Note: When rotating the camshaft, the crankshaft must not be at TDC. There is a risk of damage to the valves and piston head.

Note: The engine should feel warm to the touch.

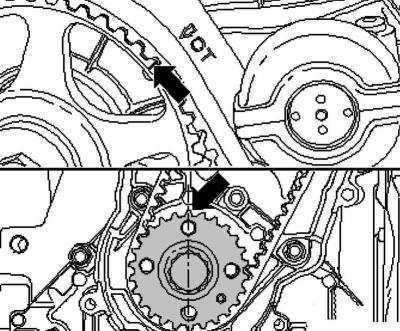

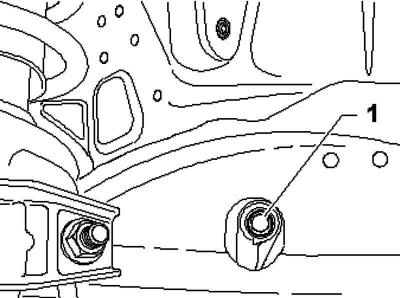

Pic. 2.102. TDC marks

Set the camshaft and crankshaft to the TDC mark (pic. 2.102).

Put the toothed belt on the crankshaft pulley (follow the direction of travel).

Install the toothed belt in the following sequence: tension roller, camshaft pulley, cooling system pump, and lastly, the guide roller.

Note: Make sure that the tension roller is in the correct position in the cylinder head.

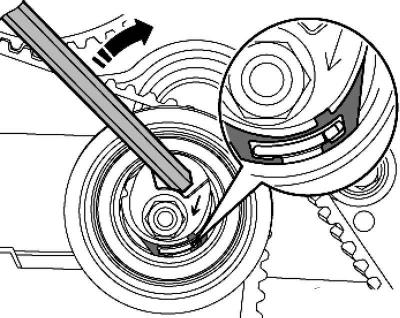

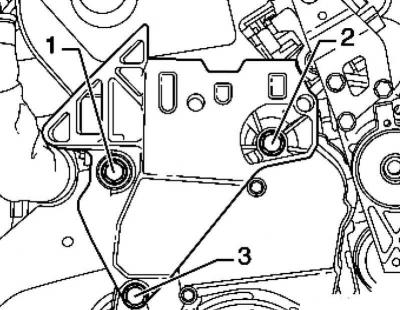

Pic. 2.103. Toothed belt tension

Spend a tension of a gear belt. To do this, turn the hexagon socket screw on the eccentric to the right (arrow direction), until the slot is above the ledge (toothed belt over tightened) (pic. 2.103).

Release the toothed belt again.

Then tension the toothed belt until the slot and lip are opposite each other.

Tighten the fixing nut to 25 Nm.

Turn the crankshaft further two turns in the direction of engine rotation until the engine is again at TDC. It is important that at the last 45° (1/8 turn) rotation proceeded without interruption.

Recheck the toothed belt tension. Specified value The ledge and slot must be opposite each other.

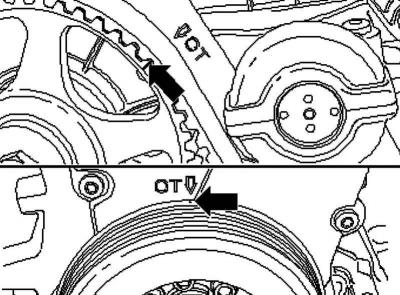

Check valve timing. The labels must match.

If the marks do not match, repeat the installation of the valve timing.

If the marks match, bring the engine mount bracket into position.

Note: Do not install engine mount bracket bolts yet. The engine support bracket must «free» stand between the engine and the spar.

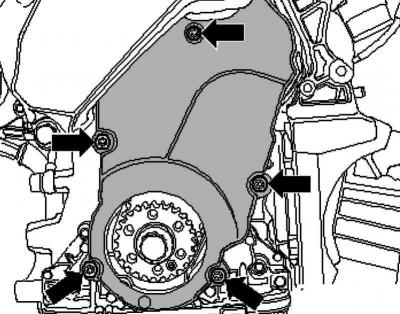

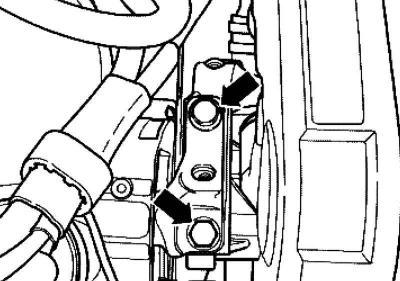

Pic. 2.104. Lower toothed belt guard

Install lower toothed belt guard (pic. 2.104).

Install the damper on the pulley with new bolts. Tightening torque 10 Nm + tighten by 90°.

Pic. 2.105. Tags

Check the valve timing again. Labels must match (pic. 2.105).

Tighten both top toothed belt guard bolts.

Install the engine support bracket to the cylinder block and tighten the top bolt.

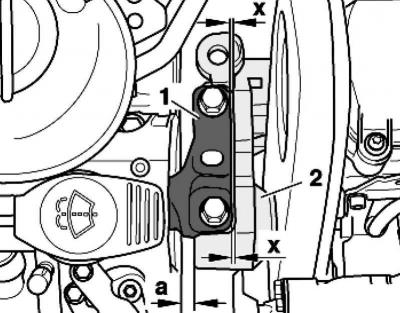

Pic. 2.106. Middle bolt

Lower the engine with the yoke until the middle bolt 1 can be tightened through the hole in the wheel arch (pic. 2.106).

Then insert the bottom bolt and tighten all bolts to 45 Nm.

Pic. 2.107. Bolts of fastening of an arm of a support of the power unit

Note: Pay attention to the difference in bolt length. Bolt 3 is about 25 mm shorter than bolts 1 and 2 (pic. 2.107).

Install the power unit support in the area of the engine.

Pic. 2.96. Fastening of an arm of the top support of the engine

Screw in the bolts of the power unit support in the area of the engine and the engine support bracket, for which the supporting surfaces should be brought into contact using a traverse (pic. 2.96).

Straighten the engine mount as follows.

Pic. 2.100. Distance a between the engine support and the right side member

Distance A between the engine support bracket and the right side member must be at least 10 mm (pic. 2.100).

The cast edge on the engine support bracket 2 must be parallel to foot 1.

Tighten the bolts of the power unit support in the area of the engine and the engine support bracket.

Remove the traverse.

Install the V-ribbed belt tensioner.

Install poly V-belt.

Reconnect the fuel and ventilation lines. Make sure the quick couplings are securely fastened.

Install the expansion tank of the cooling system.

Reattach the pendulum support to the gearbox.

Install the front right fender liner.

Install soundproofing.

Pic. 2.108. Location of rubber bumpers

Install rubber hood bumpers (pic. 2.108).

Insert the #SD34 fuse back into the fuse box.

Install the engine cover.

Visitor comments