- Disassembly of the MCC.

- Checking the valve guides (if necessary - replacement).

- Valve seat processing.

- Valve lapping.

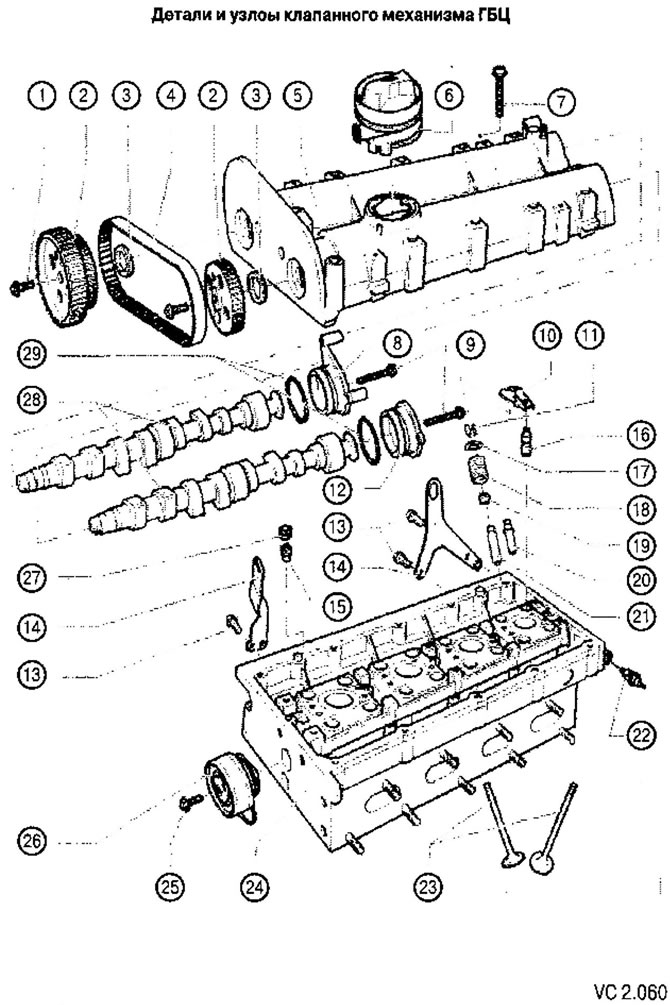

List of parts and assemblies of the MCC valve mechanism with technological recommendations for repair to Figure VC2.080:

1. Intake camshaft screw: 20 Nm + turn 1/4 turn. (90°):

- when assembling, replace with a new one;

- use the toothed pulley lock to loosen and tighten.

2. Camshaft sprocket:

- observe the correct position when installing the toothed belt.

3. Camshaft oil seal:

- Replace only when the camshaft is installed;

- before installation, lightly oil the working edge.

4. Timing belt coupled drive:

- before removal, mark the direction of travel;

- check for wear;

- avoid cracks.

5. Camshaft housing:

- carefully clean the landing surfaces; they must be free of oil and grease;

- apply sealant before installation;

- during installation, install from above vertically on the studs and dowel pins.

6. Oil filler neck:

- engine with letter designation BCA:

- replace if damaged;

- engine with letter designation BUD:

- has only one oil filler cap.

7. The screw of fastening of the case of camshafts: 10 Nm + to tighten on 1/4 about. (90*):

- when assembling, replace with a new one;

- tighten from the center to the edges.

8. End cover of the camshaft housing (intake camshaft).

9. Screw of fastening of an end cover of the case of camshafts (intake camshaft): 10 Nm.

10. Rocker:

- check for jamming;

- lubricate the work surface;

- when installing, fix it on the support with a locking bracket.

11. Conical crackers.

12. Cover.

13. Screws for fastening the lifting eye: 20 Nm.

14. Sling eye.

15. Check valve: 6 Nm:

- do not overtighten, otherwise the valve may stick;

- clean the thread and install with sealant.

16. Roller arm support with hydraulic clearance compensator.

- do not change places;

- lubricate the work surface;

- before installation, check the axial run-up of the camshaft.

17. Valve spring plate.

18. Valve spring:

- Removal and installation: with the cylinder head removed, using a valve spring compressor.

19. Valve stem seals.

20. Valve repair guide bushing with collar.

21. Valve guide.

22. Oil pressure sensor (F1): 25 Nm.

23. Valves:

- not subject to cutting or grinding, only lapping is allowed.

24. Cylinder head.

25. Screw for fastening the timing belt tensioner: 20 Nm.

26. Tension roller of the mated belt drive.

27. Locking screw:

- the maximum allowable screwing depth when counting from the contact surface with the camshaft housing 2 mm.

28. Camshafts:

- lubricate with oil before installation (including thrust bearing surface);

- after installation, replace the seals.

29. O-ring end cap:

- when assembling, replace with a new one.

Visitor comments