Removing

Attention!

- Mounting planes of the camshaft housing (from below) and cylinder head (above) are not subject to mechanical processing.

- The camshaft bearings are integrated into the cylinder head and into the camshaft housing. Before removing the camshaft housing, the toothed belt must be loosened.

- If the camshaft frame is removed, then the camshaft oil seal and the cover on the back of the cylinder head must be replaced when it is subsequently installed.

1. Remove the engine cover.

2. Remove intake manifold.

Attention! The intake ports on the bottom of the intake manifold must be covered with a clean cloth.

3. Remove the upper part of the timing case.

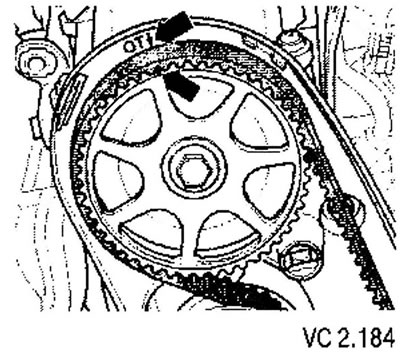

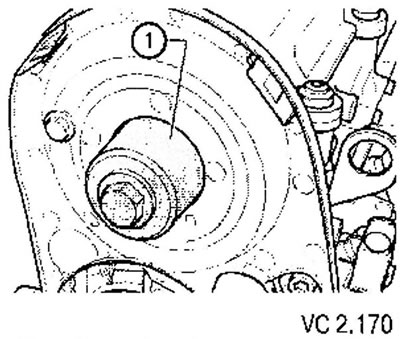

4. Set the camshaft pulley to the TDC position of the first cylinder. The mark on the camshaft sprocket must align with the arrow on the toothed belt guard.

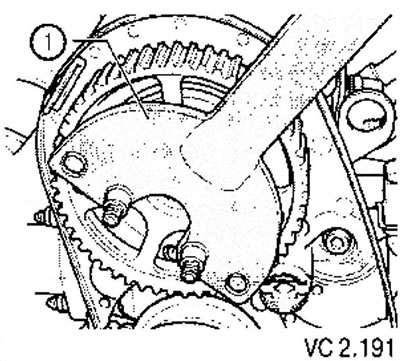

5. Loosen the tension roller and remove the toothed belt from the camshaft pulley.

6. After that, slightly turn the crankshaft back.

7. Remove the camshaft sprocket.

8. Remove the feather key from the camshaft.

9. Unscrew the screws securing the valve cover, loosening them from the edges to the middle.

10. Remove the valve cover.

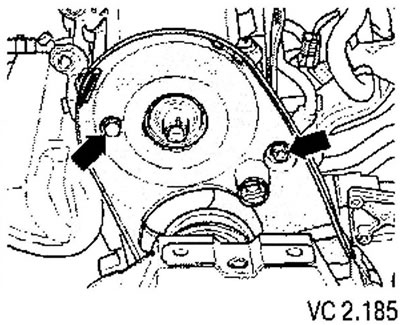

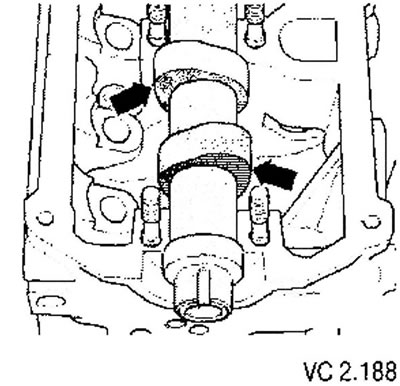

11. Remove the bolts securing the rear timing cover (arrows).

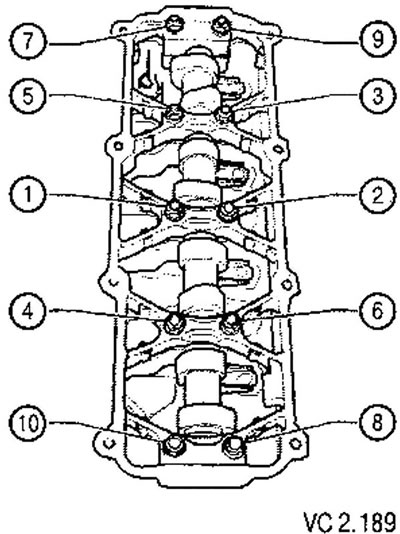

12. Unscrew the nuts of supports No. 5, 1 and 3. In turn, crosswise, release the covers of supports Nos. 2 and 4.

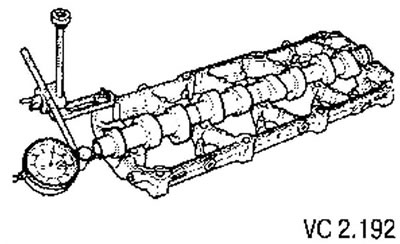

13. Remove the camshaft housing.

14. Carefully remove the camshaft vertically upwards and place it on a clean surface.

15. Remove the roller levers together with the supports. Lay roller arms and supports on a clean surface. At the same time, make sure that during the subsequent installation, the supports and levers are in their original places.

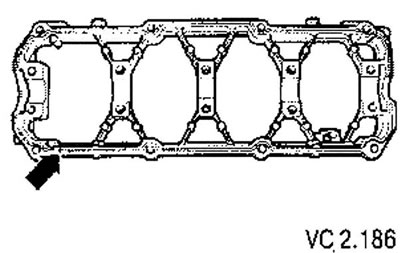

16. Remove sealant residue from groove (arrow) camshaft housing, as well as from the mating plane.

Do not allow dirt or sealant residues to enter the cylinder head.

Installation

Installation conditions:

- There must be no traces of oil on the mating surfaces.

- When installing the camshaft housing or camshaft, the cams for the first cylinder must face up.

- The pistons must not be at TDC.

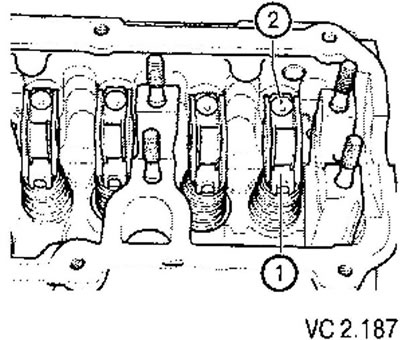

1. Install the roller lever supports in the cylinder head and install the appropriate roller levers on them and on the ends of the valve stems.

2. The roller lever must lie correctly on the end of the valve stem (1), and on the corresponding support (2) be secured with a clamp.

3. Lubricate the running surfaces of the camshaft.

4. Carefully install the camshaft on the cylinder head bearings.

5. 8 clean groove camshaft housing (arrow) apply an even bead of sealant so that it protrudes slightly from the groove.

Spread the sealant evenly over the entire mating surface.

Attention!

- The sealant must not be applied too thickly. If necessary, remove excess sealant with a lint-free cloth.

- Installation of the housing and tightening of the bolts of its fastening must be carried out without interruption, since the sealant begins to harden immediately after application.

6. Install the cover on the back of the cylinder head.

7. Install the camshaft frame and lightly tighten, in turn and crosswise, the support covers No. 2 and

4. After that also lightly tighten the nuts of supports nos. 3, 1 and 5.

8. Tighten nuts to 23 Nm in sequence.

9. Install the valve cover. Tighten the bolts crosswise from the middle to the edges.

10. Install the rear timing case.

11. Install the stuffing box along the guide sleeve and press it in with a mandrel with a screw until it stops.

Attention! Place a standard M12 washer under the screw head to avoid wear on the mandrel.

12. Install the feather key on the camshaft.

13. Install the camshaft sprocket. When tightening the screw securing the toothed pulley, it is necessary to hold the camshaft pulley with a lever.

Tightening torque: 100 Nm.

Attention! When rotating the camshaft, the crankshaft must not be in the TDC position. Possible damage to valves and piston crowns.

Further installation is carried out in the reverse order of removal.

Attention! After mounting the body and valve cover, wait approximately 30 minutes for the sealant to dry.

Camshaft, axial run check

Maximum permissible value: no more than 0.17 mm.

Visitor comments