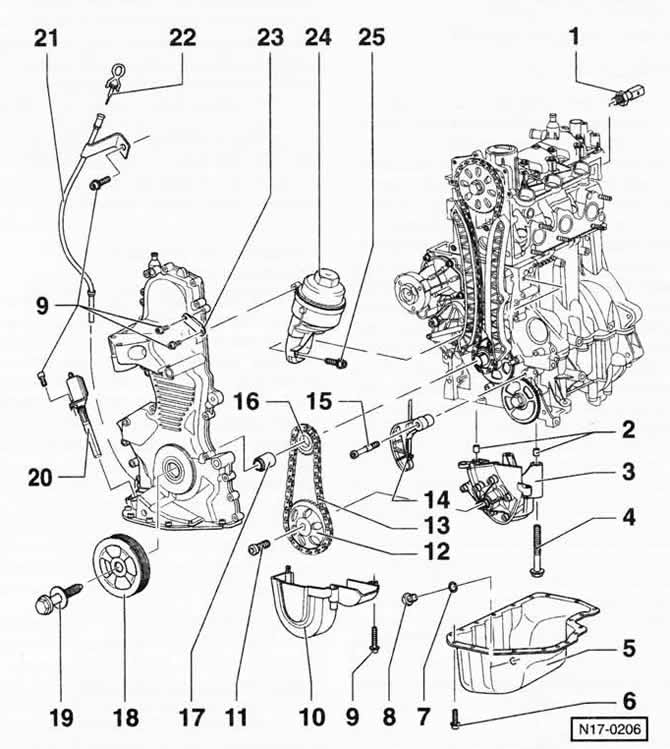

1.2L petrol engine

1 - hydraulic switch, 0.3-0.7 bar, 25 Nm

2 - guide bushings

3 - oil pump

Replace only as an assembly.

4 - bolt, 25 Nm

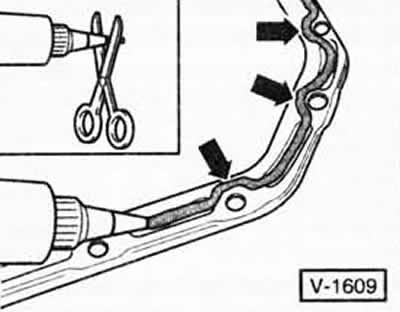

5 - oil pan

Before installation, the sealing surfaces must be thoroughly cleaned of oil and grease. Remove the remaining sealant with a rotating plastic brush, install the oil pan on the silicone sealant WV-D 17B 404 A2.

Apply sealant with a strip width of 2...3 mm.

Attention: The width of the strip must not exceed the specified size, otherwise excess sealant may enter the oil pan and contaminate the suction pipe mesh. Place bead of sealant in the area of the holes for the fastening bolts on the inside -arrows-.

After applying the sealant, install the drip tray within 5 minutes at the latest. After installation, allow the sealant to cure for approximately 30 minutes before adding engine oil. The installation of the oil pan will be facilitated if the M6 studs are screwed into the engine block as guides in two places.

6 - bolt, 15 Nm

7 - sealing ring

Always replace.

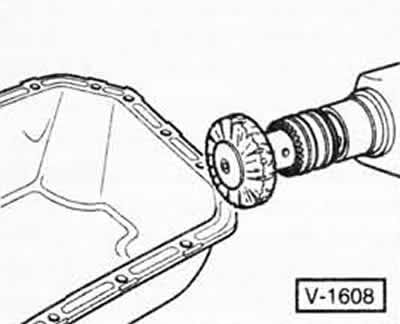

8 - oil drain plug, 30 Nm

Always replace. With non-removable sealing ring.

9 - bolt, 8 Nm

10 - cover

11 — bolt, 20 Nm + 90° (¼ turn) in tightening direction

12 - asterisk

For roller chain. After installation, adjust the valve timing (at the service station).

13 - roller chain

Before removing, mark the direction of travel.

14 - chain tensioner with strap

15 - bolt, 15 Nm

16 - asterisk

For roller chain.

17 - bearing sleeve

18 — a belt pulley of a cranked shaft

19 — bolt, 90 Nm + 90° (¼ turn) in tightening direction

Always replace. Lubricate before installation. When loosening and tightening, hold the belt pulley with a standard holder.

20 - engine oil level / temperature sensor

21 - guide tube

22 - oil level indicator (probe)

The engine oil level should not be above the MAX mark.

23 - holder

24 - oil filter

25 - bolt, 25 Nm

Note: The illustration shows an AWY engine with two valves per cylinder.

Visitor comments