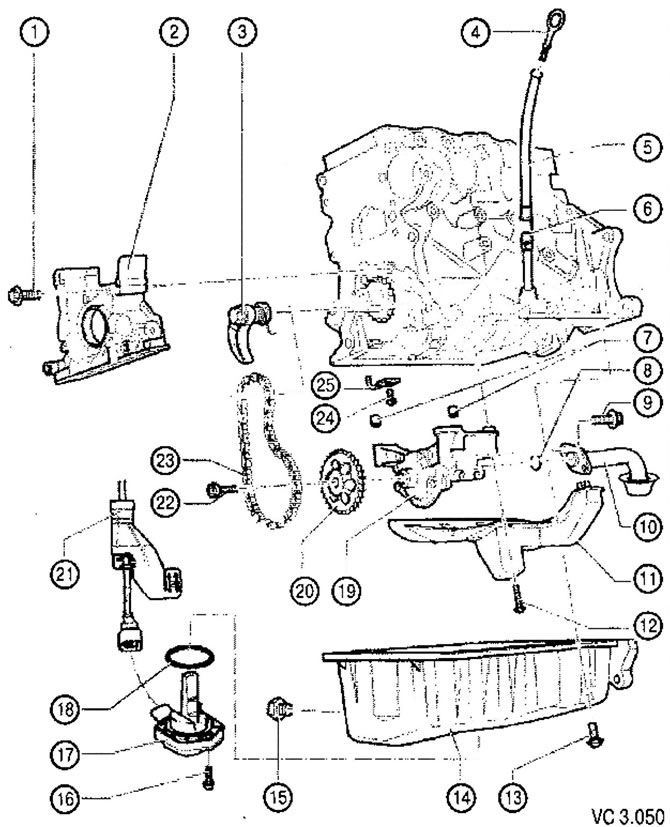

List of components and parts of the lubrication system with technological notes on repair to Figure VC3.050:

1. Screw of fastening of a forward cover of the block of cylinders: 15 Nm.

2. Front cylinder block cover with crankshaft oil seal:

- mounted on centering bushings;

- when installing, apply sealant;

- do not additionally lubricate the working edge of the stuffing box;

- before installation, remove any remaining oil on the crankshaft journal with a clean cloth,

3. Chain tensioner with shoe: 15 Nm:

- compress the spring before installing.

4. Oil dipstick.

5. Upper part of the dipstick tube.

V. The bottom of the oil dipstick tube.

7. Centering sleeves.

8. O-ring:

- when assembling, replace with a new one.

9. Oil receiver mounting screw: 15 Nm.

10. Oil receiver:

- if necessary, clean the grid.

11. Reflector.

12. Oil pump mounting screw: 15 Nm.

13. Oil pan fixing screw: 15 Nm.

14. Oil pan:

- before installation, clean the contact surfaces;

- apply sealant during installation.

15. Oil drain plug: 30 Nm:

- when assembling, replace with a new one.

16. Screw for fastening the oil level and temperature sensor: 10 Nm.

17. Oil level and temperature sensor (G266):

- black connector, 3-pin.

18. O-ring:

- when assembling, replace with a new one.

19. Oil pump with pressure reducing valve 1.2 MPa (12 bar):

- check availability before installation

- centering bushings that determine the relative position of the oil pump and the cylinder block;

- replace the pump if grooves are formed on the working surfaces and gear wheels.

20. Oil pump drive sprocket.

21. Bracket for the wiring harness of the oil level and temperature sensor

22. Screw for fastening the driven sprocket of the oil pump drive: 20 Nm and tighten 1/4 turn (90°):

- when assembling, replace with a new one.

23. Oil pump drive chain.

24. Piston oil nozzle mounting screw: 25 Nm:

- install without sealant.

25. Nozzle for oil cooling of the piston.

Visitor comments