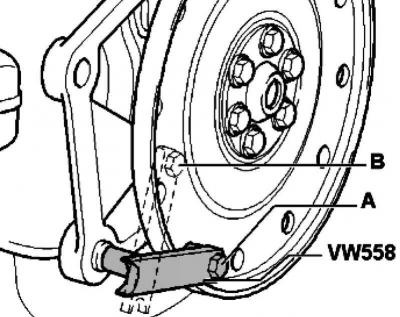

Pic. 2.149. Scheme of fixing the counterholder

Secure the counterholder with an M8x45 hexagon bolt on the driven disk. Install two M10 hexagon nuts between the counter support and the driven plate (pic. 2.149).

Mounting location of counterholder A for unscrewing, B for tightening.

Installation of a slave disk

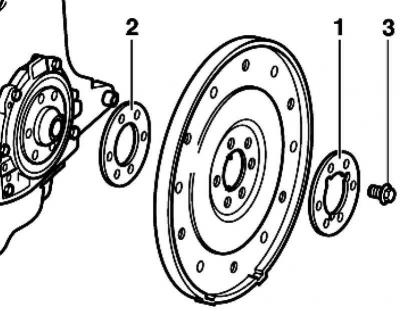

Pic. 2.150. Drive Drive Components

Install driven disc using slotted washer 1 (pic. 2.150).

Insert and tighten with a torque of 30 Nm new bolts 3.

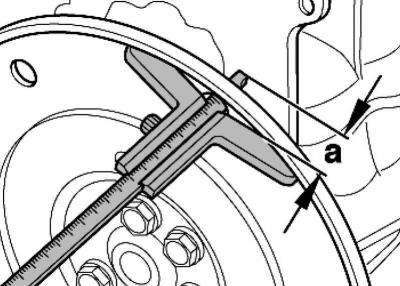

Pic. 2.151. Measuring the amount of protrusion of the driven disk

Measure A in three places and calculate the average value (pic. 2.151).

Nominal value 19.5–21.1 mm.

Note: It is measured through the hole in the driven plate to the milled surface of the cylinder block.

Note: If the nominal value is not reached

Note: Dismantle the driven disk again using compensation washer 2 (pic. 2.150). Tighten bolts 3 again with a torque of 30 Nm.

Tighten the bolts to a torque of 60 Nm and tighten by 90° (1/4 turn) (tightening can be performed in several approaches).

Visitor comments