Note: During further operations, the ground wire must be disconnected from the battery.

Note: The engine is removed with the gearbox down.

Note: Leave the key in the ignition to prevent the steering wheel from locking.

Note: It is recommended to remove the front wheels before starting to dismantle the power unit. Due to this, the car can be lowered on the lift, leaving a few centimeters between the casings of the brake discs and the floor. Thus, during operation, optimal reach of all components in the engine compartment will be ensured.

Note: After installing the motor, it is necessary to reinstall any cable ties removed or sheared when dismantling the motor.

Note: To avoid damage to removed parts, use a container for removed parts.

Note: Some components in this vehicle cannot be removed or are difficult to remove without removing the engine. Therefore, before removing the engine, it is necessary to identify all defective parts and replace them after removing the engine.

Attention: When carrying out all assembly work, in particular in the engine compartment, due to the tight layout, pay attention to the following.

Attention: Highways of all types (e.g. fuel, hydraulic, activated charcoal absorber, cooling systems, air conditioning circuits, brake lines, vacuum hoses), as well as electrical wires must be laid as they were originally laid.

Caution: Keep free space for all moving and hot components.

Before removal, interrogate the fault memory of all control units.

Disconnect the ground wire from the battery with the ignition off.

Remove the engine cover.

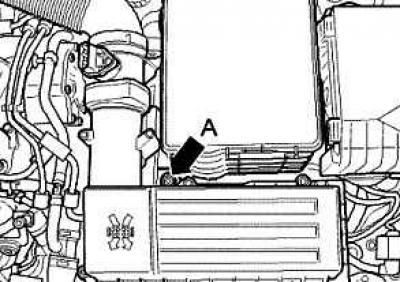

Pic. 2.253. Screw of fastening of the case of the air filter

Loosen screw A, pull the air filter housing up out of the mount (pic. 2.253).

Remove the air filter housing together with the air mass meter and connecting tube.

Disconnect all necessary vacuum hoses or, if present, the plug connection on the solenoid valve block.

Remove the battery and battery holder frame.

Remove the wiper arms.

Remove the water box cover.

Vehicles without anti-theft alarms

Unlock the connectors from the engine control unit and disconnect them.

Vehicles with anti-theft alarms

Unlock the connectors from the engine control unit and disconnect them.

Continuation of assembly operations for all vehicles

Remove the wiring harness/engine control unit grommet.

Open the conduit latches.

Remove the engine wiring harness from the conduit on the side member and lay it on the engine.

Remove the fuel supply line, fuel return line and coolant hose.

Caution: Fuel and fuel lines may be hot.

Caution: In addition, the fuel system is pressurized Before opening the system, put a rag around the connections and relieve the pressure by slowly unwinding these connections

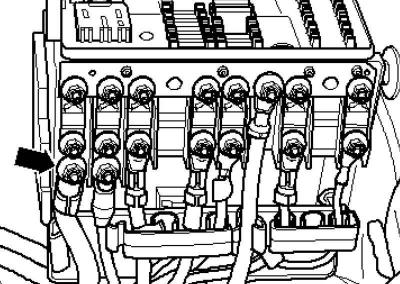

Pic. 2.85. Fastening the generator cable to the fuse box

Remove the cable from the car's central distribution box (pic. 2.85).

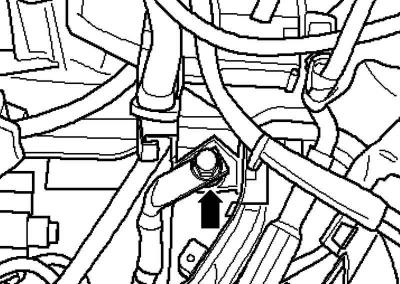

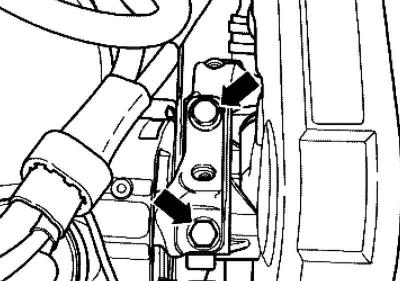

Pic. 2.86. Earth cable fastening

Unscrew the mass cable from the spar (pic. 2.86).

Set aside the cables.

Remove the terminals, disconnect and release all other existing electrical wires from the engine/transmission.

Disconnect from the engine all connecting, vacuum and inlet hoses from the engine.

Front wheel drive vehicles

Disconnect the gearshift drive from the gearbox.

All wheel drive vehicles

Remove the gearshift drive from the gearbox.

Continuation of assembly operations for all vehicles

Remove the hydraulic clutch slave cylinder.

Remove soundproofing.

Disconnect the plug on the oil level and temperature sensor.

Disconnect the harness holder from the oil level and oil temperature sensor on the subframe.

Drain the coolant.

Move radiator frame to service position.

Completely remove the exhaust pipes from the auxiliary heater.

Remove the coolant hoses from the auxiliary heater.

Disconnect all other cooling system hoses from the engine.

Remove the right drive shaft and unscrew the left drive shaft from the gearbox.

All wheel drive vehicles

Remove the front propshaft tube.

Vehicles with particle filter

Unscrew the front exhaust pipe/front muffler connecting clamp.

Remove the subframe together with the steering gear.

Note: The engine is removed downwards with the particulate filter installed.

Vehicles without particle filter

Unscrew the exhaust pipe from the turbocharger, unscrew the double clamp and remove the exhaust pipe.

Continuation of assembly operations for all vehicles

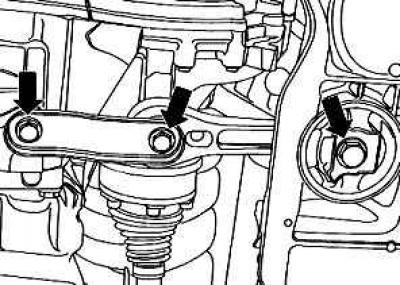

Pic. 2.254. Oscillation mounting bolts

Unscrew the rocker (pic. 2.254).

To remove and install the engine without depressurizing the air conditioning circuit, remove the V-ribbed belt.

Unbolt the A/C compressor from the bracket.

Attach the A/C compressor to the radiator frame so that the pipes/hoses of the A/C circuit are not under tension.

Note: To avoid damage to the condenser and the piping and hoses of the A/C circuit, make sure that the lines and hoses are routed without tension, kinks or kinks.

Screw the engine retainer with a fixing nut and bolt M10x25/8.8 with a tightening torque of approximately 40 Nm to the cylinder block.

Install the engine retainer in the engine and transmission rack.

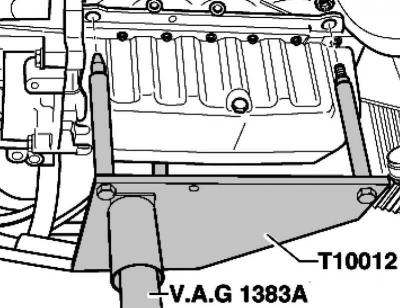

Pic. 2.95. Rack installation

Raise the engine and transmission slightly using an engine and transmission stand (pic. 2.95).

Note: Use a ladder to remove the mounting bolts.

Pic. 2.96. Fastening of an arm of the top support of the engine

Unscrew the cushions on the side of the engine above the engine mount (pic. 2.96).

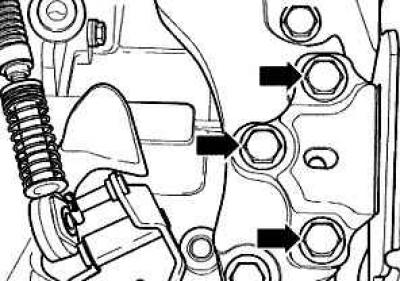

Pic. 2.255. Bolts of fastening of a pillow of the engine

Unbolt the cushions on the side of the gearbox from the gearbox bracket (pic. 2.255).

Lower the engine with the gearbox down.

Note: Lower the engine and gearbox carefully to avoid damage to the body.

Mounting the engine on the mounting stand

For assembly work, the engine must be secured with the engine and gearbox clamp to the fixture of the mounting stand or to the engine and gearbox clamp.

Work order

Separate the gearbox.

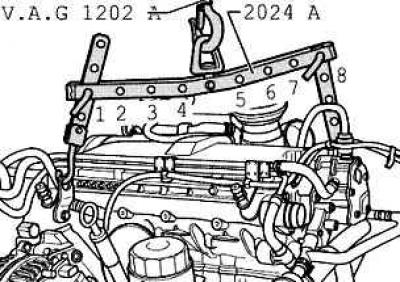

Pic. 2.256. Engine suspension

Hang the hanger properly and lift the engine with a crane or a crane from the engine and transmission stand (pic. 2.256).

On the side of the belt pulleys 2, the guide hole is in position 1.

Flywheel side 4-hole guide in position 8.

Caution: Use safety pins on hooks and locking pins.

Note: Holes 1-4 of carrier bar point towards belt pulleys.

The holes in the slats are counted from the hook.

Secure the engine with the engine and gearbox clamp to the jig of the mounting stand or to the engine and gearbox clamp.

Installation instructions

Installation is carried out in the reverse order, taking into account the following.

Check the clutch release bearing for wear, replace if necessary.

Lightly lubricate the gearing of the drive shaft with grease.

Check the presence of fitted bushings in the cylinder block for centering the engine / gearbox, install them if necessary.

Mount the motor support free of internal stresses (shake), if necessary, unscrew the engine mount from the body.

All wheel drive vehicles

Install the front propshaft tube.

Continuation of assembly operations for all vehicles

Fill with coolant.

Follow the safety precautions for test drives.

Carry out a test drive and then interrogate the fault memory.

Tightening torques

Visitor comments