Removing

Disconnect the ground wire from the battery with the ignition off.

Remove the engine cover.

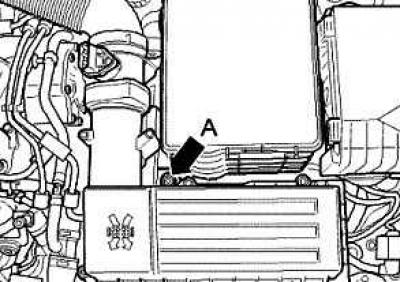

Pic. 2.253. Screw of fastening of the case of the air filter

Loosen screw A pull the air filter housing up out of the mount (pic. 2.253).

Remove the air filter housing with air mass meter and connecting tube.

Remove battery.

Remove the noise screen.

Drain the coolant.

Disconnect the return and supply fuel lines, as well as the cooling system tube from the cylinder head.

Before removing the cylinder head, bleed the fuel using a hand-held vacuum pump with accessories and a container to draw fluid from the tandem pump.

Remove poly V-belt.

Remove the intercooler/intake pipe connecting hose.

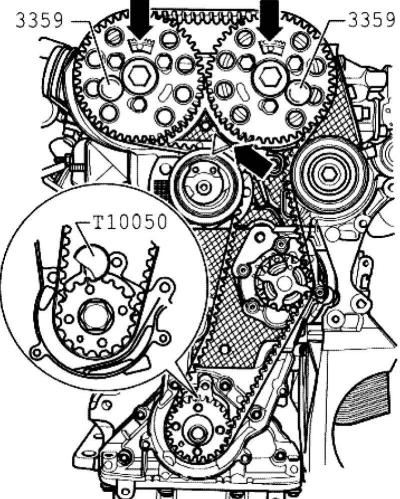

Pic. 2.294. Alignment of the marks on the toothed belt cover and camshaft

Unscrew the vibration damper and remove it from the crankshaft. Lock the crankshaft with a crankshaft lock or crankshaft lock at the TDC position of the first cylinder (pic. 2.294).

Vehicles without particle filter

Unscrew the exhaust pipe from the turbocharger, unscrew the double clamp and remove the exhaust pipe.

Vehicles with particle filter

Remove the particle filter.

Continued job description for all vehicles

Remove the turbocharger support and oil return pipe from the turbocharger.

Unscrew the fixing nut of the tension roller and loosen the tension of the toothed belt.

Remove the tension roller fixing nut.

Remove the camshaft gears and hubs.

Unscrew the Hall sensor on the cylinder head.

Unscrew the fixing bolts of the lower part of the toothed belt cover on the cylinder head.

Unscrew the holder of the vacuum reservoir and oil dipstick.

Remove the connecting tube of the exhaust gas recirculation system.

Remove the turbocharger oil supply line.

Remove/disconnect all other electrical wires present from the cylinder head.

Disconnect from a head of the block of cylinders all connecting, vacuum, inlet hoses and hoses of giving and removal of a cooling liquid.

Remove the cylinder head cover.

Remove the roller arm axle and the inner mounting bolts of the support module.

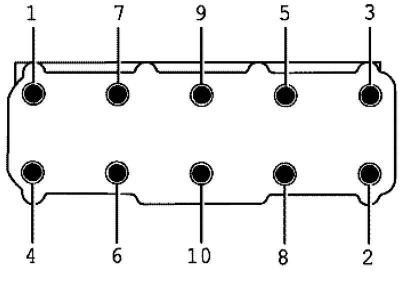

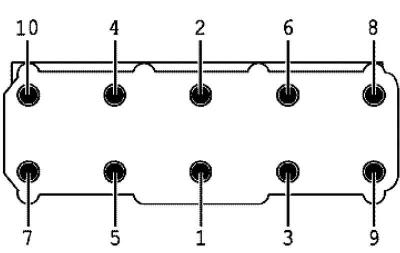

Pic. 2.302. The sequence of unscrewing the cylinder head bolts

Follow the sequence when unscrewing the cylinder head bolts (pic. 2.302).

Slightly lift and remove the cylinder head from the engine past the toothed belt guard.

Note: Timing belt tensioner remains on engine mount.

Note: Handle the cylinder head very carefully to avoid damage.

Installation

Install cylinder head gasket with marking facing up.

Note: Always replace the cylinder head bolts.

Note: When repairing, remove any remaining sealant from the cylinder head and cylinder block. Avoid long scratches or gouges. When using sandpaper, its grit should be at least 100.

Note: Remove sanding and sanding residue.

Note: A new cylinder head gasket should be removed from the packaging just before installation.

Note: Damage to the silicone layer and bellows leads to loss of tightness.

Note: Before installing the cylinder head, remove the crankshaft retainer or crankshaft retainer and rotate the crankshaft against the direction of engine rotation until all pistons are evenly below TDC.

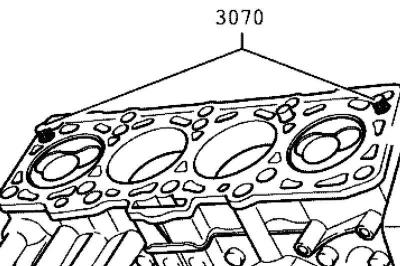

Pic. 2.303. Centering pins

For centering, screw the guide bolt into the outer holes on the suction side (pic. 2.303).

Note: When installing the cylinder head, the tension roller must be installed on the spacer bolt.

Install the cylinder head, insert the remaining 8 cylinder head bolts and tighten them by hand.

Unscrew the guide bolt with a screwdriver through the hole and install the cylinder head bolts.

Then tighten the cylinder head bolts in 4 stages in the following sequence:

- 1 - tighten with a torque wrench;

- - stage 1 = 35 Nm;

- - stage 2 = 60 Nm;

- 2 - then rotate with a regular key;

- - step 3 = tighten 1/4 turn (90°);

- - step 4 = tighten 1/4 turn (90°).

Attach the lower part of the timing belt cover to the cylinder head.

Pic. 2.304. The sequence of tightening the cylinder head bolts

Screw the Hall sensor to the cylinder head.

Install the hubs and camshaft gears.

Lock the camshafts with locking pins for the diesel injection pump

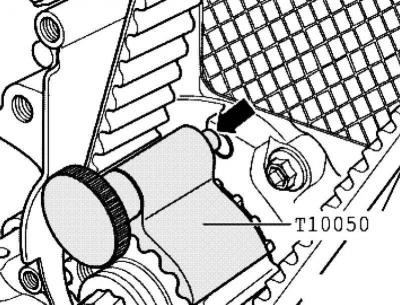

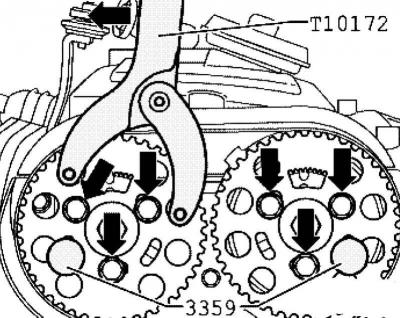

Pic. 2.301. Retainer pin

Rotate the crankshaft in the direction of rotation of the engine shaft and set it to TDC, fix the crankshaft with the crankshaft lock or crankshaft lock (pic. 2.301).

Center the camshaft gears in the slots.

Place the toothed belt first on the exhaust camshaft sprocket, then on the intake camshaft sprocket.

Establish a fixing nut of a tension roller.

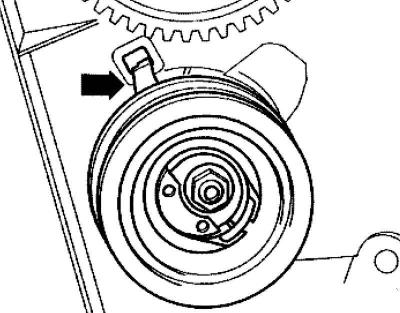

Pic. 2.298. Proper seating of the tension roller

Note: Make sure that the tensioning pulley is properly seated at the rear of the toothed belt cover (pic. 2.298 Note:).

Pic. 2.299. Tension roller rotation

Then rotate the idler with a wrench in the direction of the arrow until the arrow is in the middle of the base plate gap (pic. 2.299).

Make sure that the fastening nuts do not rotate.

Fix the tension roller in this position and tighten the tension roller fixing nut, as follows, with a torque of 20 Nm and tighten by 45° (1/8 turn).

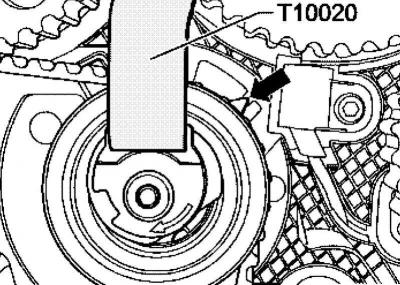

Pic. 2.300. Installing the counter support

Establish a countersupport, as it is shown in drawing 2.300. Press the counterholder in the direction of the arrow and clamp the camshaft gears.

Tighten the camshaft gear mounting bolts in this position with a torque of 25 Nm.

Remove lock pins, crankshaft retainer or crankshaft retainer.

Make min. 2 revolutions of the crankshaft in the direction of rotation of the engine shaft and again set the first cylinder before the position of the top dead center.

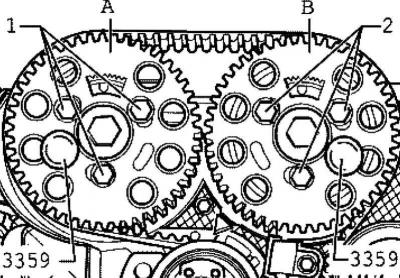

Pic. 2.296. Fixing hubs with pins

Secure hub A against rotation in the direction of the motor shaft with a locking pin (pic. 2.296).

Check that the hub B is fixed with the locking pin.

The crankshaft was fixed with a crankshaft lock.

The arrow of the tension roller must be in the middle or max. 5 mm to the right of the base plate spacing.

Further installation is carried out in the reverse order. In doing so, the following must be taken into account.

Establish an axis of roller levers.

Install the block head cover.

Install the oil supply line.

Install poly V-belt.

Fill with coolant.

Carry out a test drive and interrogate the fault memory.

Visitor comments