Removing

Mark the direction of tire rotation with an arrow. Loosen wheel bolts. Raise the car so that the front axle is unloaded.

Using a 19 mm hexagon socket wrench, unscrew the nut with stamped rim -10- at the shank of the universal joint; or use a 36 mm Allen socket socket to loosen the 12-point nut -11-, see figure S40-0204.

Remove the wheel.

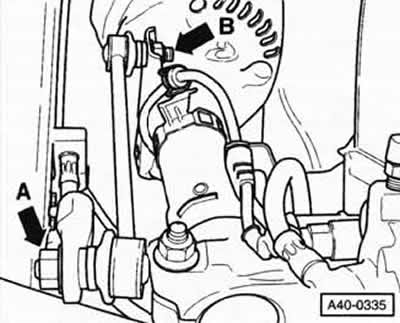

Remove upper nut -arrow B- securing connecting rod to suspension strut. Arrow A - bottom nut for fastening the connecting rod.

Disconnect the speed sensor electrical wire from the suspension strut.

Remove tie rod end.

Raise the tie rod and tie it to the body.

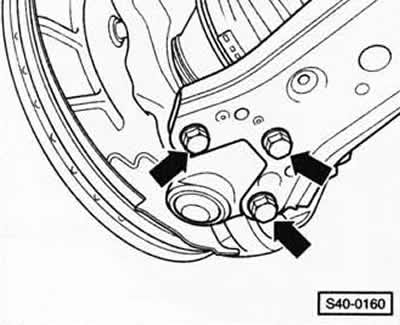

Mark the mounting position of the bolts -arrows- in relation to the control arm with a scriber and remove the bolts.

Remove the steering knuckle together with the ball joint from the transverse arm.

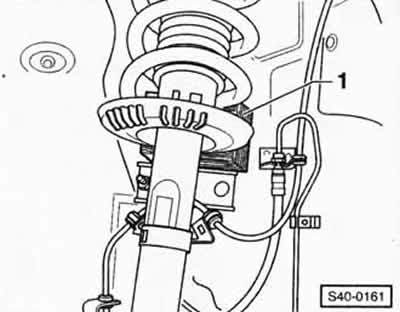

Swing the spring strut outward and support it with, for example, a block of wood -1-.

Pull the cardan shaft out of the steering knuckle and, lifting it, tie it to the body, see chapter «Removal and installation of cardan shaft».

Attention: The cardan shaft must not sag downwards.

Bolt ball joint back to transverse link. To do this, use the unscrewed bolts and the removed sheet metal folding plate.

Place a suitable jack under the steering knuckle.

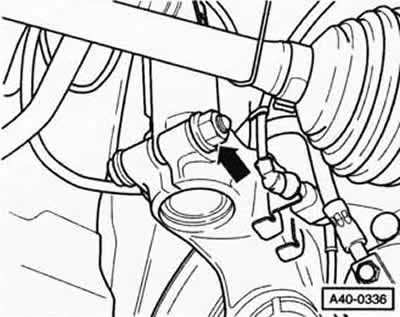

Unscrew nut -arrow- securing suspension strut to steering knuckle and remove bolt.

Note: When installing, replace the bolt with a new one.

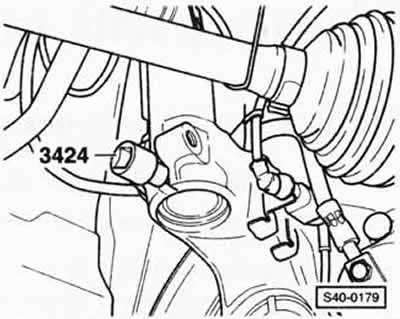

Insert a suitable expansion tool, eg VW-3424, into the slot in the knuckle, turn the ratchet 90°. Leave the expanding tool in the slot and remove the ratchet.

Press the brake disc in the direction of the suspension strut. At the same time, the shock absorber tube may receive some distortion relative to the axis of the hole in the steering knuckle.

Remove the steering knuckle from the shock absorber tube downwards, while lowering the jack until the shock absorber tube hangs freely.

Tie the knuckle firmly to the front axle beam.

Remove jack.

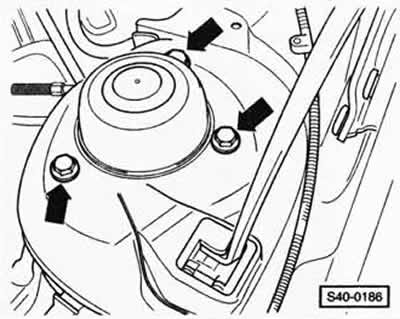

Unscrew securing bolts -arrows- of suspension strut to wheel housing support.

Remove shock absorber.

Installation

Insert suspension strut and fasten with new bolts to the support cup of the wheel arch.

Attention: When doing this, first install the bolts from the inside of the vehicle. Tighten the bolts to a torque of 15 Nm, then turn them 90°in the direction of tightening with a locked wrench.

Place a jack under the steering knuckle.

Insert the suspension strut into the steering knuckle.

Untie the steering knuckle from the front axle beam.

Raise the steering knuckle with a jack until you can insert a new bolt securing the shock absorber to the steering knuckle.

Caution: Never press the ball joint with a jack.

When lifting, press the brake disc against the suspension strut. Make sure that the shock absorber tube in the steering knuckle bore is not twisted.

Pull out the spreading tool.

Screw a new nut onto the new suspension strut to steering knuckle bolt and tighten.

Tighten the fastening nut to a torque of 60 Nm, then tighten it by 90°in the direction of tightening.

Unscrew the 3 bolts securing the ball joint and disconnect the steering knuckle with the ball joint from the transverse arm.

Insert the propeller shaft into the wheel hub. Make sure that the universal joint gaiter is not damaged or twisted.

Bolt the ball joint to the control arm using new bolts and a new flare washer. Align the ball joint so that the fastening bolts take up the positions marked before removal. Tighten the bolts to a torque of 20 Nm, then tighten them by 90°in the direction of tightening.

Install the tie rod end.

Attach the electrical wire of the speed sensor to the suspension strut.

Tighten connecting rod to suspension strut to 40 Nm.

Note: Remove any traces of corrosion, grease and sealant residues from the threads and splines of the outer universal joint shaft and from the splines of the wheel hub.

Apply Loctite 601 to the splines of the universal joint shank.

Apply Polyharnstoff G052142A2 grease to the threads of the universal joint shank.

When installing a stamped rim nut: Always use a new nut and tighten to 30 Nm.

When installing a 12-point nut: Do not lubricate the threads on the end of the shank of the universal joint. Be sure to use a new nut and tighten it to a torque of 50 Nm, then tighten it by 45°in the direction of tightening.

Keeping the tire in the same direction of rotation, bolt the wheel and lower the vehicle. Only then tighten the wheel bolts crosswise to 120 Nm.

Attention: Strictly follow the instructions given in chapter «Removal and installation of a wheel».

Visitor comments