Attention! If, during the repair, metal chips were found in the engine in large quantities, this may be due to a malfunction of the connecting rod bearing. To avoid subsequent damage after repair work, it is necessary:

- thoroughly clean the oil channels;

- replace oil filter.

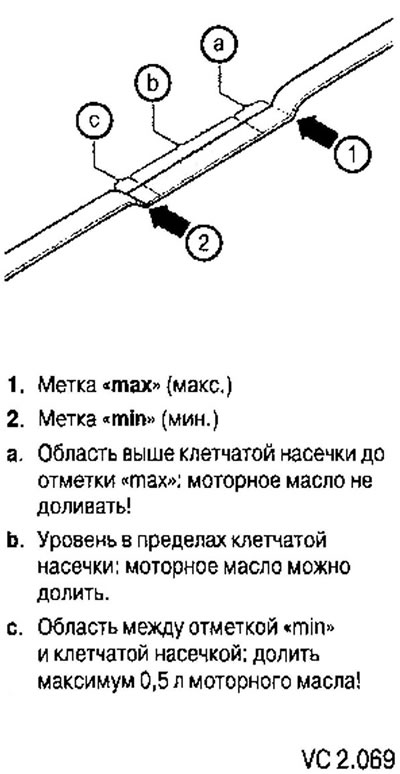

Attention! The oil level must not exceed the mark «max» on the probe. Otherwise, the catalytic converter may be damaged!

For engines with the letter designation BCA

Disassembly and assembly of the oil filler neck.

Continued job description for all vehicles

Removal and installation of the oil pallet.

Removal and installation of the oil pump.

Check oil pressure and oil pressure switch.

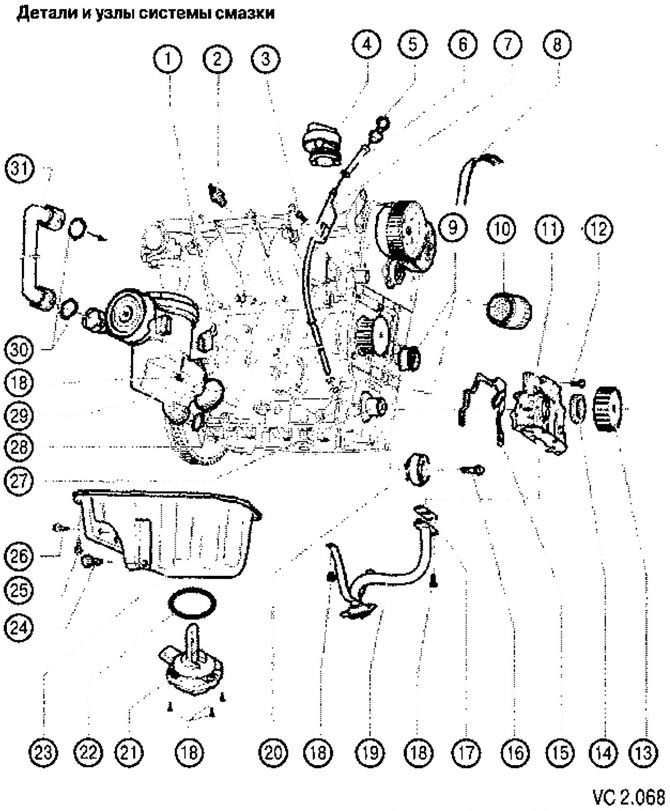

List of parts and assemblies of the lubrication system with technological notes on disassembly and assembly to drawing VC2.068:

1. Connector.

2. Oil pressure sensor (F1): 25 Nm.

3. Screw for fastening the oil dipstick tube: 20 Nm,

4. Oil filler neck (for engines with letter designation BCA).

5. Oil dipstick:

- the oil level must not be above the mark «chopping block»!

6. Dipstick guide tube:

- remove when draining oil.

7. Lower part of the dipstick guide tube.

8. Toothed belt of the main timing drive:

- before removal, mark the direction of travel;

- check for wear;

- avoid cracks.

9. Bypass roller of the toothed belt of the main timing drive.

10. Oil filter:

- unscrew the hexagon;

- tighten by hand.

11. Oil pump:

- is replaced only in the collection;

- at installation to watch a nave of a conducted disk on a cranked shaft;

- mounted on centering bushings.

12. Oil pump mounting screw: 12 Nm.

- when installing, replace with a new one.

13. Toothed pulley of the crankshaft.

14. Front crankshaft oil seal.

15. Oil pump gasket.

16. Screw for fastening the tension roller of the main timing drive: 20 Nm.

17. Oil receiver gasket:

- mounted on centering bushings;

- when installing, replace with a new one.

18 Oil receiver screw: 10 Nm.

10. Oil receiver:

- if dirty, clean the strainer.

20. Tension roller of the main timing belt.

21. Oil level and temperature sensor (G266).

22. Sealing ring of the oil level and temperature sensor.

23. Oil pan:

- before installation, clean the seating surfaces and apply sealant.

24. Oil drain screw: 30 Nm.

25. Oil pan mounting screws: 13 Nm:

- on the flywheel side, unscrew and tighten the screws only with a special tool.

26. Screw: 45 Nm.

27. Oil pump drive hub:

- Before installing the oil pump, lubricate with oil.

28. O-ring oil separator.

29. Oil separator with heated vacuum valve.

30. Ventilation tube O-ring.

31. Ventilation tube.

Marks on the oil dipstick

Oil filler neck of the BCA engine

Visitor comments