Attention!

- If there are cracks in the cylinder head between the valve seats, as well as between the valve seat rings and the threaded holes for the spark plugs, and if the width of these cracks does not exceed 0.3 mm, and the depth does not exceed 4 threads in the holes for the spark plugs, then The cylinder head can be operated without reducing the service life.

- The cylinder head and camshaft housing are replaced only as an assembly.

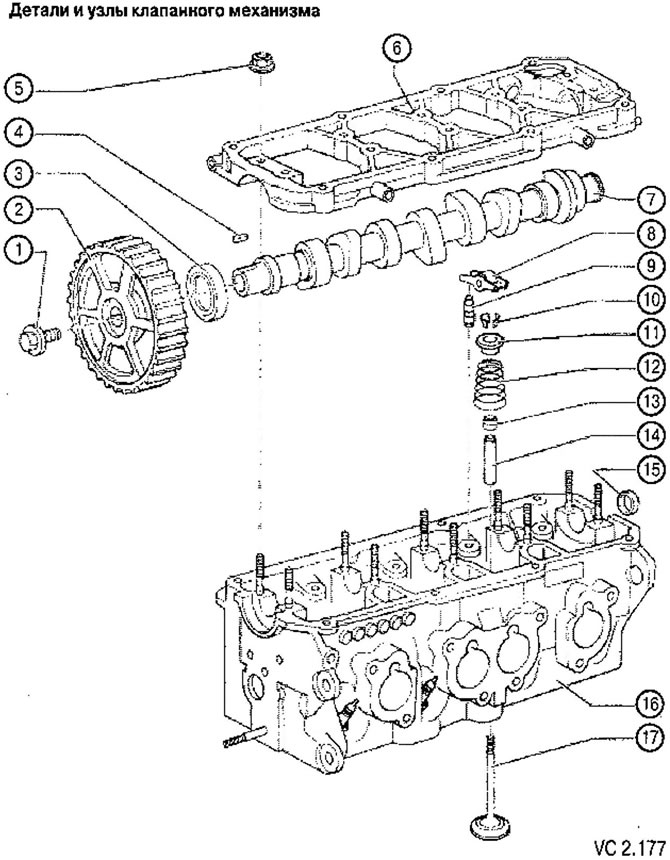

List of parts and assemblies with notes on installation work to Figure VC2.177:

1. The screw of fastening of a gear pulley of a camshaft 100 Nm.

- when loosening and tightening, use a lever to hold the pulley.

2. Camshaft pulley.

3. Camshaft oil seal:

- when assembling, replace with a new one.

4. Key.

5. Nut of fastening of the case of a camshaft: 23 Nm.

6.Camshaft housing integrated top plain bearing caps:

- mating planes are not subject to processing;

- support (1) from the side of the V-ribbed belt pulley;

- observe the sequence of tightening the fasteners of the camshaft bearings;

- carefully apply the sealant to the lower surfacing plane and into the groove for the sealant.

7. Camshaft:

- measure the radial clearance with a Plastigage measuring wire, limit value: 0.1 mm;

- radial run-out: maximum 0.04 mm.

8. Roller arm:

- check the rollers for jamming;.

- lubricate the work surface;

" when installing, fix it on the support with a locking bracket.

9. Roller arm support with hydraulic compensator:

- do not change places;

- Lubricate the work surface.

10. Crackers for fastening the valve spring.

11. Valve spring plate.

12. Valve spring.

13. Oil seal

- when assembling, replace with a new one.

14. Valve guide

15. Plug:

- install flush;

- to remove, pierce the rubber wall in the middle with a screwdriver and remove the cover.

16. Cylinder head:

- mating planes on the camshaft side are not subject to processing;

- processing of valve seats.

17. Valves:

- not subject to processing, only lapping is allowed.

Visitor comments