Removing

Note: The light alloy rims are protected against corrosion with a clear lacquer. When changing wheels, take care not to damage the protective layer, otherwise the protective coating must be restored.

Before removing the wheel, mark the direction of rotation of the tire by drawing an arrow on its sidewall with chalk.

Take measures to prevent the vehicle from rolling. To do this, apply the handbrake and engage 1st gear or reverse gear. On a vehicle with an automatic transmission, move the operating mode selector to position P. In addition, place a wedge under the diagonal wheel. Always place the wedge on the side into which the vehicle can roll when it is raised.

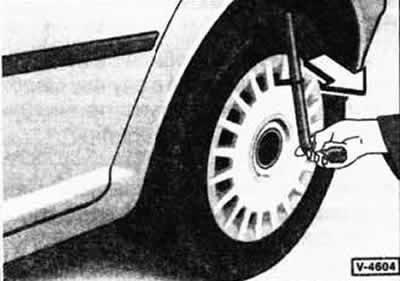

Wheel with cap for the entire rim: hook the cap through the recess with a hook from the on-board tool kit and press the cap off the wheel rim.

Wheel with a cap in the center of the rim: remove the cap with a wire hook.

Wheel with protective caps of the mounting bolts, remove the protective caps with a wire hook.

Loosen wheel bolts ½ turn, do not unscrew.

Attention: In this case, the car must stand on the platform with all wheels, the gear must be engaged and the handbrake must be applied. Do not use a torque wrench to loosen the bolts.

Safety note

There is a risk of accident when lifting the vehicle! You must first read the section «Vehicle lifting».

Automobile jack up so that the wheel does not touch the ground.

Remove wheel bolts and remove wheel.

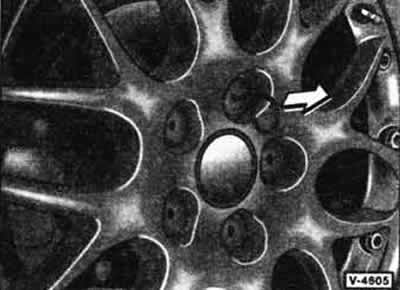

Note: To loosen wheel bolts with wheel theft protection, an adapter is required, which is usually included in the on-board tool kit. Before loosening the bolts, remove the protective caps from them. Take the adapter from the tool kit and insert it into the wheel bolt as far as it will go. Loosen the bolt with the wheel bolt wrench. The adapter code number is stamped on its end. This number should be written down and carefully stored in case of restoration of the adapter if it is lost.

Installation

To protect against deep corrosion, the landing site of the disk wheel on the hub, both in front and behind, must be lightly lubricated with grease for rolling bearings after each removal of the corresponding wheel.

Clean dirty bolts and threads. Do not lubricate the threads of the wheel bolts.

Attention: Rusty wheel bolts that are difficult to screw in must be replaced immediately. Until this is done, a moderate speed should be observed while traveling.

Attach the wheel to the hub in accordance with the mark on the direction of rotation made before removal.

Screw in wheel bolts and lightly tighten crosswise to 50 Nm.

Lower the car and remove the jack.

Tighten the wheel bolts crosswise in several steps. A torque wrench must always be used to tighten the wheel bolts. This ensures that the wheel bolts are evenly and firmly tightened. The tightening torque for the wheel bolts for both steel and light alloy rims is 120 Nm.

Caution: If the wheel bolts have been tightened without using a torque wrench, the tightening torque must be checked immediately by a workshop. If the wheel bolts are tightened one-sidedly or unevenly, increased stresses can occur in the wheel and/or wheel hub.

A wheel with a cap for the entire rim: press the cap against the rim, first in the area where the rubberized tire valve is located, and then fix it around the entire perimeter. If necessary, press the cap against the rim with palm strokes.

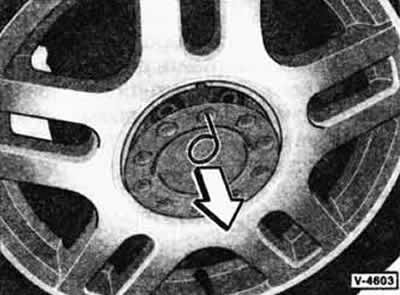

Wheel with a cap in the center of the rim: attach the cap and fix it. When doing this, make sure that the protrusion on the cap fits into the recess on the rim, see figure V-4603.

Wheel with protective caps for the mounting bolts: put the protective caps on the bolt heads.

Attention: Rims and wheel bolts are matched. When replacing light alloy rims with steel rims, for example when changing to winter tires with steel rims, the appropriate wheel bolts of the appropriate length and shape must also be used. The reliability of fastening the wheels and the operation of the brake system depend on this.

After changing the tires, always check and, if necessary, adjust the inflation pressure.

Visitor comments