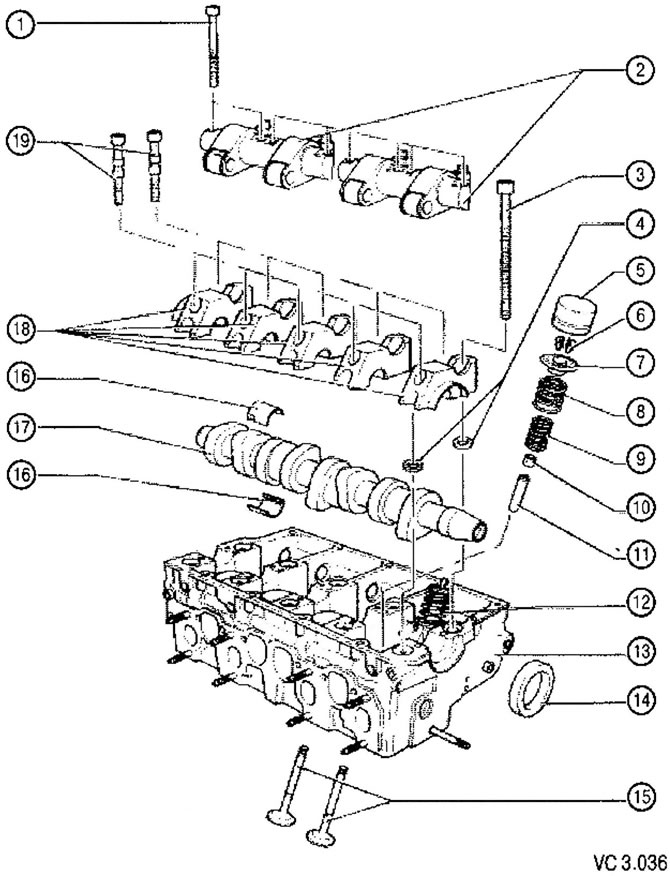

List of assemblies and parts of the valve mechanism with technological notes on repair to drawing VC3.036:

1. Rocker shaft mounting screw: 20 Nm and tighten 1/4 turn (90°):

- when assembling, replace with a new one;

- follow the sequence when loosening and tightening.

2. Rocker arm assembly:

- do not swap the rocker arms.

3. Cylinder head screw:

- when assembling, replace with a new one;

- follow the sequence of loosening and tightening the cylinder head screws;

- before installation, install the washers in the cylinder head.

4. Cylinder head screw washer:

- to establish on the block of cylinders before installation of covers of support.

5. Pusher with hydraulic compensator:

- do not change places;

- put the working surface down;

- before installation, check the axial run of the camshaft;

- lubricate the work surface;

- before removal to remove loose leaves of bearings of a camshaft.

6. Crackers for fixing the upper plate of valve springs.

7. Valve spring plate.

8. Outer valve spring.

9. Internal valve spring.

10. Oil scraper cap.

11. Valve guide.

12. Pump nozzle.

13. Cylinder head.

14. Camshaft oil seal:

- do not additionally lubricate the working edge of the stuffing box;

- before installation, clean the contact surface of the camshaft from oil by wiping it with a clean rag;

- when installing, seal the groove on the toe of the camshaft (e.g. duct tape).

15. Valves.

16. Liner:

- do not interchange previously used liners (mark when removing);

- the retaining tabs of the liners installed in the cylinder block and in the bearing caps must lie against each other.

17. Camshaft:

- check the axial run;

- measure the radial clearance with a plastic Plastigage gauge:

- maximum permissible value: 0.11 mm,

- maximum radial runout: 0.01 mm.

18. Bearing cap:

- when installing, apply to the seating surfaces of the outer covers of the supports (1 and 5) sealant.

19. Camshaft bearing cap screws: 8 Nm and tighten 1/4 turn (90°):

- when assembling, replace with a new one.

Visitor comments