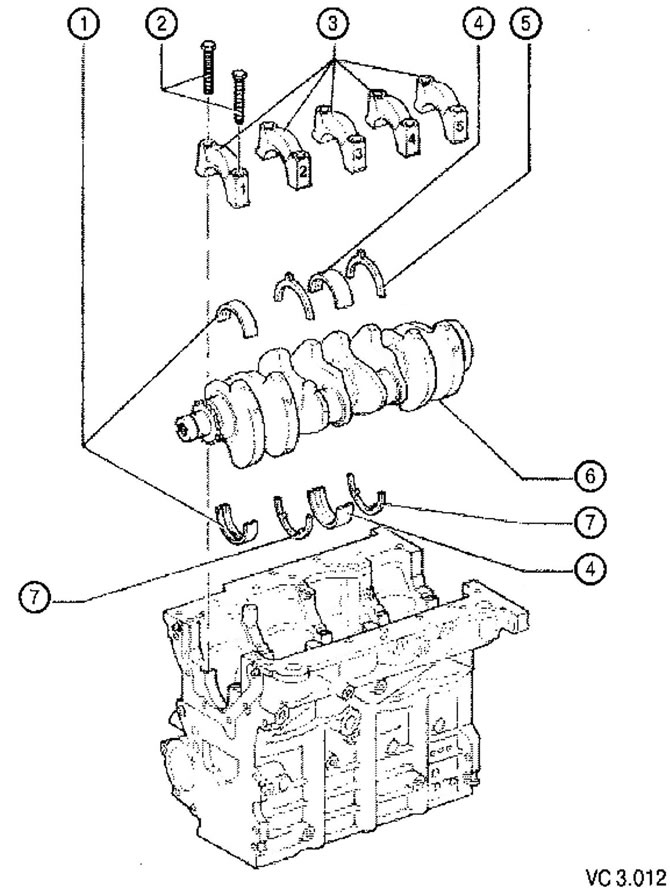

List of KShM parts with technological notes on repair to drawing VC3.012:

1. Inserts 1, 2, 4 and 5:

- without lubrication grooves are installed in the main bearing caps;

- with an oil groove are installed in the cylinder block;

- do not interchange previously used liners (mark when removing).

2. Main bearing cap screws: 65 Nm and tighten 1/4 turn (90°):

- when assembling, replace with new ones;

- to measure the radial clearance, tighten to 65 Nm, short of 90°.

3. Bearing cap:

- bearing cover 1: counting from the timing drive;

- bearing cover 3: with grooves for thrust half rings;

- the retaining tabs of the liners installed in the cylinder block and in the main bearing caps must be installed against each other.

4. Insert 3:

- without lubrication groove is installed in the main bearing caps;

- with oil groove installed in the cylinder block,

5. Thrust half ring installed in the main bearing cap 3:

- when installing, make sure that it is securely fixed in the seat.

6. Crankshaft:

- axial run:

- new shaft: 0.07...0.17 mm,

- wear limit: 0.37 mm;

- measure the radial clearance using a plastic Plastigage gauge:

- new shaft: 0.03...0.08 mm,

- wear limit: 0.17 mm;

- when measuring the radial clearance, do not rotate the crankshaft.

7. Thrust half ring installed in the cylinder block (main bearing 3).

Crankshaft Dimensions

| Nominal size | Main journal diameter | Crankpin diameter |

| Size value | 54,00 (0,022; -0,042) mm | 47,80 (-0,022; -0,042) mm |

Visitor comments