Only brakes from ATE should be installed on the car (Teves) and brake pads of brands recommended by the manufacturer of the car.

Attention! Brake pads should only be changed as a set. In no case do not rearrange the pads from the outside of the brake disc to the inside and vice versa in order to equalize possible wear. Install only parts recommended «Volkswagen».

If you plan to install old brake pads, then mark with paint before removing them (marker, core) the relative position of the brake pads in relation to the calipers, so that during installation they do not confuse the inner and outer brake pads and the wheel on which they were installed. Withdrawal front brake pads in the following order:

- loosen the front wheel bolts slightly;

- mark with paint (marker) mutual arrangement of wheels, brake discs and wheel hubs;

- raise the front of the car, put it on a support, unscrew the mounting bolts and remove the front wheels;

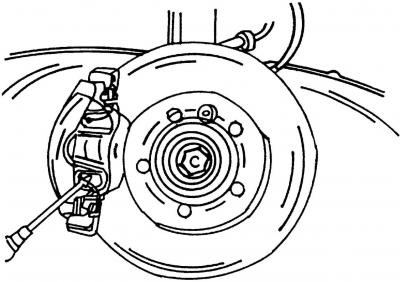

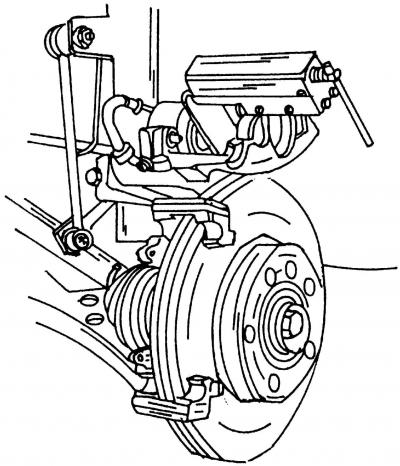

Pic. 312. Removing the spring clamp from the disc wheel brake caliper

- insert a screwdriver into the spring clip (pic. 312) and remove it from its mounting in the brake caliper housing;

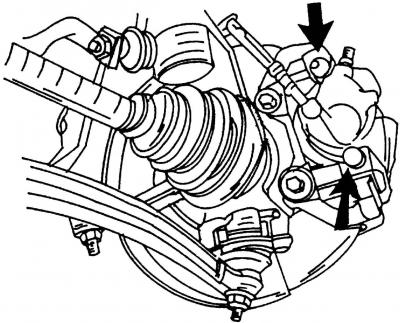

Pic. 313. Locations of the protective caps of the guide pins (shown by arrows)

- use a narrow screwdriver to remove the protective caps (pic. 313) guide fingers;

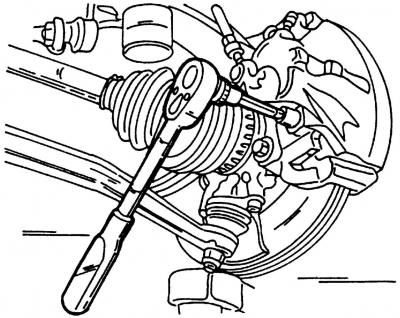

Pic. 314. Unscrewing the lower and upper guide pins (do not remove the caliper bolts)

- unscrew the lower and upper guide pins from the caliper with a hex wrench (pic. 314) and take them out;

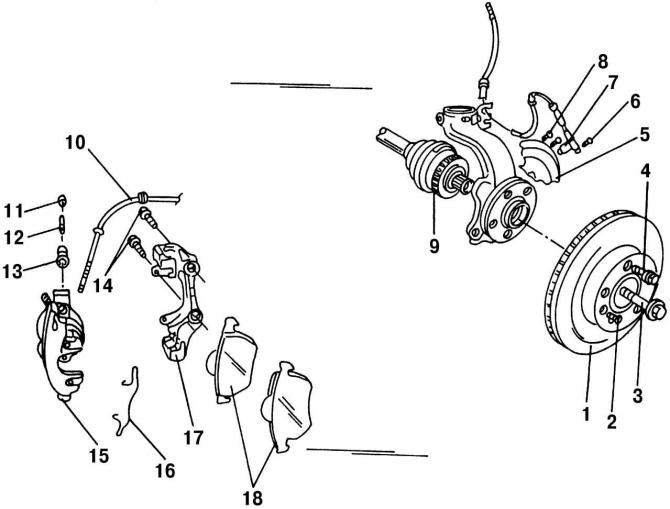

Pic. 315. Front wheel brake: 1 - brake disc, 25 mm thick; 2 - a bolt with an internal hexagon, 10 Nm; 3 - drive shaft bolt, 200 Nm; 4 - wheel bolt, 140 Nm; 5 - protective cover; 6 - bolt, 10 Nm; 7 - sensor system ABS, which determines the speed of the wheel; 8 - bolt, 10 Nm; 9 - toothed rim of the speed sensor; 10 - brake hose; 11 - protective cap; 12 - guide pin, 25 Nm; 13 - sliding sleeve; 14 - bolts, 200 Nm; 15 - brake cylinder assembly with caliper; 16 - spring clamp; 17 - bracket (shoe guide); 18 - brake pads

- lift the brake caliper by moving it up and back and tie it to the body with a wire shackle. Brake hose 10 (pic. 315) do not disconnect, it should not be twisted, bent and be stretched;

- disconnect the inner brake shoe from the brake piston and remove it together with the clamping bracket;

- Remove the outer brake pad from the brake caliper. If it is stuck, then carefully separate it with a screwdriver.

Attention! It is forbidden to press the brake pedal with the brake pads removed, as this will lead to the piston falling out of the brake cylinder, leakage of brake fluid and depressurization of the system.

Check check the technical condition of the brake mechanism before installing the front pads in the following order:

- clean all parts and carefully check their condition;

- check the condition of the surface of the piston and cylinder. If they are worn, damaged, or severely corroded, replace the cylinder and piston. Remove corrosion from the cylinder body with a wire brush;

- thoroughly clean the guide surfaces and the places where the pads are installed in the housing opening with a soft metal brush and wipe with a rag soaked in alcohol (gasoline cannot be used). Do not use oily solutions or sharp instruments;

Warning! Carry out all work on cleaning the brake mechanisms in respiratory protection equipment - respirators, since the dust from the brake pads released as a result of the functioning of the brake mechanisms is harmful to health.

- check that the protective caps of the guide pins fit well in the holes of the disc brake caliper. Replace hardened, torn protective caps;

- check the cleanliness of the working surfaces of the brake discs with your fingers. Remove oil and dirt from them. On its surface, scoring, warping, deep risks, as well as other damages that increase wear of the linings or reduce braking efficiency are not allowed. It is allowed to grind or groove the disc simultaneously from both sides, but both sides must be processed to the same depth, and the thickness of the disc should not be less than acceptable;

Attention! Brake discs with corroded brake surfaces must be replaced.

- measure the actual thickness of the brake discs and brake pads. Brake discs with a blue or gray coating should be cleaned before installing new pads;

- check for cracks on the dust cap of the brake cylinder piston. Replace a damaged dust cap immediately, as penetrating dust quickly causes brake fluid to leak.

Installation front brake pads in the following order:

- remove the protective adhesive film from the bearing surface of the outer brake pad and carefully install the pad into the caliper;

Pic. 316. Installing the piston in the brake cylinder with a clamp

- with a vice (pic. 316) or wooden (plastic) without distortions, move the piston inside the brake cylinder. Be careful not to damage the piston surface and dust cap. When the piston is pressed in, the level of brake fluid in the compensation tank rises, therefore, before sinking the piston, pump out part of the fluid from the tank with a siphon-pear to prevent it from splashing out of the tank;

- Check with a helper that the piston can move freely. To do this, install a wooden block in the caliper, slowly press and release the brake pedal. The piston of the brake cylinder should easily come out and come back in (while the rest of the brake mechanisms must be in working condition);

- clamp the inner brake shoe into the piston of the cylinder;

- install the outer brake pad into the caliper, lining to the brake disc. The pads must be clean and fit exactly into the guides;

Note. When installing the brake pads, be careful not to damage the adhesive on the metal plate.

- carefully install the brake caliper on the brake disc, in its working position, insert clean guide pins, wrap and alternately tighten them with a torque of 25 Nm;

- put protective caps on the heads of the guide pins;

- Install the brake pad spring onto the caliper. If installed incorrectly, the automatic supply of the external brake pad does not work;

- press the brake pedal hard several times until you feel a strong resistance. In this case, the brake pads will take their working position and ensure a good fit to the brake disc;

- bleed the brake system, if necessary;

- install and temporarily secure (by hand) wheel bolts;

- lower the car and tighten the wheel bolts crosswise;

- check connections for tightness. Liquid leakage is not allowed;

- check the brake fluid level in the compensation tank and restore it to the required level;

- check the tightness of the brake system with the engine running. To do this, press the brake pedal several times and hold it for a few seconds. The pedal should not sag.

Attention! In the process of running in new brake pads, abrupt and prolonged braking to a complete stop is not recommended.

Visitor comments