Removal and installation of the camshaft housing

Attention!

- In this engine, the camshafts are located in the camshaft housing. Therefore, the camshaft housing may only be removed after both toothed belts have been removed first.

- The seating surface of the camshaft housing must not be machined.

For engines with the letter designation BCA

1. Remove the air filter housing.

For engine codes BUD

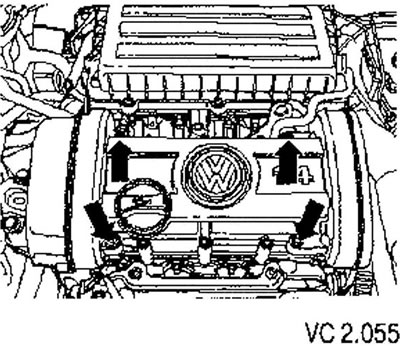

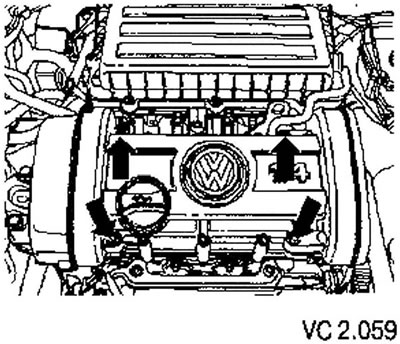

1. Remove the screws (arrows) and remove the cover from the camshaft bearing housing.

Continued job description for all vehicles

2. Remove both toothed belts.

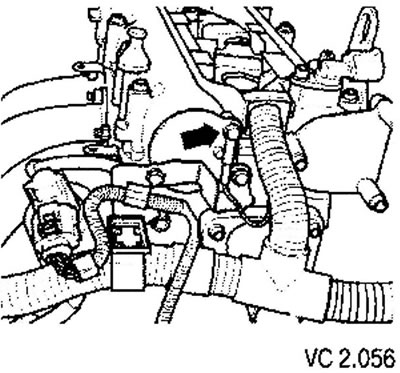

3. Unscrew the ground cable from the camshaft housing (arrow).

For engines with the letter designation BCA

4. Remove the oil filler neck.

Continued job description for all vehicles

5. Remove ignition coils.

6. Remove the wiring box with wiring harness from the camshaft housing.

7. To remove the vent pipeline of system of cooling from the case of camshafts..

8. Disconnect the connector from the camshaft position sensor.

9. Unscrew the fastening bolt of the rear cover of the toothed belt in the area of the right lifting eye for.

10. Loosen and unscrew the screws securing the camshaft housing from the edges to the center, alternating crosswise.

11. Gently raise the camshaft housing.

Installation

Conditions:

- The pistons must not be at TDC.

- The camshaft pulleys are fixed with a camshaft lock through calibrated holes in the camshaft housing and are secured against rotation.

- Sealant residue must be removed from the cylinder head and camshaft housing using a standard sealant cleaner.

- Avoid getting dirt and sealant residues into the cylinder head.

- The seating surfaces must be thoroughly cleaned. They should not leave traces of oil.

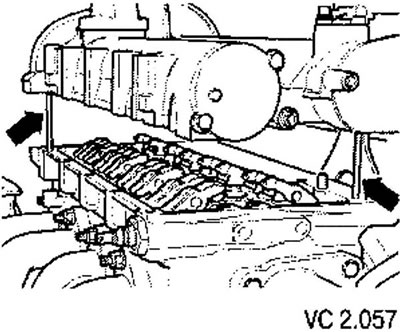

1. Apply sealant to the clean seating surface of the camshaft housing in a thin, even bead (see the shaded area in fig. VC 2.057).

Attention! Layer (roller) sealant must not be too thick, otherwise excess sealant may get into the lubrication channels, resulting in engine damage.

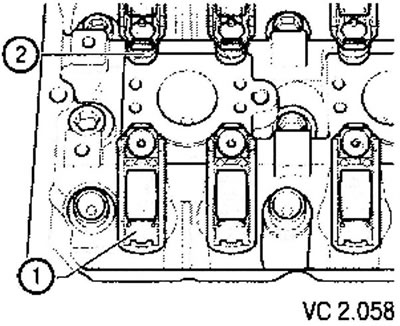

The roller lever must lie correctly on the end of the valve stem (1), and on the corresponding support (2) must be secured with a clamp.

2. Before installing the camshaft housing, two spacer screws must be screwed in (M6x70) into the cylinder head.

3. Carefully install the camshaft housing vertically from above on the spacer bolts and dowel pins of the cylinder head (arrows).

Attention! It is unacceptable to get oil on the applied sealant layer.

4. Tighten the new camshaft housing screws evenly and crosswise, alternating from the center to the edges. At the same time, care must be taken to ensure that the camshaft housing is not warped.

Tightening torque: 10 Nm + tighten 1/4 turn (90°).

Attention! After installing the camshaft bearing housing, the sealant should cure for approximately 30 minutes.

5. Further installation is carried out in the reverse order of removal.

For engine codes BUD

Mounting screw tightening torque (arrows) caps to the camshaft bearing housing: 10 Nm.

Visitor comments