1. Install new centering sleeves in the cylinder block (for the correct alignment of the engine and gearbox).

2. Install the intermediate plate on the centering sleeves of the motor flange (arrows).

3. Apply a thin layer of lubricant to the input shaft splines.

4. Check and install the clutch.

5. When installing the power unit, make sure that it does not catch on the subframe or on the radiator.

6. Slightly moving the power unit, achieve its installation on the engine and gearbox mounts without interference and distortion, if necessary, loosen the fastening of the supports, including to the body.

7. Install the lower support of the power unit.

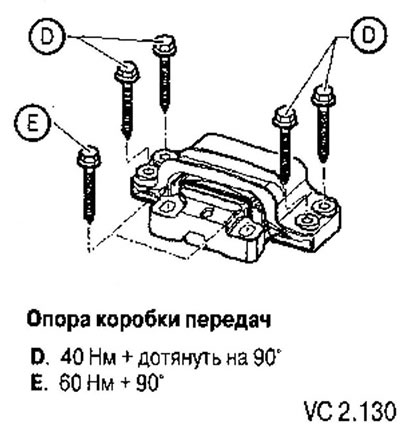

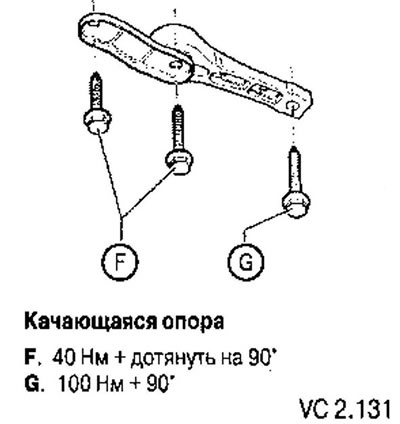

The moments of an inhaling of fixture of a suspension bracket of the power unit

| Threaded connection diameter | Torque |

| M6 | 10 Nm |

| M8 | 20 Nm |

| M10 | 45 Nm |

| M12 | 60 Nm |

8. Install the right drive shaft and connect the left drive shaft to the gearbox.

9. To establish a reception pipe of the muffler.

10. Install the gearshift mechanism, adjust if necessary.

11. Connect the tube (IN) to the quick coupling of the hydraulic clutch by securely snapping the clip (A).

12. Remove air from the hydraulic clutch actuator.

13. Install the air conditioner compressor.

14. Install poly V-belt.

15. Install soundproof casing.

16. Install the plenum box shield.

17. Fill in coolant.

18. Connect the terminals to the battery.

19. Interrogate the fault memory and remove from it all the errors that may have occurred during the installation of the engine.

20. Take a test drive.

21. After that, repeat the diagnostics of the vehicle systems and, if necessary, eliminate the errors that have arisen.

|  |

Visitor comments