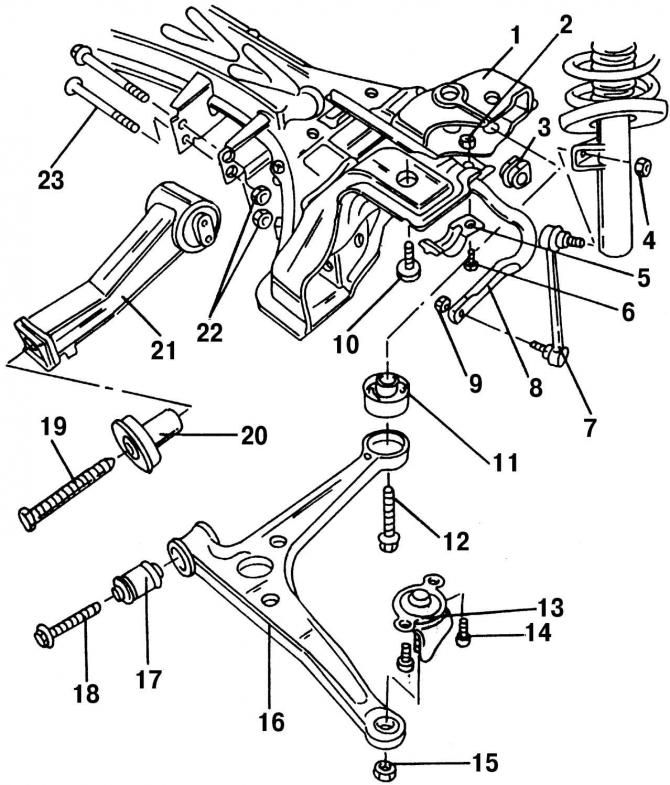

Pic. 291. Fastening the transverse arm, anti-roll bar and pendulum support on the subframe: 1 - subframe; 2 - nut, 55 Nm; 3 - rubber support; 4 - self-locking nut, 100 Nm (replace always); 5 - mounting bracket; 6 - bolt; 7 - connecting rod; 8 - anti-roll bar; 9 - self-locking nut, 100 Nm (replace always); 10 - bolt M14x1.5, 65 mm long, 150 Nm + 90°; 11 - rear bearing of the transverse arm; 12 - bolt M14x1.5, 95 mm long, 150 Nm + 90° (replace always); 13 - ball bearing; 14 - bolt, 55 Nm; 15 - self-locking nut, 55 Nm (replace always); 16 - transverse lever; 17 - transverse arm bearing; 18 - bolt, 90 Nm + 90°; 19 - bolt, 100 Nm; 20 - rubber support; 21 - pendulum support; 22 - nut, 100 Nm; 23 - bolt

Figure 291 shows the elements of the front suspension. The procedure for dismantling the transverse levers of the front suspension:

- place the front of the car on supports and remove the front wheel;

- remove the engine protection;

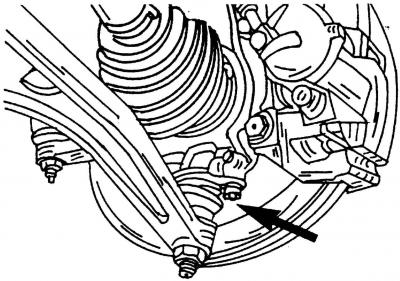

Pic. 284. Two bolts (shown by arrow) hold the bottom of the ball joint to the bottom of the steering knuckle

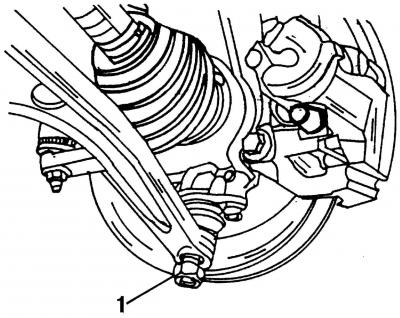

Pic. 292. Before removing the ball joint pin (pic. 285), remove nut 1 to the end of the thread

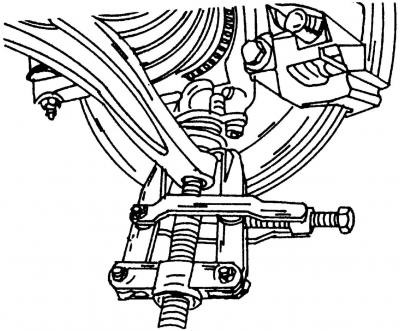

Pic. 285. Remove the pin of the ball joint from the transverse lever using a puller

- unscrew the nut (pic. 292). If you are changing only the ball joint, then unscrew the bolts (pic. 284) and remove the ball joint from the transverse arm (pic. 285);

- unscrew the transverse arm mounting bolts on the inside of the subframe and remove the transverse arm. Remove the transverse arm bushings using a suitable mandrel.

Installation is carried out in the reverse order of the removal process, while:

- use new transverse arm mounting bolts. Since the transverse arm is attached by means of rubber-metal bushings, tighten its bolts only when the vehicle is standing with its wheels on the ground;

- tighten the ball joint mounting bolts to 55 Nm;

- if you removed the ball joint pin from the steering knuckle, then reinstall it until it stops and screw in a new nut. Tightening torque of the nut is 30 Nm, and then tighten it another 90°. If the ball joint pin rotates, then install a 7 mm hex key into it and tighten the nut.

Visitor comments