List of parts and assemblies with notes on installation work to Figure VC2.147:

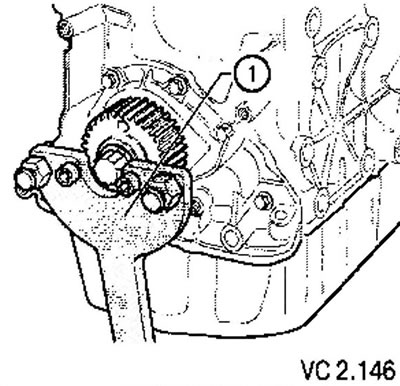

1. Oil pump.

2. Oil pump mounting screw: 15 Nm.

3. Oil pump drive sprocket.

4. Inserts 1, 2, 3, 4 and 5 of the crankshaft bearings are installed:

- in the cover - without lubrication groove;

- in the cylinder block - with an oil groove;

- previously operated liners cannot be interchanged (mark when removing).

5. Screws of fastening of a cover of the radical bearing; 40 Nm and tighten by 90° (1/4 turn):

- when assembling, replace with a new one;

- thread to the head;

- to measure the radial clearance, tighten to 40 Nm, short of 90°.

6. Main bearing caps:

- bearing cover 1: on the poly-V-belt pulley side;

- the retaining projections of the liners installed in the cylinder block and in the covers must be installed against each other.

7. Bearing shell 3:

- previously operated liners cannot be interchanged (mark when removing).

8. Setting rotor of the engine speed sensor (G28);

- the driving rotor should be replaced with a new one after each unscrewing of the fixing screws;

- installation is possible only in one position (holes are offset).

9. Drive rotor screw: 10 Nm and tighten 1/4 turn (90°):

- when assembling, replace with a new one.

10. Crankshaft:

- allowable values of the axial run;

- for a new one: 0.07-0.23 mm;

- maximum permissible value: 0.30 mm;

- the radial clearance should be determined using a plastic Plastigage gauge;

- for new: 0.01-0.04 mm;

- maximum permissible value: 0.07 mm;

- do not rotate the crankshaft when measuring the radial clearance.

11. Thrust half ring:

- are installed in the cylinder block on both sides of the 3rd main bearing;

- the inscription must face the bearing.

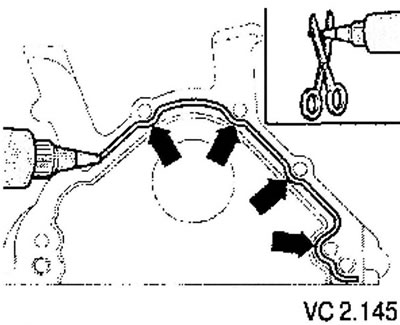

Apply sealant as shown (arrows), on the degreased contact surface of the lid. The thickness of the sealant strip should be 2-3 mm.

Notes on the installation technology of the rear crankshaft cover

Before applying the sealant, protect the seal with a clean cloth.

The thickness of the sealant layer should not be more than 2-3 mm, otherwise the sealant protruding from the joint can get into the oil pan and clog the oil receiver screen.

The sealant must not be expired.

The oil pan must be installed within 5 minutes of applying the silicone sealant.

Install the cover together with the stuffing box using a guide bush.

After installing the part, wait approximately 30 minutes for the sealant to dry. Only after that you can fill in engine oil.

After that, immediately install the cover, slightly tightening the screws by hand.

Tighten cover fixing screws. Tightening should be done evenly by tightening opposite screws in pairs. Tightening torque: 15 Nm.

Remove excess sealant that has come out of the joint when tightening.

Install oil pan.

If the cover was installed without an oil seal, install the oil seal.

Install the crankshaft sprocket and secure it with the retaining device.

Attention!

- The contact surfaces of the toothed pulley and crankshaft must be free of oil.

- Replace the center screw with a new one.

- There must be no traces of oil on the thread and bearing surface.

- Tighten new central screw to 90 Nm, then tighten 1/4 turn (90°) (turning can be done in several stages).

Further installation is carried out in the reverse order of removal.

Attention!

- Before removing the crankshaft, it is necessary to provide a place for placing the parts to be removed so that the driving rotor is not damaged.

- To carry out installation work, the engine must be installed on an assembly stand for engines and transmission units.

Visitor comments