Removing

Attention: The brake pads are covered by a vehicle approval and are factory-fitted for the corresponding vehicle model. Therefore, it is recommended to use only brake pads approved by the vehicle manufacturer.

Safety note

There is a risk of accident when lifting the vehicle! You must first read the section «Vehicle lifting».

Mark the direction of tire rotation with an arrow. Loosen wheel bolts. Raise the car from behind on the goats and remove the wheels.

Attention: Strictly follow the instructions given in chapter «Removal and installation of a wheel».

Attention: If the brake pads are to be reinstalled, their location must be marked before removal. It is not allowed to change the pads in places, for example, to change the outer one from the inner one or to rearrange from the right wheel to the left one and vice versa. It is imperative to replace all the brake pads of the bridge at the same time, even if only one of them has reached the wear limit.

Note: Only remove the brake pads on one side of the vehicle so that the brake on the other side can serve as a reference when reassembling.

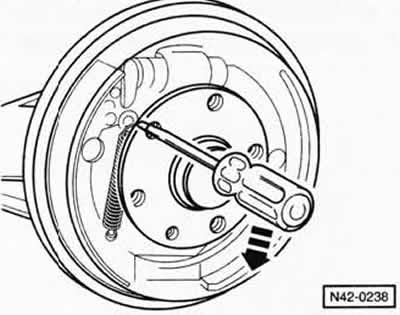

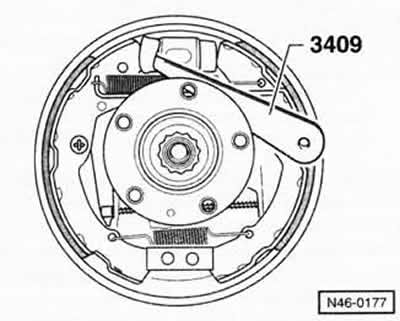

Move the brake pads away from the brake drum. To do this, insert a screwdriver into the threaded hole of the brake drum and press the wedge upwards.

Loosen the cross head screw and remove the brake drum.

Note: Push firmly seated brake drum off the hub with light blows from a plastic hammer, using a conventional puller or using a screwdriver.

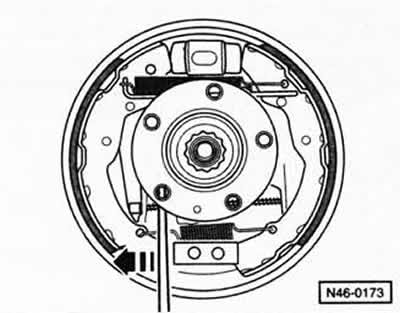

Press spring plate -1- firmly with pliers against pressure spring -2- and turn ¼ turn (90°). Remove spring plate. Remove the second spring plate in the same way. At the same time, hold the spring pin on the reverse side.

Use a screwdriver to press the brake pad in the direction of the arrow.

Unhook the lower retaining spring -5- and remove the brake pads, see figure N46-0145.

Unhook and pull out the handbrake cable.

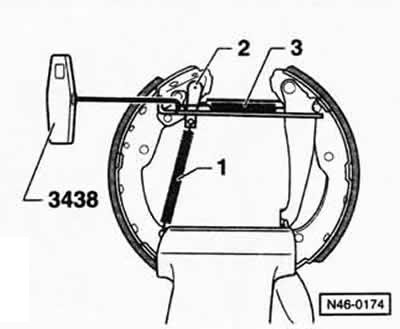

Clamp the brake pads in a vise.

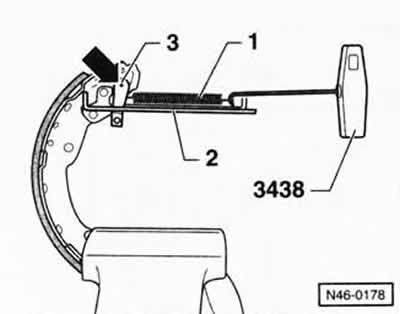

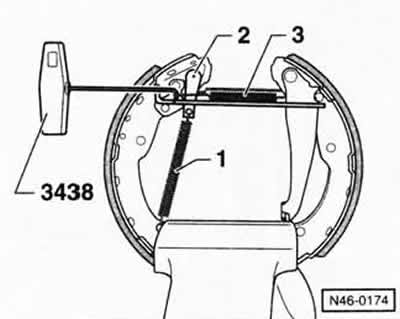

Unhook tension spring -1- from wedge -2-. Using special tool VW-3438 or HAZET 4964-1, unhook retaining spring -3-. You can also use pliers or a hook with a handle.

Caution: Risk of injury!

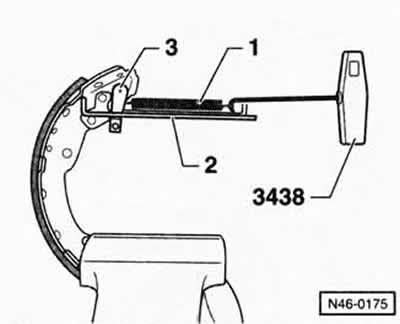

Unhook contact spring -1- using a hook.

Remove expansion bar -2- and wedge -3- from brake shoe.

Installation

Be sure to replace all 4 axle brake pads and use products from the same manufacturer. Brake drum and brake shield should only be cleaned with alcohol. Thoroughly clean parts before reuse.

Caution: Do not inhale brake dust as it can be harmful to health. When replacing the brake pads, do not press the brake pedal, otherwise the piston will be pushed out of the wheel brake cylinder.

Using your hand or a blunt mounting wedge, lift the dust seal at the wheel brake cylinder.

Attention: The piston of the brake cylinder must not be pulled out.

If it is wet under the dust seal, the wheel brake cylinder must be replaced. Put the dust cap back in place.

Use your fingers to check the working surface of the brake drum for notches. Renew notched brake drums, but always replace both brake drums.

Minor irregularities and traces of corrosion on the working surface of the drums should be removed with sandpaper (grit 150).

Measure the inside diameter of the brake drum. If the wear limit is reached, replace the brake drum. In this case, be sure to replace both brake drums of the axle. Nominal dimensions and wear limits of parts are given in chapter «Specifications of the brake system».

Apply VW grease G000650 to the contact surfaces of the return spring and expansion bar.

Hook the contact spring -1- onto the expansion plate -2- using the hook and insert the wedge -3- at the same time.

Attention: The wedge elevation -3- must remain visible during installation.

Insert the brake shoe with the lever for the handbrake cable into the expansion bar.

Attach the tension spring -3- using the hook.

Attach tightening spring -1- to wedge -2-.

Attach the brake shoes to the pistons of the wheel brake cylinder.

Hook the handbrake cable onto the brake shoe lever.

Insert the lower return spring and slide the brake pads onto the lower support.

Install pressure springs and spring plates. To do this, press the spring plate strongly with pliers against the pressure spring and turn it ¼ turn (90°). At the same time, hold the spring pin on the reverse side.

Install brake drum and secure with Phillips head screw.

With the hand brake released, fully depress the brake pedal. In this way, the brake pads are centered and positioned appropriately for the operating conditions.

Adjust the handbrake see relevant chapter.

Ensure the same direction of rotation of the tires, bolt the wheels, lower the vehicle and only then tighten the wheel bolts in a crosswise manner to 120 Nm.

Attention: Strictly follow the instructions given in chapter «Removal and installation of a wheel».

Check the brake fluid level in the expansion tank and, if necessary, top up the tank with fluid up to the MAX mark.

Carefully run in new brake pads by repeatedly braking the vehicle from a speed of 80 km/h to 40 km/h by lightly depressing the brake pedal. Allow the brakes to cool down between braking.

Attention: New brake pads must be run in. Until the vehicle has reached a distance of about 200 km, avoid unnecessary braking to a complete stop.

Attention, perform a security compliance check:

- Are the brake lines tight?

- Is the brake hose in the holder?

- Are the bleed valves tight?

- Is there enough fluid in the brake system?

- With the engine running, perform a leak test. To do this, act on the brake pedal with a force of 200 to 300 N for about 10 seconds (from 20 to 30 kg). Do not loosen the brake pedal. Check all connections for tightness.

Visitor comments