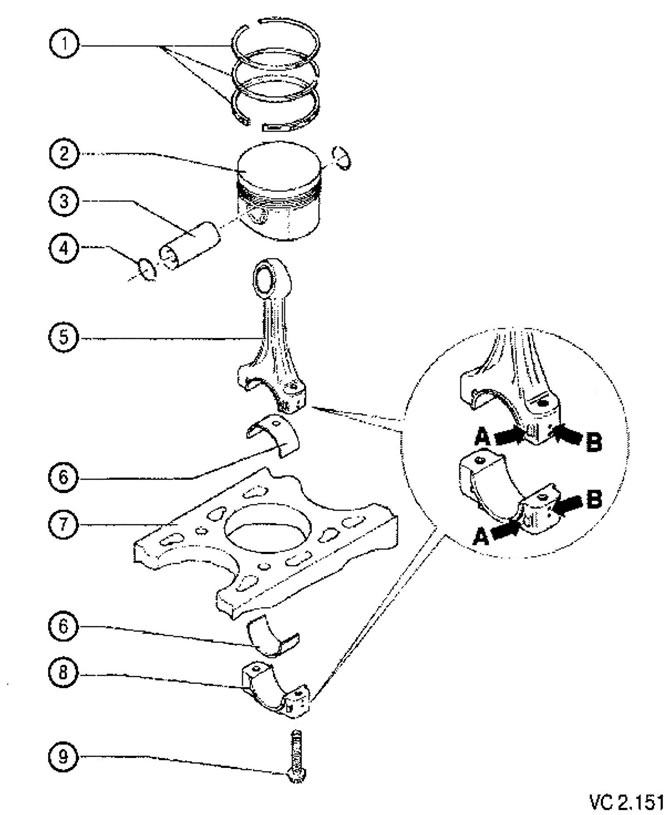

The list of elements of the cylinder-piston and connecting rod-piston groups with technological recommendations for repair to Figure VC2.150:

1. Piston rings:

- the locks of the rings must be located at an angle of 120°relative to each other;

- remove and install using pliers for installing piston rings;

- marking «TOR» must face the piston crown;

- check thermal clearance (gap in the castle);

- check the height clearance between the groove and the ring.

2. Piston:

- mark the mounting position and belonging to the cylinder;

- the arrow on the piston crown points to the side of the V-ribbed belt pulley;

- When installing, use a piston ring compressor.

3. Piston pin:

- if installation is difficult, heat the piston up to about 60°C;

- remove and install using a mandrel.

4. Retaining ring.

5. Connecting rod:

- can only be replaced as a set;

- mark belonging to the cylinder (IN);

- installation position: marks (A) facing the poly V-belt pulley.

6. Connecting rod bearing shell:

- install in the proper position;

- used liners should not be interchanged;

- install in the center;

- allowable values of axial movement along the neck:

- for new: 0.05-0.31 mm;

- maximum permissible value: 0.37 mm;

- determine the radial clearance using a Plasligage measuring wire;

- for a new one: 0.01 -0.06 mm;

- maximum permissible value: 0.09 mm;

- when measuring the radial clearance, do not rotate the crankshaft.

7. Cylinder block;

- check the diameter of the cylinder;

- check the dimensions of the pistons and cylinders.

8. Connecting rod bearing cap:

- install in the proper position;

- in the manufacture, the connector of the cover and the connecting rod is made by a gap, therefore the cover fits only to its connecting rod and only in one position. Avoid damage to the fracture surface (joint of connecting rod with cover).

9. Connecting rod bolt, tightening torque 30 Nm and tighten 1/4 turn (90°):

- head TORX E10;

- when assembling, replace with a new one;

- lubricate the thread and bearing surface of the head;

- To measure the radial clearance in the connecting rod bearing, tighten to 30 Nm, short of 90°.

Visitor comments