Always replace self-locking bolts and nuts.

Check if there are fitted bushings for centering the engine/transmission in the cylinder block, insert them if necessary.

In the absence of fitted bushings, shifting difficulties, clutch problems and, accordingly, noise in the gearbox occur (crackling in drive wheels).

Observe the correct position of the metal gasket on the engine.

Clean input shaft splines and apply a thin coat of clutch disc spline grease.

The clutch disc must move easily on the input shaft.

To install the gearbox «02S» The mounting bracket is equipped with a mounting template.

Position the hooks of the mounting bracket according to the position of the mounting template holes.

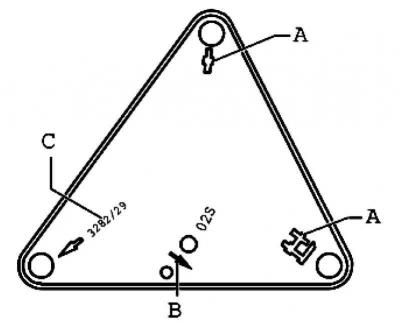

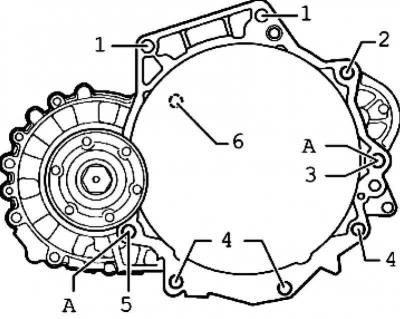

Pic. 3.63. Mounting bracket location

Fasteners A and C (screws) screw in as shown on the installation template (pic. 3.63).

Install the gearbox on the tilter.

Align the setting template parallel to the gearbox.

Screw a pin into the hole for the mounting screw of the lower support of the power unit on the gearbox.

Install the tilter under the vehicle, B on the installation template indicates the direction of the vehicle.

Raise the gearbox towards the engine itself.

Push the engine forward a little (2nd mechanic).

Bring the gearbox into position relative to the engine and install it.

Install the lower gearbox-to-engine bolts and tighten them securely to the correct torque.

After screwing the gearbox to the engine, disconnect the transmission rack from the gearbox.

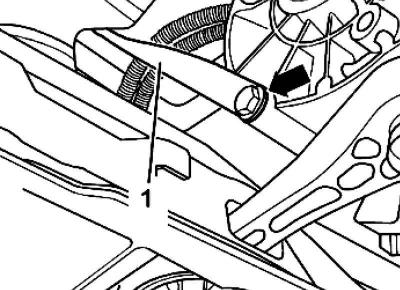

Pic. 3.2. small shield

Small shield A, if equipped, install behind the right flange shaft (pic. 3.2).

Screw the upper bolts of the gearbox to the engine and tighten them tightly with the appropriate torque.

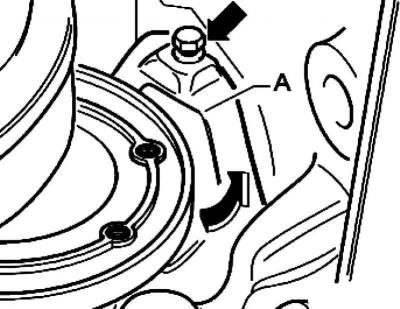

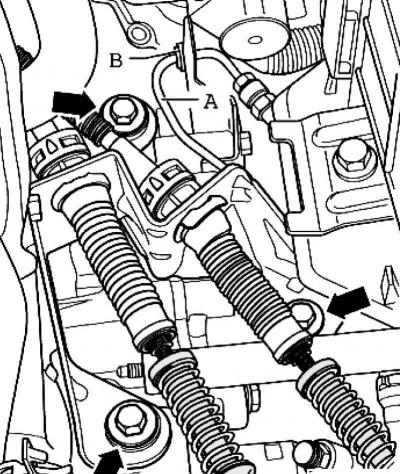

Pic. 3.61. Gearbox bracket

Install support bracket A to the gearbox with new hex head bolts and tighten them to the correct torque (pic. 3.61).

Set the engine/gearbox to the installation position using both spindles of the yoke A.

Install new bolts of the left support of the unit and tighten with a torque.

Attention: Remove the traverse only when all the machine support bolts on the left and right have been tightened to the required tightening torque.

Note: Install the engine/gearbox support free of internal stresses.

Install the drive shafts on the gearbox.

Pic. 3.59. Protective cap for inner right CV joint

Install the protective cap for the inner right CV joint, if equipped (pic. 3.59).

Install the subframe/suspension arm with pendulum support.

Install the steering gear to the subframe.

Establish a pendulum support on a transmission.

Assemble the exhaust system and fit the exhaust bracket to the subframe.

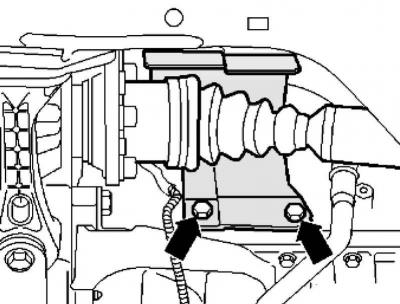

Pic. 3.62. Fastening of a bar of system of release of OG

Install rod 1 of the exhaust system on the gearbox and exhaust system and tighten the bolts to the torque (mounting on the exhaust system is not visible in Figure 3.62).

Install the clutch slave cylinder and tighten the bolts to torque.

Then install the box support A and tighten firmly with the appropriate torque.

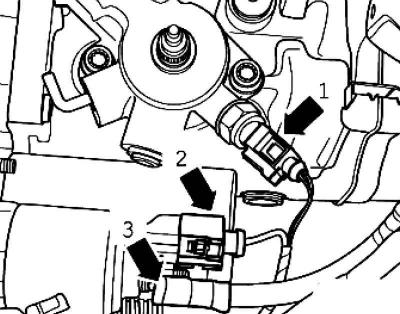

Connect connector 1 to the reversing light switch.

Pic. 3.58. Reversing lamp and starter switch connectors

Install the starter, for which connect connector 2 and screw wire 3 (pic. 3.58).

Attach the ground wire to the upper gearbox-to-engine bolt.

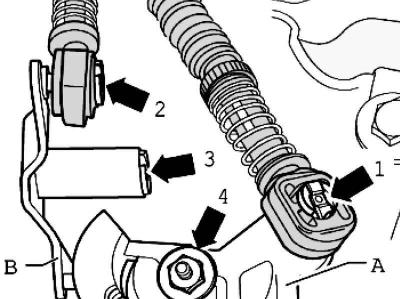

Pic. 3.24. Gearbox Bracket &Tubular Hose

Install bracket B on gearbox (pic. 3.24).

Insert with pressure the pipe-hose line A into the bracket B on the gearbox.

Install the cable stops on the gearbox and tighten the bolts to the specified torque.

Pic. 3.23. Fastening of cables of coupling and the lever of a gear change

Install shift lever A (pic. 3.23).

Tighten nut 4 to the prescribed torque.

Install the intermediate lever B and fix it with a lock washer 3.

Apply a small amount of grease to the pins of shift lever A and intermediate lever B.

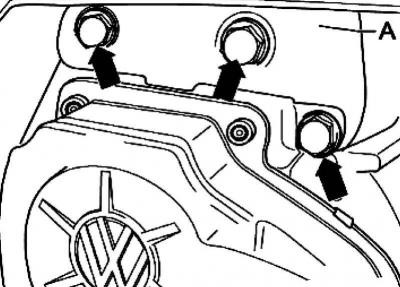

Pic. 3.64. Gearbox to engine

Note: Pos. A Fitted bushings for centering.

Connect shift cable to shift lever 1 and select cable to intermediate lever 2.

Visitor comments