- Prolonged oscillation of the body during uneven roads.

- Shaking of the body during successive bumps in the road.

- The bouncing of the wheels is also on a flat road.

- Vehicle failure during braking (may also have other causes).

- Danger when turning due to insufficient longitudinal stability, vehicle skidding.

- Abnormal tire wear with uneven tread wear.

- Rumbling noises while driving. Of course, often these noises also occur for other reasons, for example, as a result of loosening of the bolts and nuts of the undercarriage, a defect in the wheel bearing, the constant velocity joint. The shock absorber must therefore always be checked before replacement, if necessary on a shock absorber test bench.

The shock absorber can be checked by hand. However, an accurate test of the ability of the shock absorber installed on the vehicle to receive the load is possible only with the help of a diagnostic tool, and the shock absorber removed from the vehicle - on the shock absorber test stand.

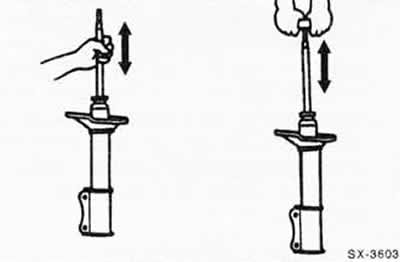

Hand checking

Remove shock absorber.

Holding the shock absorber in the mounting position, stretch it, and then compress it. During the entire stroke, the shock absorber piston rod should move evenly and heavily and without jerks.

Check the piston rod for surface damage, bending and perfect running in the guide bush.

Inspect the rubber support in the housing lug. The rubber mounts must be firmly seated in the housing and must not be cracked or damaged. Defective bearings can cause rattling noises when riding.

With a gas-filled shock absorber, the piston rod, with sufficient gas pressure, returns to its original position on its own. If this is not the case, then it is not necessary to replace the shock absorber. The shock absorber remains operational until an increase in oil loss occurs. The damping effect of the shock absorber is fully maintained even in the absence of gas pressure. However, the noise quality of the shock absorber may be degraded.

When working flawlessly, slight traces of oil on the surface of the shock absorber are not grounds for replacing it. The hard and fast rule is: If the oil stain is obvious and extends no further than from the piston rod seal to the lower spring cup, then the shock absorber is considered to be in order. The prerequisite for this is that the oil stain is dull, dull or, due to dust, dried up. The slight oil escaping is even an advantage, as it keeps the O-ring lubricated and therefore lasts longer.

If there is a significant loss of oil, the shock absorber should be replaced.

Shock Absorber Disposal

To dispose of the shock absorber, you must first drain the hydraulic oil from it. The empty shock absorber can then be handed over as normal scrap metal.

Caution: Hydraulic oil is a problematic material and should never be simply dumped on the ground or disposed of with normal household waste. District and city authorities should inform where the nearest collection points for special waste are located.

Safety note

The gas pressure in the new shock absorber reaches 25 bar. Therefore, when opening the shock absorber, it is necessary to shield the workplace and be sure to wear safety glasses.

Removing the contents of the internal cavities of the shock absorber can be done by drilling or sawing through its outer walls in the places indicated below.

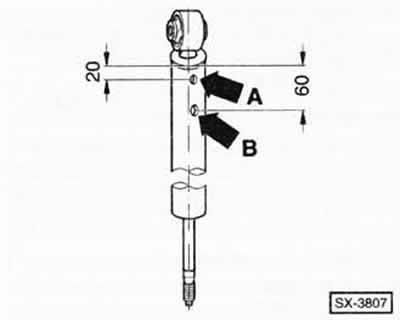

Drilling the walls of the shock absorber

Clamp the removed shock absorber in a vise vertically with the piston rod down.

Stepping back from the bottom of the shock absorber about 20 mm -A-, drill a hole in the outer wall with a diameter of 3 mm.

Attention: After drilling the outer wall, gas escapes to the outside. Cover the opening with a rag during gas removal. Then continue drilling until the inner tube is drilled (approx. 25 mm).

Stepping back about 60 mm from the bottom -B-, drill another hole in the shock absorber with a diameter of 6 mm, passing through the inner pipe.

By moving the shock absorber piston in both directions to the full stroke, squeeze out the hydraulic oil into the substituted container.

Let the oil drain completely from the shock absorber.

Take the hydraulic oil to a special waste collection point.

Take the empty shock absorber to a scrap metal collection point.

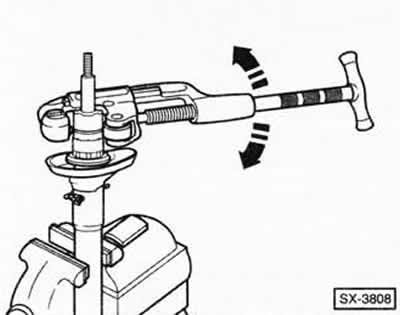

Cutting the shock absorber

Clamp the shock absorber in a vise.

Attach a pipe cutter, eg Stahlwille Express 150/3, and separate the outer pipe.

Caution: Gas-filled shock absorbers release gas, wear protective goggles.

Pull the piston rod up, while holding the inner tube with a pipe wrench and pushing down so that it remains in the outer tube when the piston rod is slowly pulled up.

Remove the piston rod from the inner tube.

Hold the shock absorber over a container and drain the oil completely until it stops escaping.

Take the oil to a special waste collection point.

Empty shock absorber to be scrapped.

Visitor comments