Removing

Disassemble the engine (see above stripped "Engine disassembly and assembly").

Pull out the camshaft.

Take out the crankshaft, bearings and remove the 1st bearing from the flywheel side. Make sure that the bearings do not fall off when pulling out the crankshaft. Tag them.

Disassembly

Attach the crankshaft to the bearings.

Remove the V-belt pulley key and remove the 4th bearing together with the slinger disc.

Using special pliers, remove the circlip of the ignition distributor drive gear.

Press out the ignition distributor drive gear, the adjusting ring and the timing gear drive gear from the crankshaft. Remove dowels.

Remove the 3rd bearing.

Remove rods.

Clean the crankshaft and blow out the oil passages with compressed air. Lubricate all main and connecting rod journals with oil so that they do not corrode.

Check crankshaft for cracks, regrind or replace if necessary.

Check the holes of the ignition distributor drive gear and the timing gear drive gear for scoring, check the ring gear contact patch.

Check the seating of the dowel pins.

Assembly

Wash the crankshaft with gasoline, blow out the oil channels with compressed air.

Lubricate the 3rd bearing with oil and slide it onto the shaft.

Install keys for both drive gears.

Heat both drive gears in oil bath to approximately 80°C.

Press the heated timing gear onto the shaft with the chamfer facing the 3rd bearing.

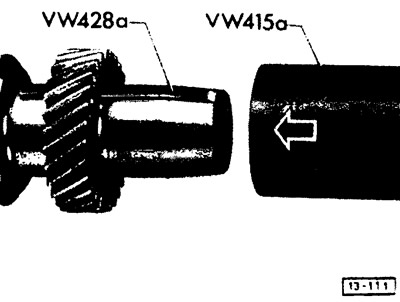

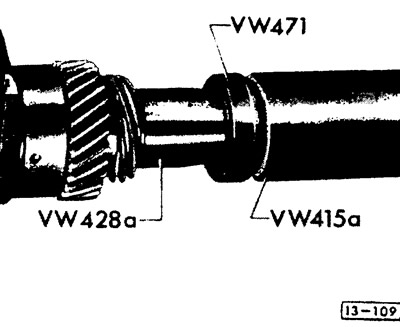

A bushing and a guide wedge are used to install the timing gear and the ignition distributor drive gear. The latter serves to ensure that during installation, give the groove in the drive gear the correct direction in relation to the key.

Put on the adjusting ring.

Press on (also with bushing and guide wedge) heated drive gear of the ignition distributor and, after cooling, check the tightness of its fit.

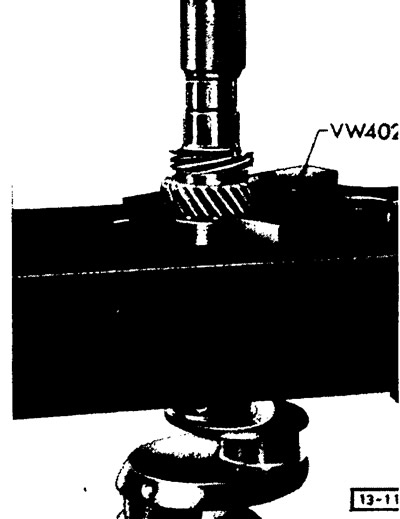

Install retaining ring. To do this, close the 4th shaft journal with a tapered guide sleeve so as not to damage its bearing surface.

Lubricate with oil and install the 4th bearing. The annular groove in it should be directed towards the oil slinger disc.

Install the V-belt pulley key.

Install rods.

Installation

Attention! The oil outlet holes in the shaft journals and bearings must not have sharp edges.

If there are foreign metal inclusions on the working surface of the bearings, they must be carefully removed with a file, without damaging the bearing.

Attention! New bearings do not need to be machined.

Check the fit of the dowel pins in the bearing bores.

Install the 2nd bearing in the hole.

Lubricate the 1st bearing with oil and install it on the shaft so that its holes for the dowel pins are directed towards the flywheel.

Install the crankshaft, making sure that all the dowel pins are correctly inserted into the bearing holes.

When installing the crankshaft, you must take into account the marks of its installation position in relation to the camshaft.

Collect crankcase.

Visitor comments