1.4 l FSI petrol engine: Front left on cylinder head, see position -14- on drawing N15-0650.

Diesel engine: on the oil filter bracket.

Examination

Check and, if necessary, correct the engine oil level.

Warm up the engine to operating temperature and let it idle until the cooling system radiator fan turns on and off again.

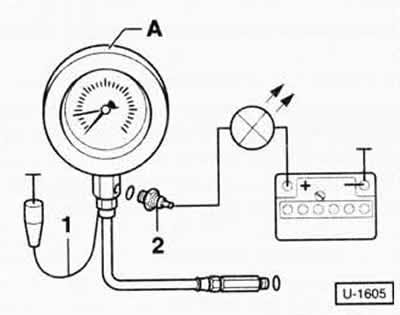

Unscrew hydraulic switch -2- and screw it into measuring device -A-.

Screw the oil pressure gauge into the hole for the hydraulic switch.

Connect the brown wire -1- of the measuring device to ground (-).

Connect a test lamp on semiconductor diodes to the positive pole (+) battery and hydraulic switch.

The LED should not light up.

If the LED lights up, replace the hydraulic switch.

If the LED does not light up:

Start the engine.

Attention: When starting the engine, observe the gauge and the indicator lamp LED, as the opening pressure of the hydraulic switch may already be exceeded when the engine is started.

Slowly increase engine speed. When the set pressure range is reached, the LED must light up, otherwise the hydraulic switch must be replaced.

Oil pressure check

Increase engine speed to 20001/min. The engine oil pressure must be at least 2.0 bar.

If the prescribed pressure value is not reached:

Check the engine for mechanical damage, such as damage to the crankshaft bearings (at the service station).

If necessary, replace the oil filter bracket together with the pressure reducing valve or the oil pump respectively.

Caution: At higher engine speeds, the engine oil pressure must not exceed 7.0 bar (1.4 l diesel engine: 5.8 bar). Otherwise, check the oil channels. If necessary, replace the oil filter bracket together with the pressure reducing valve.

Additional information: 1.4l FSI petrol engine: oil filter cap with 2.5 bar bypass valve.

1.4 l TDI engine: oil pump with 11.5 bar pressure relief valve.

1.9 l SDI/TDI engine: oil pump with 12 bar pressure reducing valve.

Visitor comments