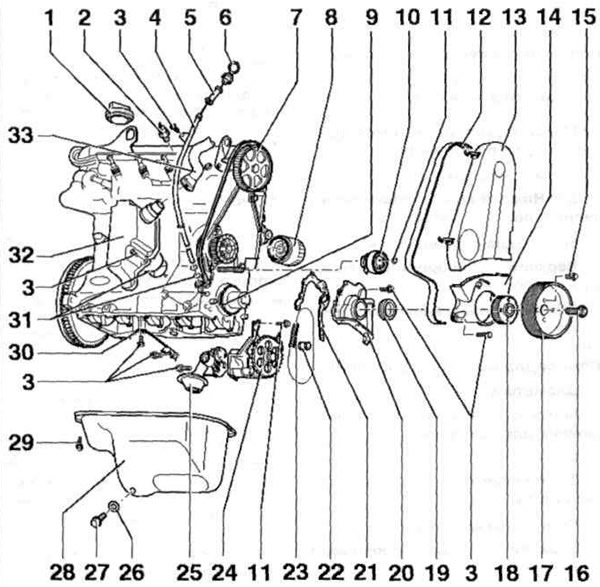

Pic. 3.18. Elements of the lubrication system:

1 - Oil filler cap; 2 - Oil pressure sensor (0.25 bar); 3, 11, 15, 16, 29 - Bolts; 4 - Guide pipe; 5 - Guide sleeve; 6 - Oil level indicator; 7 - Camshaft pulley; 8 - Oil filter; 9 - Toothed pulley of the oil pump drive; 10 - Tensioner; 12 - Toothed timing belt; 13 - Upper part of the timing belt cover; 14 - The lower part of the timing belt casing; 17 - Crankshaft pulley; 18 - Toothed pulley of the crankshaft; 19, 26 - Oil seals; 20 - Sealing flange; 21 - Gasket; 22 - Sealing sleeve; 23 - Chain; 24 - Oil pump; 25 - Oil pump with bypass valve (4.0-5.0 bar); 27 - Drain plug; 28 - Pallet; 30 - Bracket; 31 - O-ring; 32 - Oil separator; 33 - To the air filter.

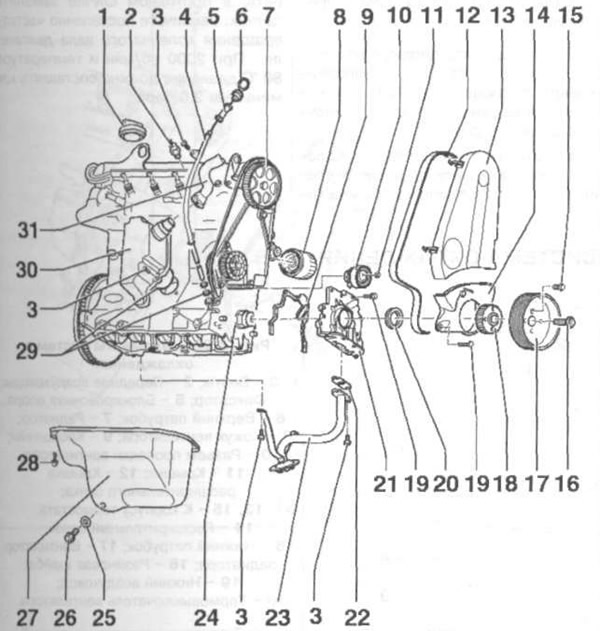

Pic. 3.19. Elements of the lubrication system with a biaxial oil pump:

1 - Oil filler cap; 2 - Pressure sensor (14 bar); 3, 11, 15, 16, 19, 28 - Bolts; 4 - Guide pipe; 5 - Guide sleeve; 6 - Oil level indicator; 7 - Camshaft pulley; 8 - Oil filter; 9, 22 - Gasket; 10 - Tensioner; 12 - Toothed timing belt; 13 - Upper part of the timing belt cover; 14 - The lower part of the timing belt cover; 17 - Crankshaft pulley; 18 - Toothed pulley of the crankshaft; 20, 25 - Oil seals; 21 - Oil pump; 23 - Oil intake; 24 - Drive part; 26 - Drain plug; 27 - Pallet; 29 - O-ring; 30 - Oil separator; 31 - To the air filter.

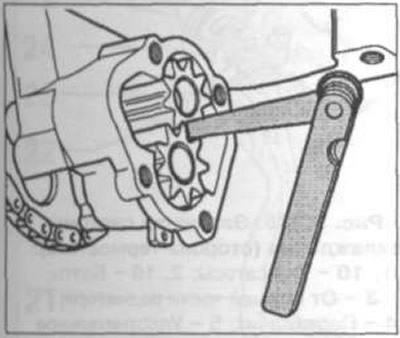

Checking the clearance between the pump gears with a feeler gauge is shown in fig. 3.20 a. New pump clearance: 0.05 mm, allowable wear: 0.20 mm.

Checking the axial clearance of the oil pump is shown in fig. 3.20 b. Permissible wear: 0.15 mm.

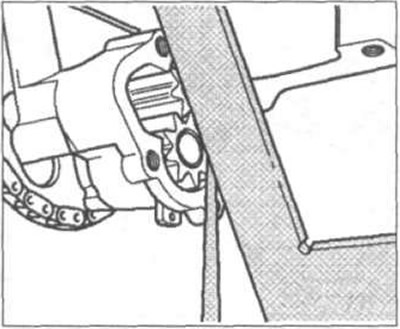

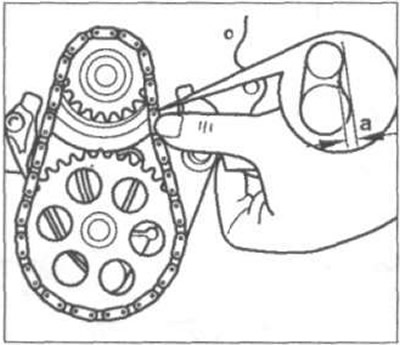

Checking the tension of the oil pump drive chain is shown in fig. 3.20 in. Deflection «A» should be: when checking - 4.0-5.0 mm, when adjusting - 3.5-4.5 mm.

Visitor comments