The cylinder block and cylinder head are die-cast aluminum alloy. In this case, the cylinder block has a connector along the axis of the crankshaft with the crankcase, and sealing in the connector plane is provided using a liquid sealant. The crankshaft is mounted in four main bearings with a socket in the same plane. A balancing mechanism is located in the crankcase of the engine. It is designed to reduce vibrations that occur in a 3-cylinder engine and ensure smooth engine operation. The balancing mechanism is driven through two gears, one of which is located on the crankshaft. The balancer shaft rotates at the same frequency as the crankshaft, but in the opposite direction. The cylinder head is bolted to the cylinder block.

An engine with two valves per cylinder (40 kW/55 hp) The camshaft is mounted in bearings, one half of which is in the cylinder head cover and the other half in the cylinder head.

Engine with four valves per cylinder (47 kW/64 hp) the intake and exhaust camshafts are located in their own crankcase. 4 bearing caps are bolted to the camshaft housing.

The valves are driven by camshafts through pressure levers with rollers, with one end of each lever resting on a hydraulic lash compensator in the valve drive. Distribution drive (s) shaft (shafts) driven from the crankshaft by a maintenance-free chain.

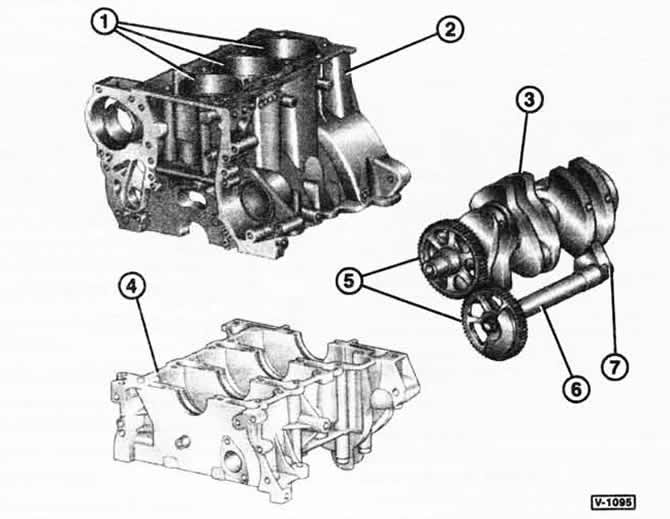

1 - cylinder bushings made of gray cast iron

2 - engine block

3 - crankshaft

4 - engine crankcase

5 - gears

6 - shaft of the balancing mechanism

7 - counterweight of the balancing mechanism

Visitor comments