Removing

1. Remove the engine cover.

2. Remove poly V-belt.

3. Disconnect the upper hose from the expansion tank of the cooling system.

4. Remove the expansion tank and put it aside.

5. Remove the top part of the timing case.

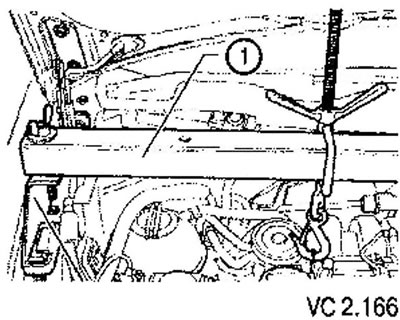

6. Install the traverse (1) with an adapter and hang the engine so that its supports are not loaded.

7. Remove the bottom soundproof casing.

8. Remove damper from polycarbonate belt pulley.

9. Remove the middle and lower parts of the timing case.

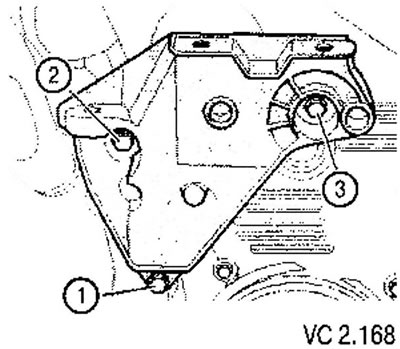

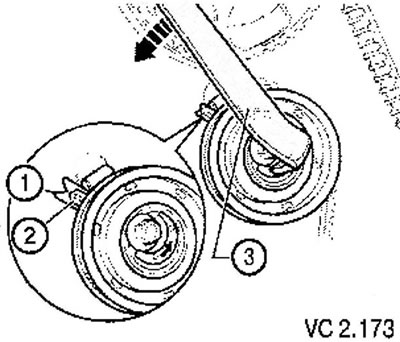

10. Unscrew the lower fixing bolt (1) engine mount bracket.

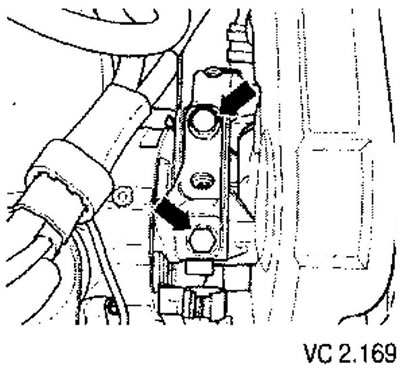

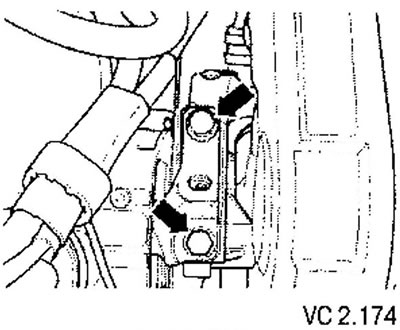

11. Unscrew the screws securing the engine mount (arrows) and completely remove the support.

12. Raise the motor with the yoke as far as possible, so that both upper mounting bolts can be loosened and unscrewed (2) And (3) engine mount bracket.

13. Remove the engine support bracket by lifting it 8 up.

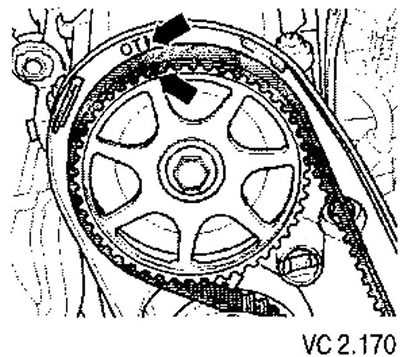

14. Rotating the crankshaft, set the camshaft pulley to the TDC position of the first cylinder. The mark on the camshaft sprocket must align with the arrow on the toothed belt guard.

15. Mark the direction of travel of the toothed belt.

16. Loosen the tension roller and remove the toothed belt.

17. After that, slightly turn the crankshaft back.

Installation

Attention! When rotating the camshaft, the crankshaft must not be in the TDC position. Possible damage to valves and piston crowns.

1. Install the timing belt on the crankshaft pulley and coolant pump (install, observing the correct direction of movement of the belt).

2. Bring the camshaft in such a position that the marks on the toothed pulley and the toothed belt housing coincide.

3. Install the middle and bottom parts of the timing case.

4. Install the damper on the V-ribbed belt pulley with new screws.

Tightening torque: 10 Nm and tighten 1/4 turn (90°).

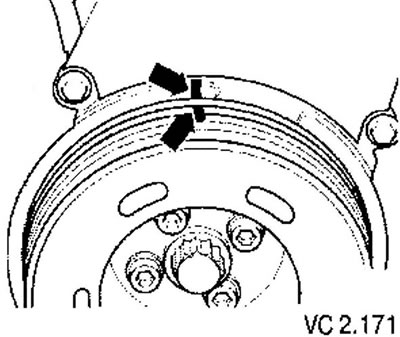

5. According to the marks on the vibration damper, bring the crankshaft to the TDC position of the first cylinder (arrow).

6. Install the toothed belt on the tension roller and camshaft pulley.

Attention! Pay attention to the correct roller tension in the cylinder head.

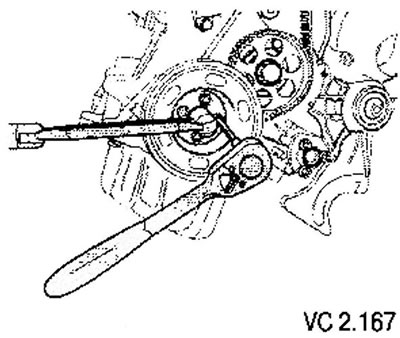

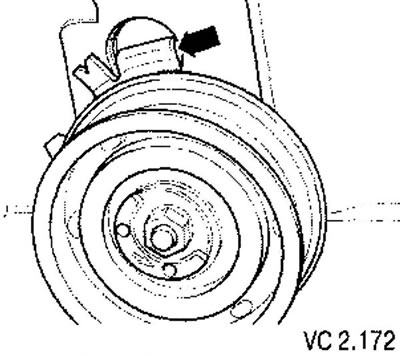

7. Tension toothed belt. To do this, use a 2-hole nut wrench to turn the eccentric to the left (in the direction of the arrow), while the arrow (2) will not be slightly higher risks (1) (the belt will be tightened).

Attention!

- Repeat this action (belt pull) five times to strap «sat down».

- After that, loosen the belt so that the risk (1) and arrow (2) were combined.

- Tighten the fixing nut to 20 Nm.

8. Rotate the crankshaft two turns in the direction of engine rotation and set it again in the position corresponding to the TDC of the first cylinder. At the same time, the last 45' (1/8 turn) the crankshaft must rotate without stopping (increase in effort).

9. Check the belt tension again. Correct position: risk and arrow are aligned.

10. Check the timing again.

If the marks do not match: repeat the timing adjustment.

11. Install bracket (above) on the cylinder block and tighten both upper screws to 45 Nm.

12. Lower the motor to its final mounting position.

13. Install the lower fixing bolt and tighten it to 45 Nm.

14. Install the engine mount assembly.

15. Using new bolts, screw the support to the engine bracket (arrows), while lowering the engine with the help of a traverse so that the bracket comes into contact with the support.

Tightening torque: 60 Nm and tighten by 90° (1/4 turn).

16. Remove the traverse.

17. Install the upper part of the timing case.

18. Install poly V-belt.

19. Install the expansion tank of the cooling system.

20. Install the bottom soundproof casing.

21. Install the engine cover.

Visitor comments