Verification conditions

The minimum battery voltage should be 11.5 V.

Fuse SD34 in the fuse box on the right side of the front panel should be good.

The fuel pump control unit must be OK.

BLR, BLX, BLY engines

The low fuel pressure sensor should be good.

Checking procedure

Remove the rear seats.

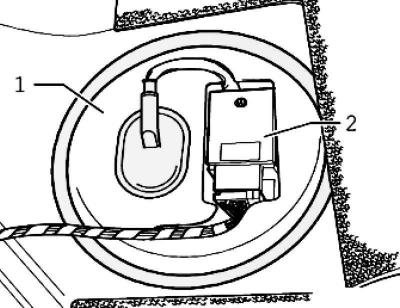

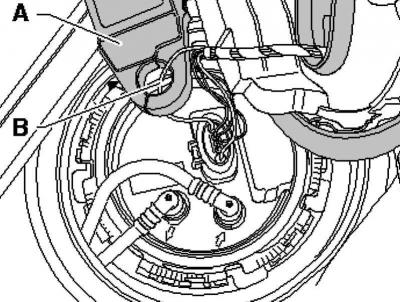

Pic. 2.204. Fuel supply module cover and control unit

Remove cover 1 with fuel pump control unit 2 from the fuel supply module (pic. 2.204).

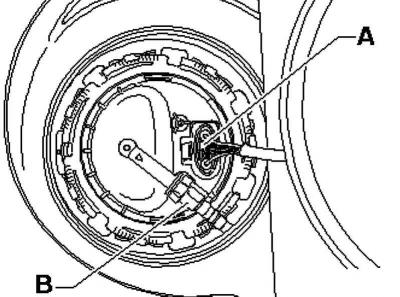

Pic. 2.205. Plug and fuel line

Disconnect the 5-pin plug from the flange (pic. 2.205).

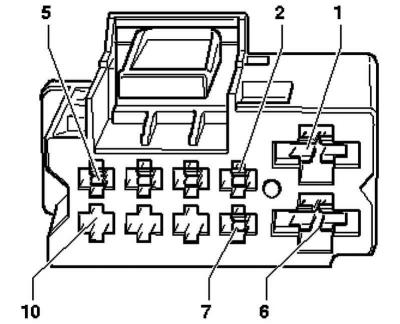

Pic. 2.209. Fuel pump connector

Connect remote control via auxiliary wires to pin 1 (+) fuel pump and to pin 1 (+) – 10 pin connector (pic. 2.209).

Connect pins 6 (–) – 10 pin connector and 5 (–) fuel pump with an auxiliary wire from the auxiliary measuring instrument kit.

Unscrew the cap of the filler neck of the fuel tank.

Disconnect the fuel supply line 2 and place a rag under the flowing fuel.

Note: To disconnect the fuel line, press the retaining ring.

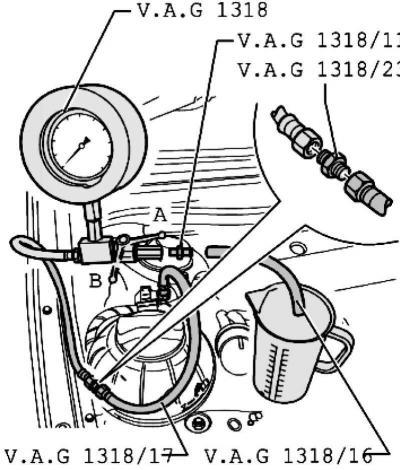

Pic. 2.210. Pressure gauge connection

Connect a pressure gauge with a double fitting and a set of adapters to the fuel supply line (pic. 2.210).

Push the hose adapter onto the pressure gauge adapter and keep it pointed into the measuring vessel.

Attention: When opening the tap, there is a risk of fuel splashing; Wear safety goggles and gloves to avoid injury and skin contact. Place a container under the open pressure gauge connection.

Open the pressure gauge valve. The lever indicates throughput direction A.

Activate the remote control. In this case, slowly close the valve until the pressure gauge shows 4 bar overpressure. After that, do not change the position of the valve.

Empty the measuring vessel.

The performance of the fuel pump depends on the voltage of the battery. Therefore, connect the multimeter with wires from the set of auxiliary measuring tools to the battery.

Turn on the remote control for 30 si while measuring the battery voltage.

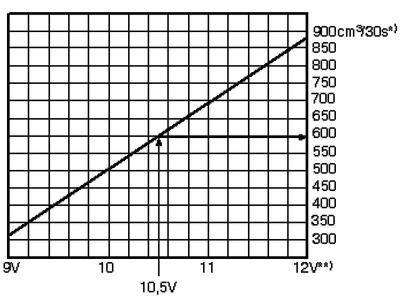

Pic. 2.211. Fuel Rating Chart

Compare the amount of fuel received with the nominal value (pic. 2.211).

Example:

During the battery test, a voltage of 12.5 V is measured. Since the voltage at the pump is 2 V less than the battery voltage, the minimum delivery volume is about 580 cm3/30 s.

*) – Minimum productivity, cm3/30 s

**) – Voltage at the fuel pump when the engine is not running and the pump is running (about 2 V less than the battery voltage).

If the specified pressure is not reached, check the fuel line for kinks or blockages.

If no problem is found, remove the fuel delivery module and check the strainer for debris.

If no errors are found here either, replace the fuel filter flange

Repeat check.

If the nominal value is not reached again, the fuel pump is faulty, replace the fuel supply module.

Nominal fuel delivery has been achieved, but a fuel system failure is still possible (e.g. temporary power failure)

Check the current consumption of the fuel pump.

Energy check

Checking procedure

Remove the rear seats.

Remove cover 1 with fuel pump control unit 2 from the fuel supply module (pic. 2.204).

Pic. 2.212. Installation of heat meters

Connect the multimeter with clamp meter A to wire B, pin 1 of the 5-pin connector (pic. 2.212).

Start the engine and let it idle.

Measure the power consumption of the fuel pump. Rated value max. 9 A.

Note: If the error in the power system occurs only from time to time, then the check can also be carried out during a test drive, however, a second specialist is required for this.

If the power consumption is exceeded, then

the fuel pump is faulty, replace the fuel supply module.

Visitor comments