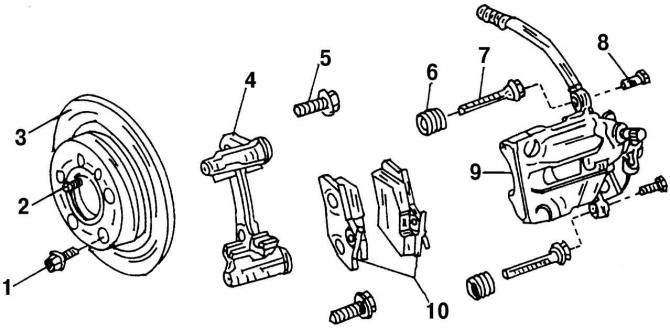

Pic. 324. Details of the rear wheel brake mechanism: 1 - wheel bolt, 140 Nm; 2 - bolt, 10 Nm; 3 - brake disc; 4 - bracket (shoe guide); 5 - bolt, 110 Nm; 6 - rubber cuff; 7 - guide pin; 8 - bolt, 35 Nm; 9 - brake cylinder assembly with caliper; 10 - brake pads

The design of the rear wheel brake mechanism is shown in (pic. 324).

Disassembly brake mechanism in the following order:

- put the back of the car on a support and remove the rear wheels;

- release the parking brake. Disconnect the parking brake cable from the brake caliper;

- remove the brake pads;

- if necessary, remove the brake hose from the wheel cylinder;

- clamp the cylinder assembly with the caliper in a vise. Unscrew the parking brake cable holder;

- using a special key VW3272, unscrew the piston from the brake cylinder;

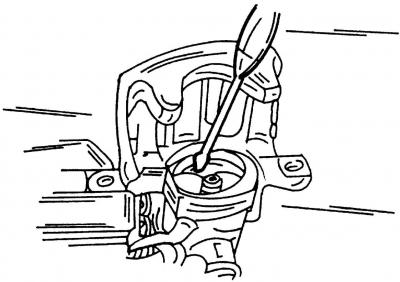

Pic. 325. Removing the sealing ring of the brake cylinder

- carefully with a screwdriver (pic. 325) Remove the O-ring from the brake cylinder housing. Be careful not to damage the cylinder bore;

- thoroughly clean and check the condition of all parts of the brake mechanism. If the cylinder and piston are in good condition, use a repair kit when reassembling. It is recommended to replace the cylinder O-ring and dust ring with new ones. Be sure to check that the repair kit matches the year of manufacture.

Assembly brake mechanism of the rear wheel, carry out in the reverse order of disassembly, while:

- install a new sealing ring in the cylinder groove, having previously lubricated it with brake fluid;

- apply graphite grease or grease «ditor» on the surface of the piston;

- put the dustproof ring with the outer working edge on the piston and insert the piston into the cylinder bore;

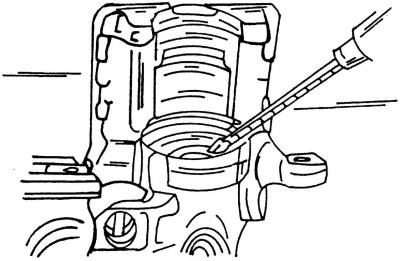

Pic. 326. Installing the dust ring in the groove of the brake cylinder

- using a screwdriver, carefully press the inner working edge of the dust ring into the groove of the cylinder (pic. 326);

- using a special key VW3272 or a steel strip, screw the piston into the brake cylinder. While screwing in, evenly press on the piston. In this case, the outer working edge of the dustproof ring will enter the piston groove as soon as it is opposite it;

- apply grease to the brake actuator bleeder and tighten it;

- bleed the air from the brake cylinder. To do this, put a hose on the bleeder fitting, and put its end on a syringe filled with brake fluid. Fill the cylinder with brake fluid until it comes out through the brake hose connection;

- after assembling and installing the brake mechanism, restore the fluid level in the tank and bleed the hydraulic drive system.

Visitor comments