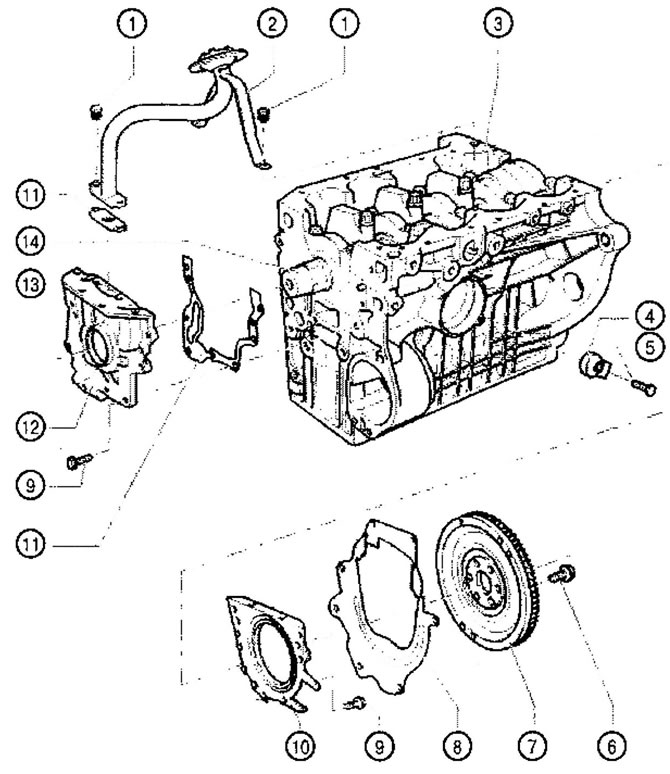

Pic. VC2.017. Details and knots. Aluminum block:

1. Screw: 10 Nm

2. Oil receiver

3. Aluminum block

4. Knock sensor

5. Screw: 20 Nm

- The tightening torque affects the operation of the knock sensor

6. Flywheel mounting screw 60 Nm + tighten 1/4 turn (90*)

- When installing, replace with a new one

7. Flywheel

- When removing or installing, secure

8. Protective plate

- Must be mounted on centering sleeves

9. Oil pump mounting screw 12 Nm

- When installing, replace with a new one

10. The rear cover of the cylinder block with the crankshaft oil seal

- With engine speed sensor (G28) (not shown in the picture)

- Tightening torque of the engine speed sensor (G28): 5 Nm

- Replaced only as an assembly with an oil seal and a master rotor of the sensor

11. Gasket

- When installing, replace with a new one

12. Oil pump

- Replaced only in assembly

- Mounted on centering bushings

13. Front crankshaft oil seal

- When installing, replace with a new one

14. Hub for oil pump and timing drive

- Lubricate with oil before installing the oil pump

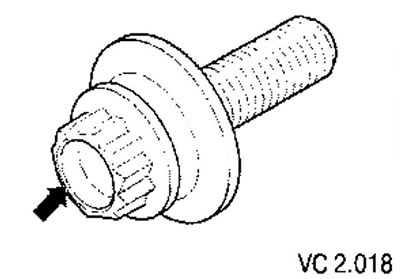

Tightening the crankshaft pulley screw

Two types of mounting screws can be used to fasten the crankshaft pulley.

A new screw can be identified by the recess in the head (arrow).

Tightening torque: 150 Nm + tighten 1/2 turn. (180°).

When tightening, secure the V-ribbed belt pulley.

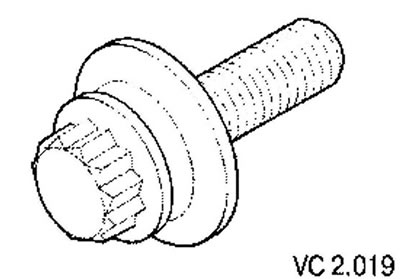

Screw «old»

Tightening torque: 90 Nm + tighten 1/4 turn. (90°).

When tightening, secure the V-ribbed belt pulley.

Visitor comments