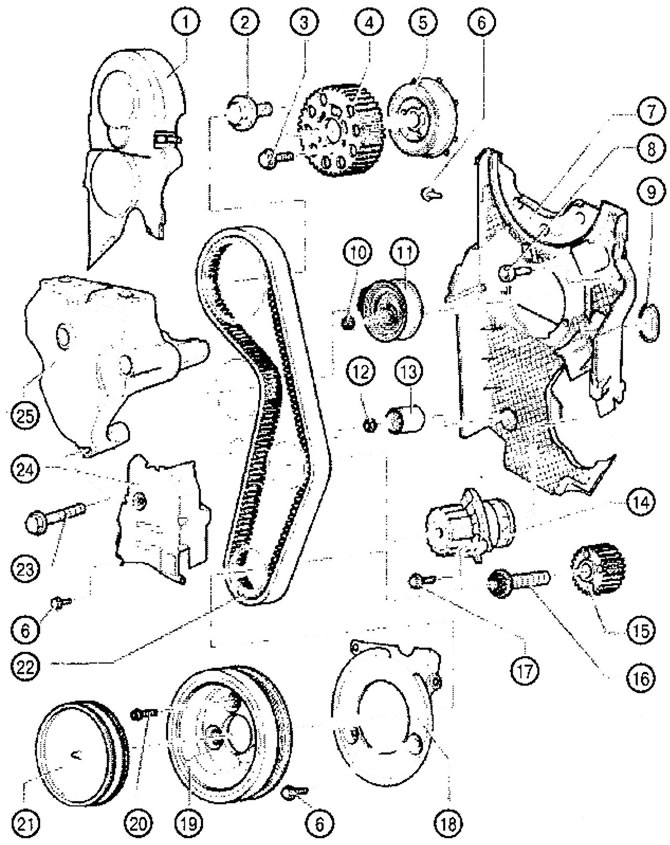

VC1.089. Timing drive for diesel engines:

1. Upper part of the toothed belt guard

2. Screw 100 Nm

3. Screw 25 Nm

4. Camshaft sprocket

5. Gear hub

6. Screw 10 Nm

- replace

7. Rear toothed belt cover

8. Screw 25 Nm

9. O-ring

- replace if damaged

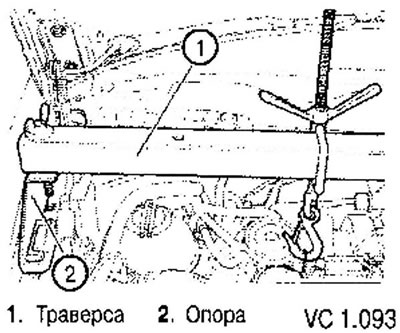

10. Nut 20 Nm + tighten 1/8 turn (45°)

11. Tension roller

12. Nut 20 Nm

13. Overrunning roller

14. Water pump

15. Crankshaft pulley

16. Screw 120 Nm + tighten 1/4 turn (90°)

- replace

17. Screw 15 Nm

18. Lower part of the casing of the toothed belt

19. Crankshaft pulley

- installation is possible only in one position (holes are offset)

20. Screw 10 Nm + tighten 1/4 turn (90°)

21. Lid

22. Toothed belt

23. Screw 40 Nm + 1/2 turn (180°)

- replace

24. The middle part of the toothed belt guard

25. Engine lock

Removal, installation and tension of a toothed belt

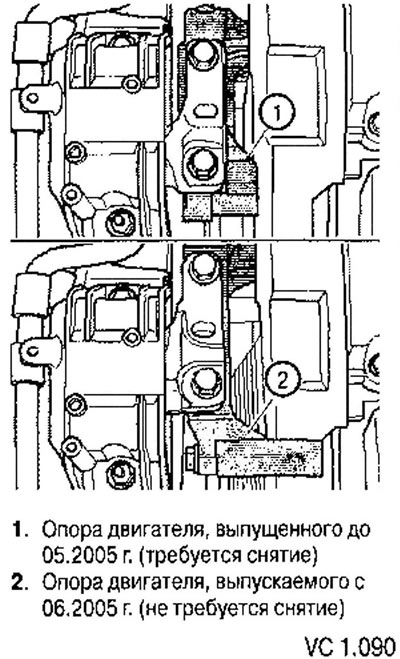

Since 05.2005, a modified engine mount has been used, which does not require the removal of the engine mount and fixing the engine when replacing the timing belt.

Removing, installing and tensioning the toothed belt for vehicles manufactured before 05.2005 (with a support mounted near the engine)

Since model year 2004, a new toothed belt tensioner has been installed.

The tension roller has an additional internal hexagon (arrow). To tension or loosen the timing belt, use an Allen wrench instead of a 2-hole wrench. In this case, the order of work does not change.

Removing

Attention: the timing belt adjustment is carried out only on a cold engine, because. The adjustment position of the tensioner changes depending on the temperature.

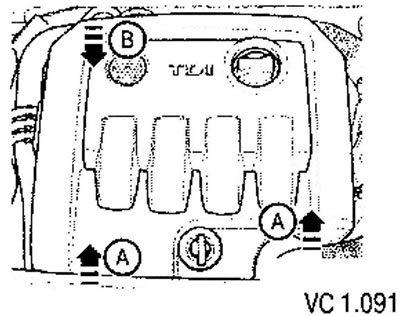

1. Remove the top engine cover. Remove the engine cover by pulling it up with a jerk first (arrows A), and then forward (arrow B) (for detaching the rear attachment).

BJB engines (1.9 l TDI, 77 kW, 105 hp, with unit injector), BSU (1.9l TDI, 55 kW, 70 hp, with unit injector)

2a. Remove the pipe connecting the charge air cooler and the intake manifold.

BLS engines (1.9 l, TDI, 77 kW, 105 hp)

26. Remove the tube connecting the intake air pipe and the air damper motor (V157).

Continued job description for all engines

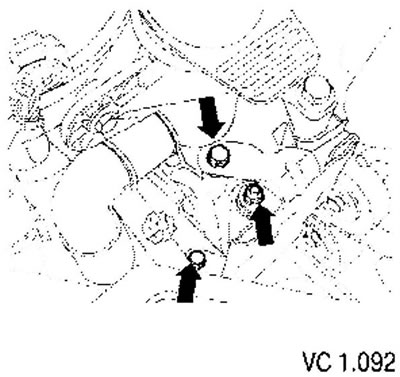

3. Unscrew bracket for fuel filter from engine mounting -arrows.

4. Unscrew the expansion tank of the cooling system and put it aside (hoses remain connected).

5. Remove poly V-belt.

6. Remove the retainer of the V-ribbed belt tensioner.

7. Remove the fender liner of the front right wheel arch.

8. Remove the branch pipe connecting the charge air cooler and the turbocharger.

9. Remove the flexible charge air hose connecting the turbocharger and air filter. To prevent dirt from entering the air path, plug the intake system openings with a clean rag.

10. Remove the crankshaft pulley.

11. To remove the bottom and average casings of a gear belt.

12. Install a traverse with stands and hang the engine by the eye without changing its position. If the toothed belt is removed to remove the cylinder head, then the traverse should be installed with higher racks. Thanks to this, there will be enough space to remove the cylinder head.

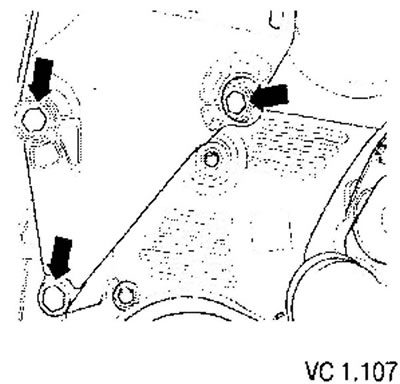

13. Unscrew the bolts of the support on the engine bracket and on the body (arrows) and completely remove the support.

Attention! The support can only be removed after the engine has been suspended using a traverse.

The engine mount bracket may only be loosened after the mount has been removed.

14. Slightly raise the engine with a yoke to unscrew both upper bracket mounting bolts.

15. Slightly lower the engine using the traverse to unscrew the lower bracket mounting bolt.

16. Remove the engine support bracket downwards.

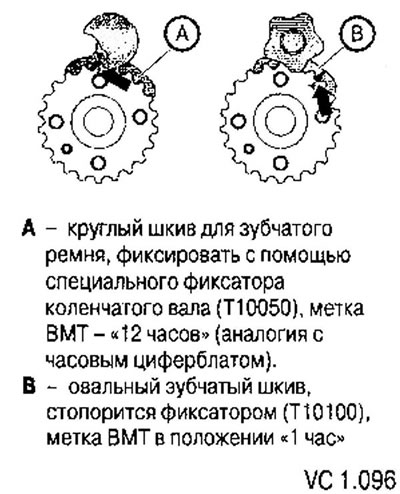

Attention! Some engines may have an oval crankshaft sprocket. In this case, to determine the TDC of the first cylinder, it is necessary to install a special crankshaft retainer (manufacturer's mark: Т10100).

Differences in crankshaft pulleys

Engines with round or oval crankshaft sprocket

17. Set the crankshaft to the TDC position of the first cylinder. To do this, rotate the crankshaft until the mark on its toothed pulley and the toothed segment of the camshaft pulley are at the top. In this case, the mark on the camshaft pulley must match the mark on the timing belt housing behind the pulley (arrow).

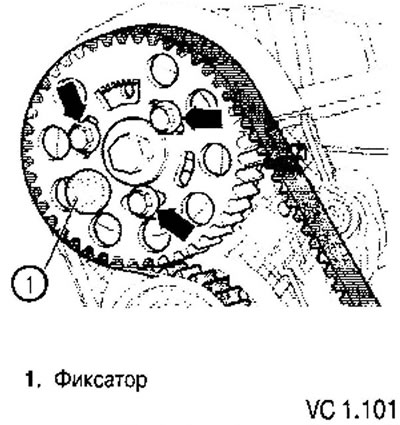

18. Fix the hub with the clamp (3359). To do this, insert the retainer into the hole in the cylinder head through the free arcuate concentric groove on the left side of the camshaft pulley.

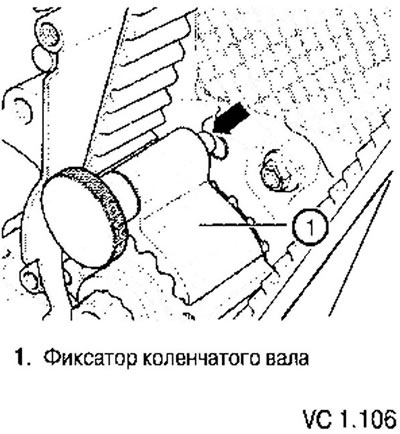

19. Fix the crankshaft pulley with the crankshaft lock (T10050 or T10100). To do this, you need to enter the teeth of the latch into engagement with the teeth of the pulley.

20. Mark the direction of travel of the toothed belt.

Marks on the crankshaft sprocket and on the crankshaft retainer (T10050 or T10100) must match. At the same time, the crankshaft locking pin (T10050 or T10100) must fit into the hole in the sealing flange.

Continued job description for all vehicles

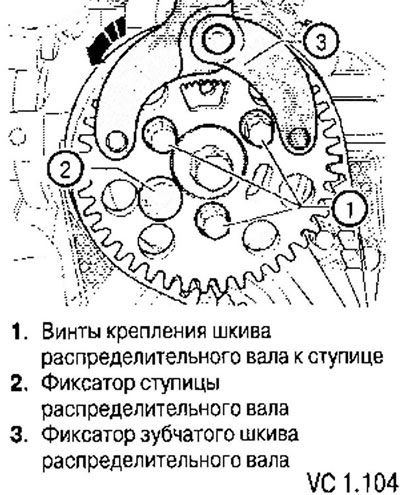

21. Loosen the fastening screws (1) camshaft pulley so that it can rotate in concentric grooves relative to the hub, which is fixedly connected to the camshaft.

22. Loosen the nut of the tension roller.

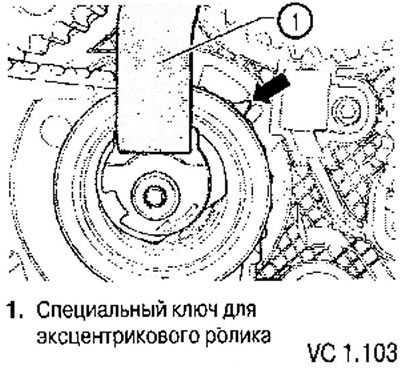

23. Rotate the toothed belt tensioner with a special key (can be made according to the dimensions of the holes in the hub of the tensioner) counterclockwise until the idler pulley can be locked with a suitable locking rod.

24. Turn the tensioner with a special wrench clockwise until it stops and tighten the fixing nut (3) by hand.

25. Remove the toothed belt first from the coolant pump pulley, and then from the remaining toothed pulleys.

Installation

Initial settings:

- The camshaft is fixed with a retainer (3359).

- Fix the crankshaft with a clamp (T10050 or T10100).

- The tension roller is fixed with a retainer (2) and fixed on the right stop.

1. Turn the camshaft pulley so that it takes a middle position in the concentric grooves (arrows).

2. Install the toothed belt on the crankshaft pulley, on the idler pulley, on the camshaft pulley and on the idler pulley.

3. Lastly, install the belt on the coolant pump pulley.

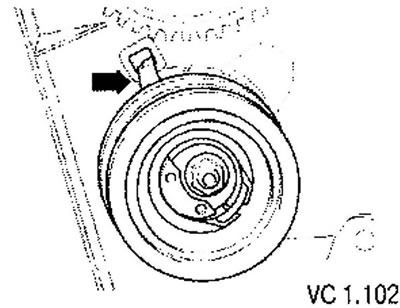

4. Ensure the correct position of the tensioner roller in the rear toothed belt housing (arrow).

5. Loosen the fixing nut of the tension roller and remove the retainer.

6. Carefully turn the idler with a 2-hole wrench clockwise until the pointer is in the middle of the hole in the base (arrow). The fastening nut must not rotate.

7. Holding the tension roller in this position, tighten the fixing nut as follows: 20 Nm and tighten 1/8 turn (45°).

8. Install the camshaft sprocket retainer with pins as shown.

9. Apply force to the retainer in the direction of the arrow to hold the toothed pulley.

10. Tighten in this position the fixing screws of the camshaft pulley (1) torque 25 Nm.

11. Remove the locking pin of the camshaft hub and the crankshaft retainer (T10050 or T10100).

12. Turn the crankshaft two turns so that the piston of the 1st cylinder is in position 8 close to TDC.

13. Fix the camshaft hub with a clamp (2) during rotation of the crankshaft in the working direction.

14. Check whether it is possible to block the crankshaft in this position with a lock (T10050 or T10100). If the crankshaft cannot be fixed, then the following steps must be performed.

- Loosen the fixing screws (1) camshaft pulley.

- Slightly rotate the crankshaft in the opposite direction until the detent pin is almost at the corresponding hole in the crankshaft cover (arrow).

- Rotate the crankshaft in the running direction so that the lock pin enters the hole during rotation.

15. Install the camshaft sprocket retainer with pins as shown.

16. Apply force to the latch in the direction of the arrow to hold the toothed pulley.

17. Tighten in this position the fixing screws of the camshaft pulley (1) torque 25 Nm.

18. Remove the locking pin of the camshaft hub and the crankshaft retainer (T10050 or T10100).

19. Turn the crankshaft two turns so that the piston of the 1st cylinder is in a position close to TDC.

20. Re-check the possibility of fixing the crankshaft.

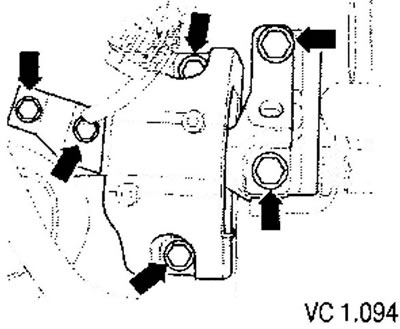

21. Install the engine support on the cylinder block and tighten the fastening screws (arrows) torque 40 Nm + 1/2 turn (180°). Before installing the engine mount, all screws securing the mount bracket must be tightened to the correct torque.

22. Attach the engine mount to the body (replace the screws).

- Tightening torque for screws M8: 20 Nm + 90° (1/4 turn).

- Tightening torque for M10 bolts: 40 Nm + 90° (1/4 turn).

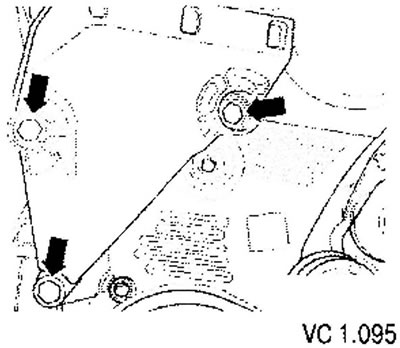

23. Screw the support to the bracket on the engine. To do this, align the seating surfaces properly by shifting the engine using a traverse.

- Tightening torque: 60 Nm + tighten by 90° (1/4 turn).

24. Install the middle and bottom casings of the toothed belt.

25. Install the crankshaft pulley on the hub.

- Tightening torque: 10 Nm + tighten by 90° (1/4 turn).

27. To establish the top protective casing of a gear belt.

28. Install the pipes connecting the charge air cooler to the turbocharger, as well as the charge air cooler to the intake manifold.

29. Install the front right fender liner.

Visitor comments