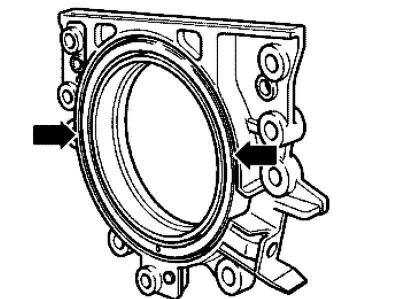

Pressing out the sealing flange with the sensor wheel

Remove the gearbox.

Remove flywheel.

Remove the intermediate plate.

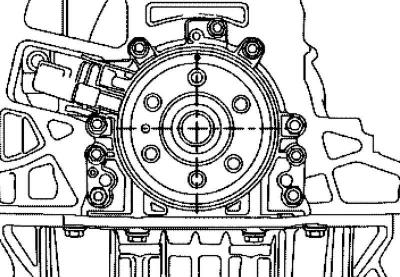

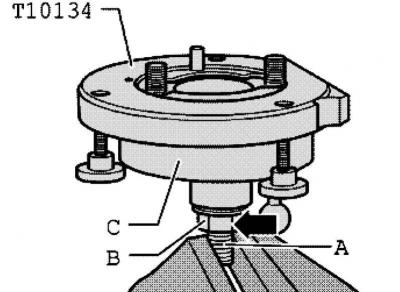

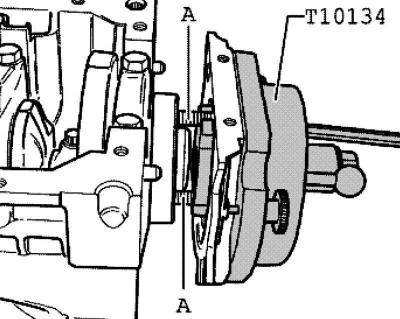

Pic. 2.263. Installing the crankshaft at TDC

Put the crankshaft in the TDC position of the cylinder as shown in Figure 2.263.

Remove the oil pan.

Note: For a clearer illustration of the installation steps, they are shown with the engine removed.

Note: Mounting operations with engine installed and gearbox removed are the same.

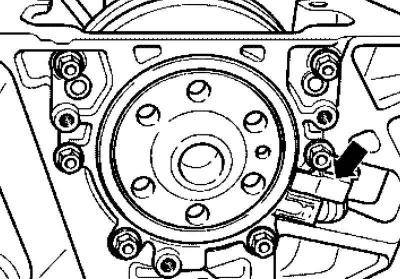

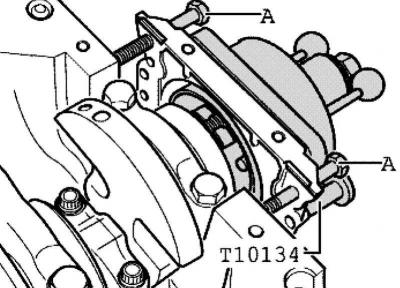

Pic. 2.264. Removing the engine speed sensor

Remove the engine speed sensor (pic. 2.264).

Unscrew the fixing bolts of the sealing flange.

Note: The sealing flange and sensor wheel are pressed from the crankshaft together with three M6x35mm bolts.

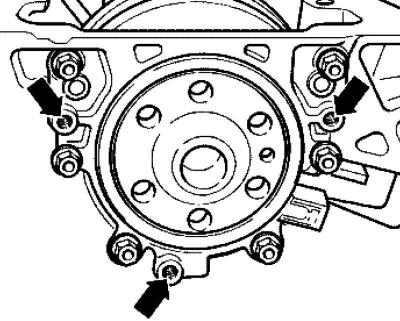

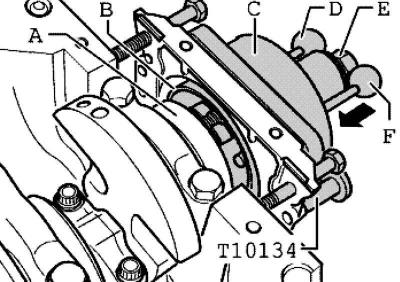

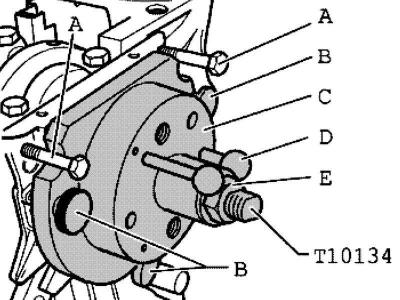

Pic. 2.265. Sealing flange mounting bolts

Screw three M6 x 35 mm bolts into the threaded holes of the sealing flange (pic. 2.265).

Alternating, twist (maximum one 1/2 turn (180 °) for each bolt) bolts into the sealing flange and press it together with the sensor wheel from the crankshaft.

Pressing in the sealing flange with the sensor wheel

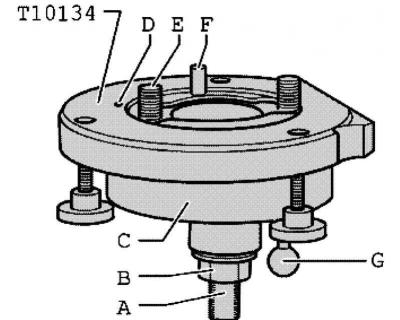

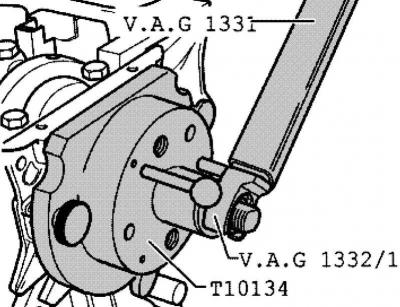

Pic. 2.266. Mounting aid: A - pressure surface; B - hex nut; C - mounting cup; D - locking pin; E - screw with an internal hexagon; F - guide pin for diesel engines (black handle); G - guide pin for gasoline engines (red handle)

The mounting tool is positioned in the correct position relative to the crankshaft by a guide pin that fits into the crankshaft bore (pic. 2.266).

Note: The PTFE packing flange has a lip support ring. This support ring acts as a mounting sleeve, so it must not be removed before installation.

Note: Once removed from the packaging, the flange and sensor wheel must not be separated or rotated.

Note: The encoder wheel is positioned in the mounting position by locking onto the pin of the mounting tool.

Note: The sealing flange and oil seal are one piece and can only be replaced together with the sensor wheel.

Installing the oil seal with the sensor wheel on the mounting tool (A)

Unscrew the hexagon nut B almost to the clamping surface A of the spindle.

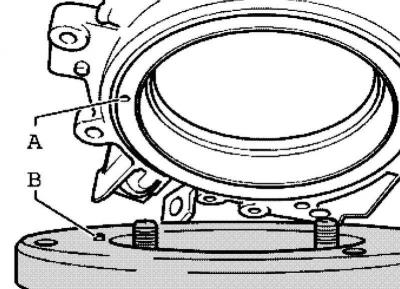

Pic. 2.267. Installing the Mounting Tool in the Vise

Clamp the mounting tool at the clamping surface A of the lead screw in a vise (pic. 2.267).

Press mounting cup C down to rest on hex nut B.

Screw the hex nut onto the lead screw until the inside of the mounting jig and the mounting cup are at the same level.

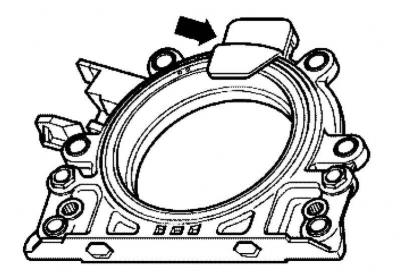

Pic. 2.268. Protective clip

Remove the protective clip from the new sealing flange (pic. 2.268).

Note: The sensor wheel must not be removed from the sealing flange or rotated.

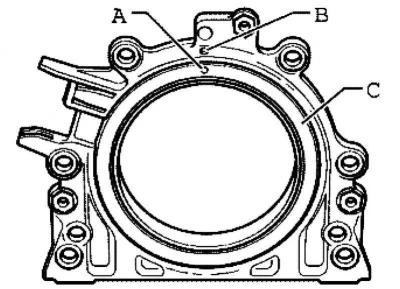

Pic. 2.269. Fixing hole and flange mark

The fixing hole A in the sensor wheel C must match the mark B on the flange (pic. 2.269).

Lay the flange face down on a clean, flat surface.

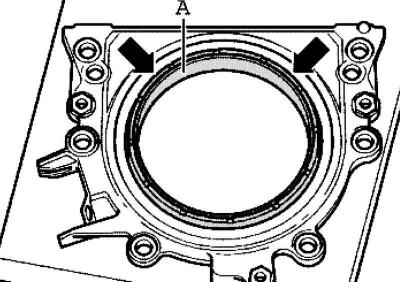

Pic. 2.270. Support ring installation

Press the lip support ring A downwards in the direction of the arrow until it rests on a flat surface (pic. 2.270).

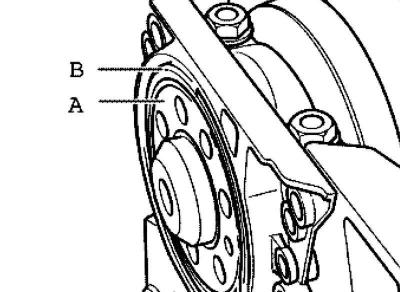

Pic. 2.271. Wheel edge sensor

The top edge of the sensor wheel and the front edge of the flange must be at the same level (pic. 2.271).

Pic. 2.272. Installing the Flange on the Mounting Tool

Place the flange face down on the mounting tool so that the locking pin B fits into the hole A of the sensor wheel (pic. 2.272).

Note: Make sure the flange lies flat on the mounting fixture.

Pic. 2.273. Tightening the Mounting Tool Bolts

Press the flange and lip support ring B while tightening the three knurled bolts A against the surface of the mounting fixture so that the locking pin cannot slip out of the hole in the sensor wheel (pic. 2.273).

Note: When mounting the flange, care must be taken to ensure that the sensor wheel remains fixed in the mounting fixture.

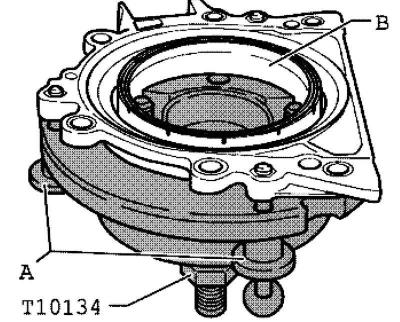

Installing a mounting tool with a sealing flange on the crankshaft flange (IN)

The crankshaft flange must be free of oil and grease.

The engine is at TDC cyl. 1.

Unscrew hex nut B to the end of the lead screw.

Pic. 2.274. Hex nut and mounting cup

Press the lead screw of the mounting tool in the direction of the arrow until the hex nut B rests on the mounting cup A (pic. 2.274).

Align the mounting cup with the flat side to the joint between the engine crankcase and the oil pan.

Pic. 2.275. Attaching the mounting tool to the crankshaft flange

Fasten the mounting tool with hexagon socket bolts A to the crankshaft flange (pic. 2.275).

Note: Screw hexagon socket bolts A with about 5 threads into the crankshaft flange.

Pic. 2.276. Screwing in screws to correct the direction of the sealing flange

Screw two bolts M7x35 mm A into the cylinder block to guide the sealing flange (pic. 2.276).

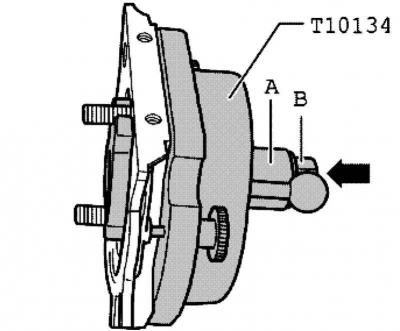

Screwing the mounting tool to the crankshaft flange (WITH)

Pic. 2.277. Screwing on the mounting device

Slide the mounting cup C by hand in the direction of the arrow so that the support ring of the working lip B is pressed against the crankshaft flange A (pic. 2.277).

Insert guide pin for diesel engines (black handle) F into the crankshaft hole. As a result, the encoder wheel is finally brought into the installation position.

Note: Guide pin for petrol engines (red handle) D Do not insert into the threaded hole of the crankshaft.

Hand-tighten both hexagon socket screws of the mounting tool.

Screw the hexagon nut E onto the spindle until it is pressed against the mounting cup C.

Pressing the sensor wheel onto the crankshaft flange using a mounting tool (D)

Pic. 2.278. Tightening the Hex Nut of the Mounting Tool

Tighten the hex nut of the mounting tool with a torque wrench and a socket with a tightening torque of 35 Nm (pic. 2.278).

Note: After tightening the hex nut to 35 Nm, there should still be a slight gap between the cylinder block and the sealing flange.

Checking the mounting position of the sensor wheel on the crankshaft (E)

Unscrew the hexagon nut E to the end of the spindle.

Remove both bolts A from the cylinder block.

Remove the three knurled screws B from the sealing flange.

Remove the mounting tool.

Remove the lip support ring.

Pic. 2.279. Precise sensor position

The sensor wheel assumes an exact mounting position on the crankshaft when there is a distance A of 0.5 mm between crankshaft flange A and sensor wheel B (pic. 2.279).

Attach the caliper to the crankshaft flange.

Pic. 2.280. Measuring the distance between the crankshaft flange and the sensor wheel

Measure the distance a between the crankshaft flange and the sensor wheel (pic. 2.280).

If distance A is insufficient, press the sensor wheel deeper.

When distance a has been reached, screw in new sealing flange fixing bolts, alternating crosswise with a torque of 15 Nm.

Install the engine speed sensor and tighten the mounting bolt to 5 Nm (pic. 2.264).

Install the oil pan.

Install the intermediate plate.

Fasten the flywheel with new bolts. Tighten the mounting bolts with a tightening torque of 60 Nm + 1/4 turn (90°).

Visitor comments