Remove the air filter housing assembly if it is in the battery area.

Remove the battery, cover and battery bracket.

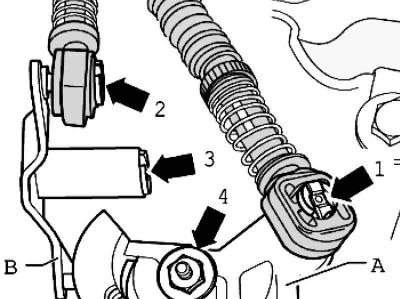

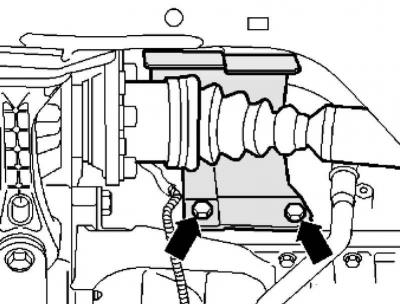

Pic. 3.23. Fastening of cables of coupling and the lever of a gear change

Remove lock washer 1 for shift cable from shift lever A (pic. 3.23).

Remove the lock washer 2 for the gear selection cable from the intermediate lever B (pic. 3.23).

Remove the shift cable and select cable from the trunnions.

Remove the lock washer 3 from the intermediate lever B and remove the lever.

Remove gearshift lever A by unscrewing nut 4 (pic. 3.23).

Disconnect the cable stop from the gearbox.

Then tie up the shift cable and select cable at the top.

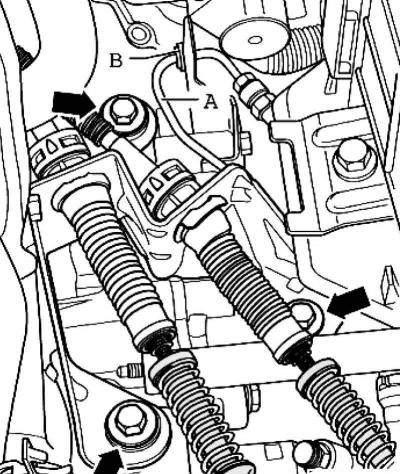

Pic. 3.24. Gearbox Bracket &Tubular Hose

Remove the bracket B from the gearbox and pull it off the pipe-hose line A (pic. 3.24).

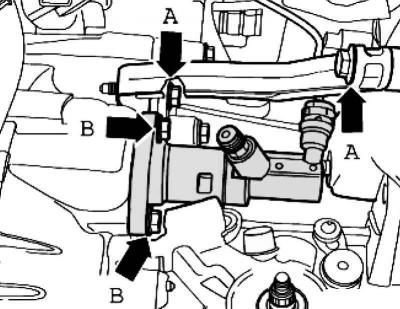

Pic. 3.25. Clutch slave cylinder mounting

Then remove the gearbox support A (pic. 3.25).

Remove the clutch slave cylinder B and set it aside, secure with wire, do not open the lines.

Attention: Do not press the clutch pedal any more.

Remove the ground wire from the upper bolt securing the gearbox to the engine.

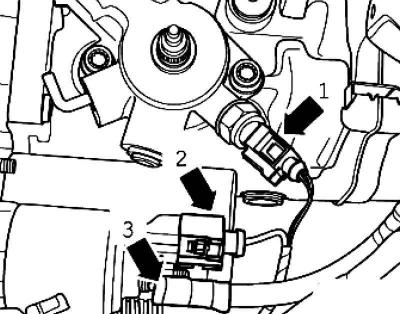

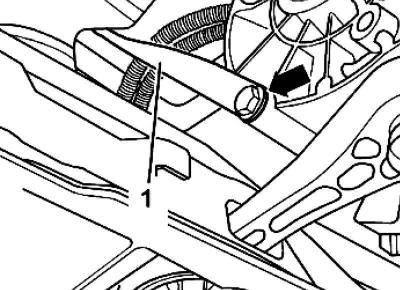

Pic. 3.58. Reversing lamp and starter switch connectors

Disconnect connector 1 from reverse light switch (pic. 3.58).

After that, disconnect connector 2 and line 3 from the starter.

Then remove the top mounting screw on the starter.

Remove the gearbox/engine mounting screws from above.

Disconnect all hoses and wires passing in the area of the eyes for attaching to the engine of the traverse A.

Install the gripping device together with the adapters in front of the hood stop.

Clamp the engine/gearbox assembly lightly with the spindles.

Screw the holder onto the rear three receiving holes of the battery bracket.

To do this, use the M6x80 shoulder bolt or the battery bracket fixing bolt.

Loosen the wheel bolts of the left and right front wheels.

Raise the vehicle.

Remove the front wheels.

Remove the soundproofing.

Remove the lower part of the front left fender locker.

Then be sure to disconnect all hoses from the gearbox.

Pic. 3.59. Protective cap for inner right CV joint

Remove, if present, the protective cap for the inner right CV joint (pic. 3.59).

Detach the exhaust system at the double clamp and unscrew the bracket for the exhaust pipe from the subframe.

Detach the drive shafts from the flanged shafts and secure them in their highest position without damaging the protective coating.

Remove the connecting rods on the left and right from the stabilizer.

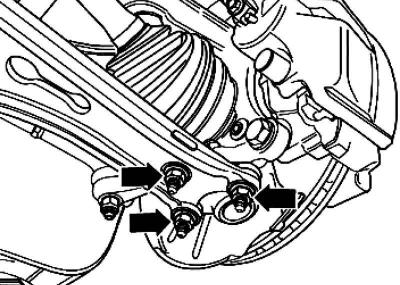

Pic. 3.60. ball joint nuts

Unscrew the nuts of the ball joint to the bearing arm (pic. 3.60).

Remove the lower support of the power unit from the gearbox.

Remove the steering mechanism from the subframe and tie up this mechanism.

Fasten the subframe before removing.

Remove the subframe with pendulum support, stabilizer bar and suspension arms.

Remove the left power unit support hex head screws from the transmission mount.

Tilt the engine/gearbox assembly by lowering crosshead A with the lead screw.

Lower the gearbox by moving the screw grip

Pic. 3.61. Gearbox bracket

Remove the transmission console A (pic. 3.61).

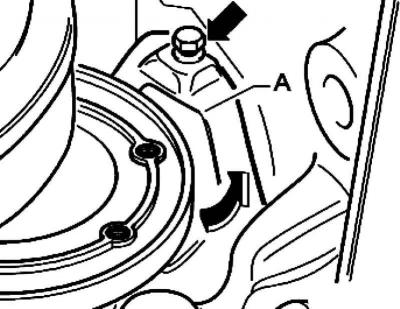

Pic. 3.2. small shield

Small shield A for flywheel behind the right flanged shaft, if present, remove (pic. 3.2).

Pic. 3.62. Fastening of a bar of system of release of OG

Remove the rod 1 of the exhaust system from the gearbox and from the exhaust system (fastening of the rod to the exhaust system is not visible in the figure) (pic. 3.62).

Remove the starter.

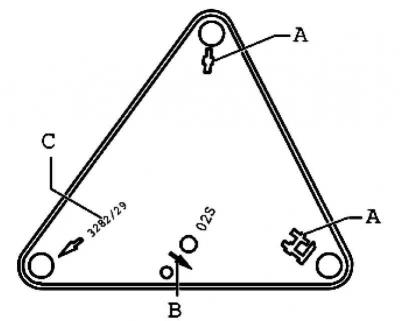

Mounting bracket equipped to remove gearbox «02S» installation template.

Install the mounting bracket on the tilter.

Position the hooks of the mounting bracket according to the position of the mounting template holes.

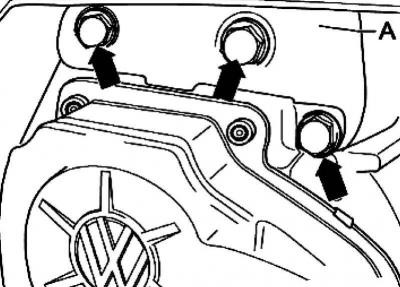

Pic. 3.63. Mounting bracket location

Screw fasteners A and C as shown on the installation template (pic. 3.63).

The turner must be placed under the vehicle, arrow B on the installation template indicates the direction of the vehicle (pic. 3.63).

Align the installation template parallel to the gearbox and secure the fixing support to it.

Then screw the pin into the hole for the mounting screw of the lower support of the power unit on the gearbox.

Remove the bolts securing the gearbox to the engine from below.

Press the gearbox away from the fitted bushings and lower it carefully.

Change the lowering position of the gearbox using the lead screws of the mounting bracket.

Note: Watch all lines when lowering the gearbox.

Visitor comments