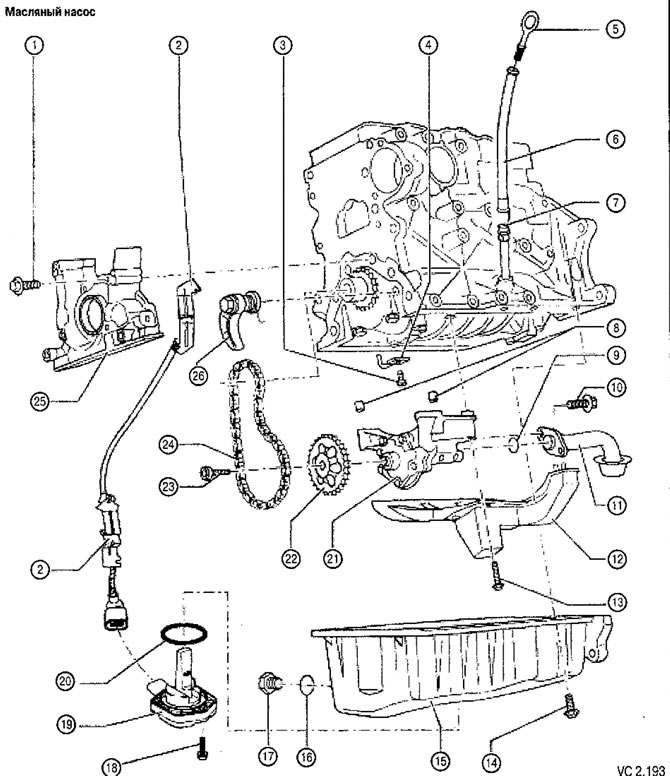

List of parts of the lubrication system with technological notes on repair to Figure VC2.193:

1. Screw of fastening of a forward cover of the block of cylinders: 15 Nm.

2. Bracket for oil level and temperature sensor wiring harness (G2S6).

3. Screw for fastening the piston oil cooling nozzle with a pressure reducing valve: 27 Nm:

- actuation pressure: 0.13-0.16 MPa (1.3-1.6 bar);

- Applies to BGU engines only.

4. Piston oil cooling nozzle:

- Applies to BGU engines only.

5. Oil dipstick:

- the oil level must not be higher than the max mark!

6. Top of dipstick guide tube:

- Remove when draining oil.

7. Lower part of the guide tube.

8. Centering sleeves.

9. O-ring:

- when assembling, replace with a new one.

10. Oil receiver mounting screw: 15 Nm.

11. Oil receiver:

- if necessary, clean the filter mesh.

12. Oil bath dampener in the oil sump.

13. Screw for fastening the oil bath stabilizer in the oil sump: 15 Nm.

14. Oil pan fixing screw: 15 Nm.

15. Oil pan.

16. O-ring for oil drain plug, non-removable.

17. Oil drain screw: 30 Nm:

- Replace the plug complete with sealing ring.

18. Screw for fastening the oil level and temperature sensor (G266):10Hm.

19. Oil level and temperature sensor (G266).

20. O-ring:

- when assembling, replace with a new one.

21. Oil pump:

- with pressure reducing valve 1.2 MPa (12 bar);

- before installation, check the presence of centering bushings that determine the relative position of the oil pump and the cylinder block;

- if there are scratches or scuffs on the working surfaces and gears, replace the entire pump.

22. Chain drive sprocket.

23. Chain sprocket screw: 20 Nm, then tighten by 90°.

24. Chain.

25. Front cover of the cylinder block.

26. Chain tensioner with shoe: 15 Nm:

- compress the spring before installing.

Visitor comments