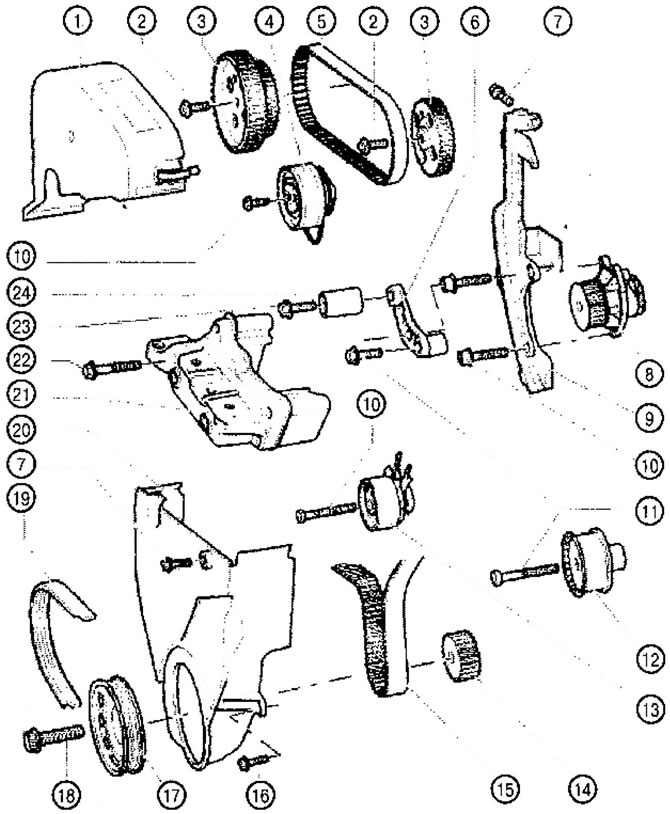

VC 1.064. Timing drive for gasoline engines 1.4 l BCA and BUD:

1. Upper part of the toothed belt guard

2. Camshaft pulley screw

- Tightening: 20 Nm + 90°

- Replace with a new one

- Use a camshaft lock to loosen and tighten

3. Camshaft pulley

- Observe the correct position when installing the toothed belt

4. Tensioner pulley for mated belt drive

5. Timing belt coupled drive

- Before removing, mark the direction of travel

- Check for wear

- Avoid breaks

6. Bracket (only available on BCA engine)

- Fastening tightening: 7-10 Nm

8. Coolant pump

- If damaged, replace as a whole

9. Rear Timing Belt Guard

10. Screw: 20 Nm

11. Screw: 50 Nm

12. Fixed roller toothed belt main drive

13. Main drive belt tensioner

14. Crankshaft pulley

15. Timing belt main drive

- Before removing, mark the direction of travel

- Check for wear

- Avoid breaks

15. Screw: 12 Nm

- Replace with a new one

17. Crankshaft pulley (V-ribbed belt)

18. Crankshaft pulley screw

19. V-ribbed belt

- Before removing, mark the direction of the belt with chalk or a felt-tip pen

- Check for wear

- Avoid breaks

20. Lower part of the toothed belt guard

21. Engine bracket

22. Screw: 50 Nm

- Replace with a new one

23. Screw: 25 Nm (only available on BCA engine)

24. Bypass roller (only available on BCA engine)

Removing

Engine code BCA

1. Remove the air filter housing.

Engine code BUD

1. Remove the air filter housing.

Continued job description for all vehicles

2. Remove the top part of the toothed belt cover.

3. Remove the acoustic cover.

4. Remove the front right fender liner.

5. Mark the running direction of the V-ribbed belt and remove the belt.

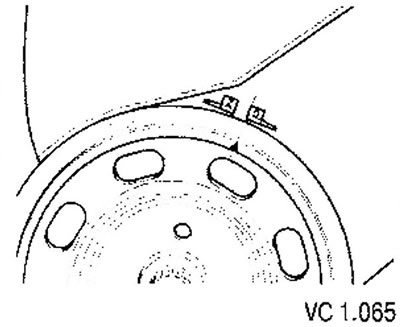

6. Install the crankshaft at TDC of the 1st cylinder. The notch on the V-ribbed belt pulley must align with the edge of the mark (ABOUT).

The fixing holes in the camshaft sprockets must align with the holes in the camshaft housing (arrows).

If the fixing holes are on opposite sides of the sprockets, then the crankshaft must be rotated one more turn.

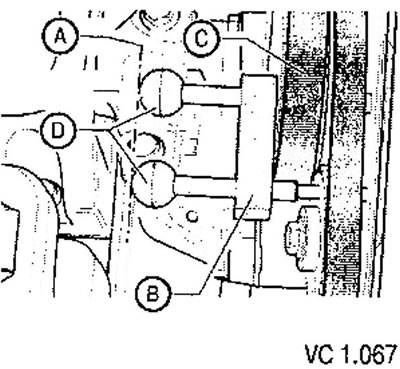

7. Fix both camshaft sprockets with a clamp (see fig. VC1.067) in the following way.

- Insert both locking pins through the holes for fixing the camshaft sprockets until they rest against the holes in the camshaft housing. Both locking pins are inserted correctly if the handles (D) are on the same level as the line (A).

- Slide holder (IN) all the way to the intake camshaft sprocket (WITH).

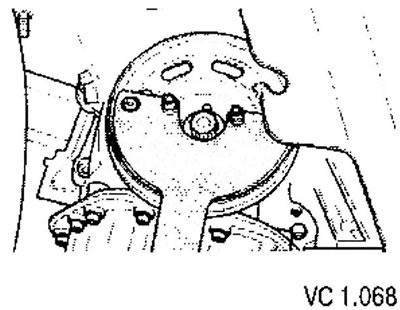

8. Loosen the screw securing the crankshaft pulley, holding the pulley with the tool shown in fig. VC1.068.

9. Remove the poly V-belt pulley. To fix the crankshaft toothed pulley, screw in the fastening screw with two washers again.

10. Remove the lower part of the toothed belt cover.

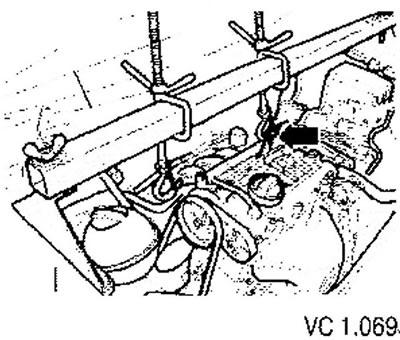

11. Mount the traverse with legs as shown in the figure and hang the motor in the mounting position.

12. Unscrew the filler neck of the windshield washer reservoir.

13. Unscrew the expansion tank of the cooling system and take it aside (hoses remain connected).

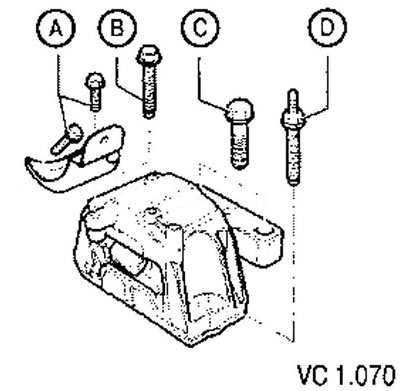

14. Loosen the screws (A), (IN) And (WITH) from the support of the power unit on the side of the poly-V-belt pulley and remove the support of the power unit assembly.

15. Unscrew the engine support from the cylinder head.

16. Mark the running direction of both toothed belts.

17. Remove the toothed belt of the main drive, for which perform the following steps.

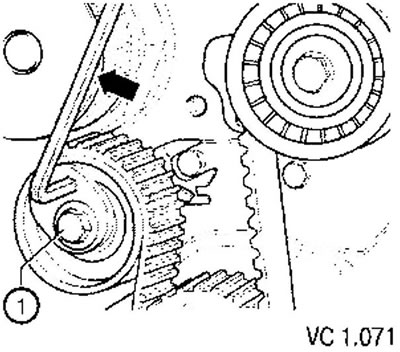

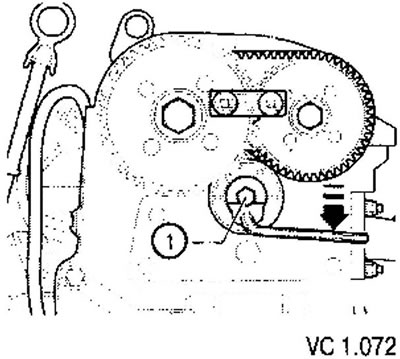

- Loosen the main drive belt tensioner (1) and loosen the toothed belt by turning the tension roller counterclockwise (arrow).

- Loosen the clamping screw of the tensioner.

- Remove toothed belt.

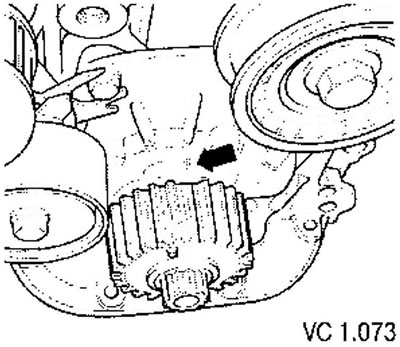

18. Remove the associated drive toothed belt by doing the following.

- Unscrew the tension roller of the toothed belt of the associated drive (1) and loosen the toothed belt by turning the tension roller clockwise.

- Remove the timing belt tensioner from the associated drive.

- Remove toothed belt.

Installation

Initial settings

The pistons must not be at TDC.

The crankshaft sprocket must be bolted to the crankshaft with a screw and two washers replacing the removed crankshaft sprocket.

The camshaft pulleys must be fixed with a camshaft lock through the holes in the camshaft housing and secured against rotation, as the valves may collide with the pistons at top dead center when the camshafts are rotated.

1. Bring the crankshaft into 8MT of the first cylinder. The sheared tooth should line up with the mark on the oil pump (arrow).

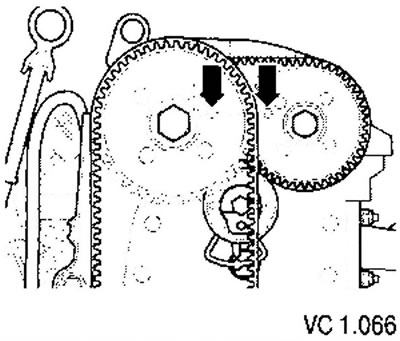

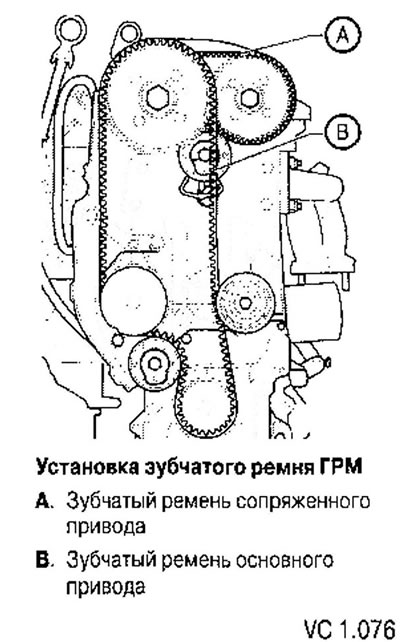

2. To put on a gear belt of the interfaced drive clockwise at first from above on a gear pulley of inlet, then on a gear pulley of an exhaust camshaft. The loose part of the toothed belt must be at the bottom. Observe the running direction of the previously used belt.

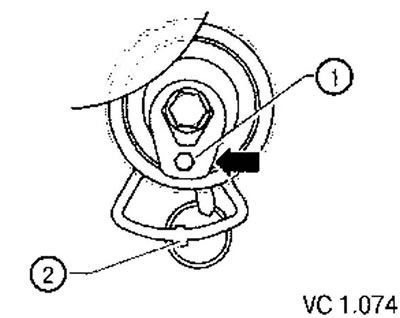

3. Install the associated drive belt tensioner as follows.

- Turn the belt tensioner of the associated drive with an Allen key (1) clockwise towards the indicator window (arrow) (idler pulley in loose position).

- Pull the lower part of the toothed belt of the associated drive up with the tension roller and tighten the fixing bolt of the tension roller.

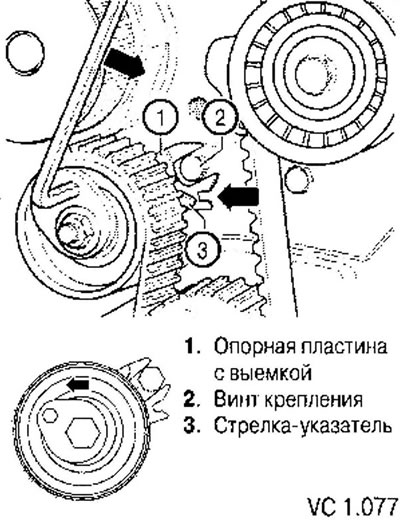

- Tighten the fastening screw by hand. The protrusion of the base plate must fit into the hole in the cylinder head (2).

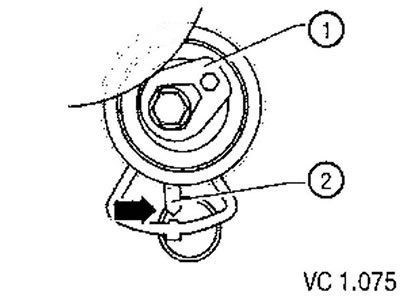

4. Tension the toothed belt by turning the tension roller using the internal hexagon (1) counterclockwise until the arrow (2) will not stop over the toe of the base plate in the indicator window (arrow).

Tighten the clamping screw on the tension roller. Tightening torque: 20 Nm.

The camshafts must remain locked against rotation until the main drive toothed belt is installed.

5. Install the main drive toothed belt, observing the installation direction counterclockwise, first on the water pump pulley, through the tension roller, the crankshaft toothed pulley, the fixed roller and the intake camshaft toothed pulley. A used belt must be installed in accordance with the direction of travel mark previously applied.

6. If the tension roller was previously removed, install it as follows.

- Turn the main drive belt tensioner with an Allen key counterclockwise to the indicated position (arrow).

- Tighten the fixing bolt by hand. Recess in base plate (1) should wrap around the head of the mounting screw (2).

- Tension the toothed belt by turning the tensioning roller in the direction of the arrow until the arrow (3) will not fit over slot in backing plate (arrow).

- Tighten the clamping screw on the tension roller. Tightening torque: 20 Nm.

7. Remove the retainer from the camshaft sprockets.

8. Turn the crankshaft twice in the direction of rotation of the engine until it again stops at the TDC position of the first cylinder.

9. After that, it is necessary to check the position of the toothed belts and tension rollers again.

10. Retension both toothed belts if necessary.

11. Install the lower part of the timing belt cover.

12. Install the crankshaft V-ribbed belt pulley. In doing so, the following must be taken into account.

- The crankshaft pulley mounting screw should be replaced with a new crankshaft pulley.

- When installing the V-ribbed belt pulley, make sure that the toothed belt pulley is fixed.

- Observe the method of tightening a new, lightly greased bolt on the thread.

- Screw the engine mount to the cylinder head. Tightening torque: 50 Nm.

- Install the power unit support.

- Install the top toothed belt guard.

- Install poly V-belt. When installing the V-ribbed belt, observe the correct position on the pulleys.

- Install soundproof cover.

- Install the front right wheel arch liner.

- Screw on the expansion tank of the cooling system.

Engine code BCA: Install the air filter housing.

Engine code BUD: Install the air filter housing.

Visitor comments