Brake caliper FS-II/FS-III

Attention: Calipers of different designs are used on the front wheels of the car. Therefore, using the drawings, you should first find out what version of the calipers are installed on your car.

Removing

Attention: The brake pads are covered by a vehicle approval and are factory-fitted for the corresponding vehicle model. Therefore, it is recommended to use only brake pads approved by the vehicle manufacturer.

Mark the direction of tire rotation with an arrow. Loosen wheel bolts. Raise the car in front on the goats and remove the wheels.

Attention: Strictly follow the instructions given in chapter «Removal and installation of a wheel».

Safety note

There is a risk of accident when lifting the vehicle! You must first read the section «Vehicle lifting».

Attention: If the brake pads are to be reinstalled, their location must be marked before removal. It is not allowed to change the pads in places, for example, to change the outer one from the inner one or to rearrange from the right wheel to the left one and vice versa. It is imperative to replace all front brake pads at the same time, even if only one of them has reached the wear limit.

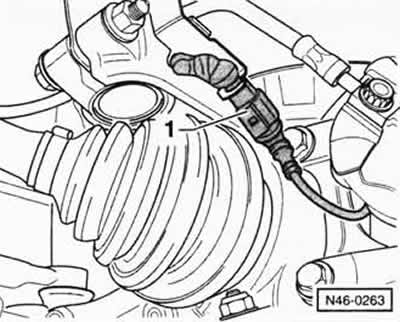

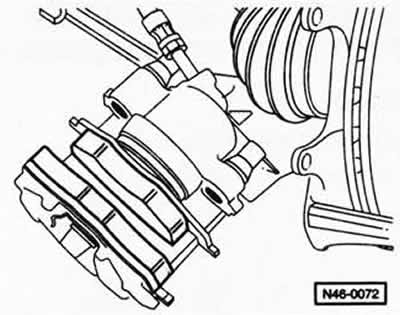

On vehicles with brake lining wear sensor, unplug electrical connector -1-.

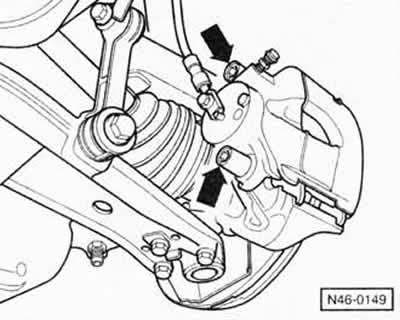

Remove protective caps -arrows- from both guide pins.

Unscrew both guide pins from the brake caliper.

Remove the brake caliper and hang it on a wire to the body. Caution: The brake caliper should not just hang down; The brake hose must not be twisted or stretched.

Remove both brake pads.

Installation

Attention: When the brake pads are removed, do not depress the brake pedal, otherwise the piston will be pushed out of the caliper housing. In this case, the caliper assembly must be removed and the piston inserted at the service station.

Before installing the pads, examine the brake discs to the touch with your fingers for the absence of recesses. Notched discs can be turned (at the service station), if after that they will have sufficient thickness. Be sure to grind both axle discs to the same size.

Measure the thickness of the brake discs, see the relevant chapter below.

Caution: Use only alcohol to clean the brakes. Degrease the guide surfaces and places of the pads in the body shaft with a rag soaked in alcohol. Do not use solutions containing mineral oils and tools with sharp edges. Pay special attention to removing possible adhesive residues from the contact surfaces of the outer brake pads.

Check the brake piston collar for cracks. Replace a damaged cuff immediately, as penetrating dirt will quickly break the tightness of the caliper. In this case, the caliper must be disassembled (at the service station).

Caution: If the brake pads are very worn, check that the piston of the brake cylinder can move freely. To do this, insert a wooden block into the brake caliper and ask an assistant to slowly depress the brake pedal. The piston in the cylinder should be easily squeezed out and pressed back. When checking, the other brake pad, as well as the opposite brake caliper, must be installed in their places. If the piston stroke is heavy, repair the brake caliper (at the service station).

Attention: When the piston is pressed into the cylinder, the brake fluid is squeezed out of the brake cylinder into the compensation reservoir. Monitor the fluid level in the tank and, if necessary, suck out excess fluid with a siphon.

Safety note

For suction, use a bottle that was used to remove air from the hydraulic system, or a plastic bottle that previously only came into contact with brake fluid. Do not use bottles intended for drinking liquids! Brake fluid is poisonous and must never be sucked out by mouth through a hose. Use a siphon for suction. After replacing the brake pads, the level of the brake fluid in the compensation tank should also not be higher than the MAX mark, since the fluid expands when heated. The brake fluid flowing out of the reservoir gets under the brake master cylinder and destroys the paintwork, which leads to corrosion.

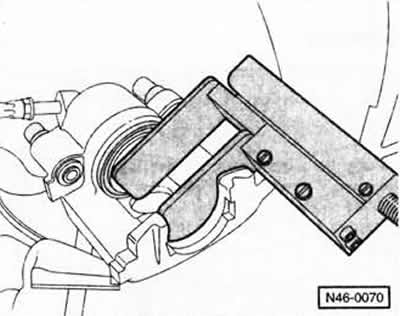

Press the piston of the brake cylinder into the cylinder with a return tool. Note: You can also use a hardwood rod for pressing (hammer handle), however, pay particular attention to ensure that the piston is not distorted and that the piston surfaces and the dust seal are not damaged.

Insert the brake pads into the caliper body and connect to the piston.

FS-II brake caliper:insert brake pads. The brake block with the increased area of a lining is located outside.

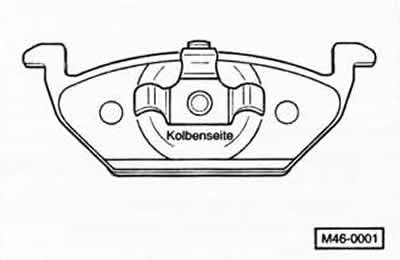

Brake Caliper FS-II/FS-III:insert the brake pads into the caliper housing. Brake shoe with inscription on the back -Kolbenseite- (piston side) inserted into the piston.

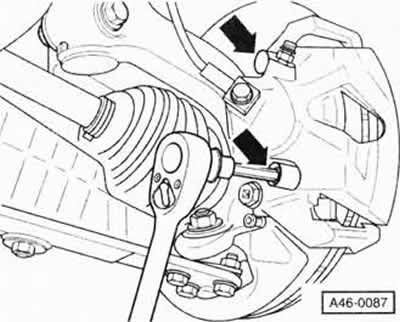

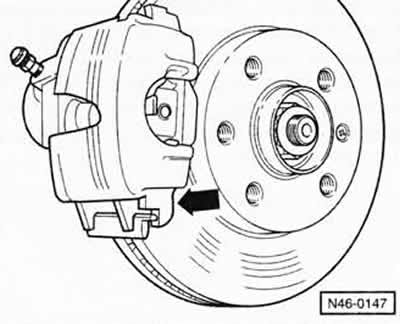

Brake Caliper FS-II/FS-III:mount the caliper housing with brake pads on the steering knuckle. First position caliper housing from below -arrow-. Screw the caliper body to the shoe guide with two guide pins and tighten them to 30 Nm.

Insert protective caps for guide pins.

If present, connect and secure the plug connector for the brake lining wear sensor.

Ensure the same direction of rotation of the tires, bolt the wheels, lower the vehicle and only then tighten the wheel bolts in a crosswise manner to 120 Nm.

Attention: Strictly follow the instructions given in chapter «Removal and installation of a wheel».

Caution: Depress the brake pedal strongly repeatedly with the vehicle stationary until strong resistance is felt. In this way, the brake pads are centered and positioned appropriately for the operating conditions.

Check the brake fluid level in the expansion tank and, if necessary, top up the tank with fluid up to the MAX mark.

Carefully run in new brake pads by repeatedly braking the vehicle from a speed of 80 km/h to 40 km/h by lightly depressing the brake pedal. Allow the brakes to cool down between braking.

Attention: New brake pads must be run in. Until the vehicle has reached a distance of about 200 km, avoid unnecessary braking to a complete stop.

Note: In some areas, worn brake pads must be treated as special waste. Local authorities inform whether they are allowed to be handed over through points of industrial waste, similar to household waste.

Attention, perform a security compliance check:

- Are the brake lines tight?

- Is the brake hose in the holder?

- Are the bleed valves tight?

- Is there enough fluid in the brake system?

- With the engine running, perform a leak test. To do this, act on the brake pedal with a force of 200 to 300 N for about 10 seconds (from 20 to 30 kg). Do not loosen the brake pedal. Check all connections for tightness.

C54-II/POLO brake caliper only

Note: The design of the C54-II brake is basically the same as the Lucas brake for IBIZA.

Attention: Observe the safety regulations, see the contents of this chapter above.

Removing

On vehicles with a brake pad wear sensor, disconnect the sensor connector.

Unscrew the upper and lower hex bolts from the caliper body, remove the caliper body and hang it on a wire to the body.

Caution: The brake caliper should not just hang down; The brake hose must not be twisted or stretched.

Remove the heat shield from the caliper housing.

Remove the inner brake shoe from the shoe guide.

Pull the outer brake shoe out of the retaining spring and pull it forward out of the shoe guide.

Remove the upper and lower retaining springs from the guide pads.

Installation

Insert a new heat shield into the piston.

Insert new brake pad retaining springs.

Tighten new bolts securing brake caliper to shoe guide to 30 Nm.

Connect the plug connector for the brake pad wear sensor.

Visitor comments