Attention! A bad tool can damage nuts, bolts, etc. Never allow it. Remember that buying a good tool is the best prerequisite for successful self-maintenance and repair of your car.

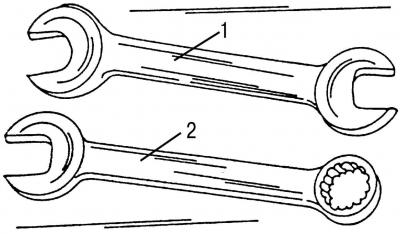

Pic. 4.Tool: 1 - double open-end wrench; 2 - combined wrench with open-end and box heads

A good high-quality tool lasts a long time and in any case justifies the cost of acquiring it. The basis of the tool kit is a set of open-end wrenches 1 (pic. 4).

It is advisable to have a set of wrenches with a socket head, which are very convenient when unscrewing «stuck» screws and nuts, as well as where there is not enough space.

To save costs, you can get by with a set of 2 combination wrenches (pic. 4), which on the one hand have a carob head, and on the other a cap head. It is also advisable to purchase a set of socket heads, which will be very convenient to unscrew hard-to-reach or deeply recessed nuts and screws.

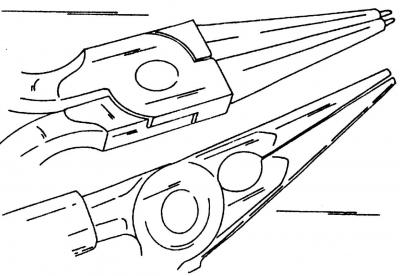

Pic. 5. Round nose pliers (up) and needle nose pliers (at the bottom)

Required are a set of Phillips screwdrivers, pliers and a hammer. In the automotive industry, screws with a so-called socket head are increasingly used «Torx». To unscrew such screws, a special set of heads is used, which are similar to conventional ones, but have a different size (are denoted by the letter «T», For example, «T40» or «T50»). In addition to the basic equipment, you can purchase several more special tools that often turn out to be indispensable, for example, an impact screwdriver, without which it will hardly be possible to unscrew machine-tightened screws with a conventional Phillips screwdriver without damaging them. An impact screwdriver can also be used when tightening screws; round nose pliers are often needed (pic. 5), used when removing safety retaining rings, which are very difficult to remove with a screwdriver.

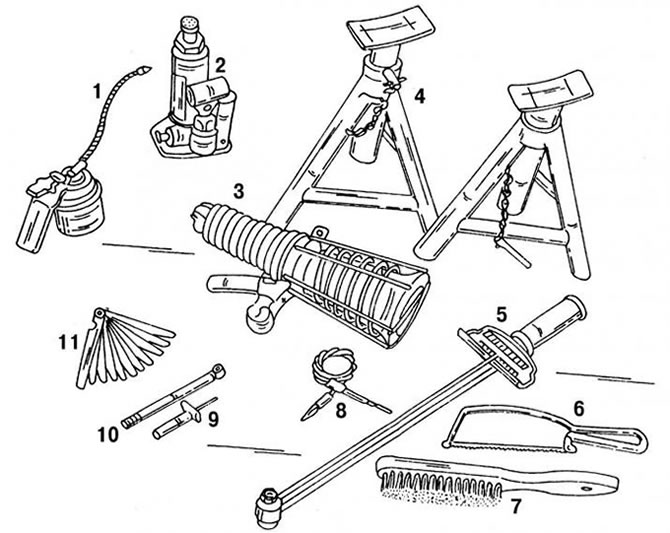

Pic. 6. Recommended tool and accessories: 1 - oiler; 2 - hydraulic jack; 3 - electric portable lamp; 4 - dummy supports; 5 - torque wrench; 6 - a small hacksaw; 7 - wire brush; 8 - control lamp (12 V); 9 - tire profile depth gauge; 10 - pressure gauge for measuring tire pressure; 11 - a set of measuring probes

There are two types of round nose pliers, one for removing external circlips and another type for removing internal circlips. They come with straight or beveled grips. One of the most useful special tools is the torque wrench 5 (pic. 6), which is a regular wrench, adjusted so that it will slip if the set screw or nut tightening torque is exceeded. Such a key may have an arrow that indicates the amount of torque.

The more modern the car model, the more difficult it is to carry out independent repair work. This often requires expensive special equipment used for diagnostics and repairs. So in some cases it is better to simply entrust the repair to a specialist at a car service station (ONE HUNDRED).

Although this repair manual explains how to install various units and mechanisms without the use of special tools, we still strongly recommend that you purchase the most commonly used tools. Some of the most common tools and accessories that are constantly required for self-repair and maintenance of a car are shown in fig. 6.

Safety Requirements and Warnings

When carrying out maintenance and repair work on the car, the following recommendations must be observed to avoid injury and damage:

- free the workplace from unnecessary items to reduce the likelihood that you will trip over something;

- before starting work, check the serviceability of tools and fixtures, put your work clothes in order: button up, tuck in your clothes so that there are no hanging ends, tuck your hair under a tight-fitting headdress;

- when carrying out any type of work, the car must be reliably braked;

- do not work under a vehicle that is only on a portable jack, always substitute additional supports;

- do not carry out maintenance and repair of the car with the engine running, with the exception of certain types of work, the technology of which requires starting the engine;

- keep hands, parts of clothing, tools away from working drive belts, pulleys, etc.;

- never tighten wheels or nuts when the car is raised;

- never open the expansion tank cap on a hot engine. If necessary, put a thick rag around the cap of the expansion tank and slightly unscrew the cap so that steam escapes;

- observe fire safety rules;

- do not operate the engine in an enclosed area that does not have good ventilation to avoid carbon monoxide poisoning;

- never drain engine oil on a hot engine;

- used oils and special liquids are subject to collection and delivery for processing or disposal;

- do not allow brake fluid or antifreeze to get on the car's paintwork;

- as a result of the functioning of the brake mechanisms, dust from the brake linings is released, which is harmful to health. Carry out all work on cleaning the brake mechanisms in respiratory protection equipment - respirators;

- always remove oil or grease residues from the ground so as not to slip on them;

- in case of injury, always cover open wounds with a plaster, try to prevent dirt, oil, etc. from getting on them;

- remove or install heavy units and assemblies together with an assistant;

- do not allow the presence of children or pets near the car during repair work;

- when repairing the exhaust system, wait until it cools down;

- Be sure to wear protective goggles when using power-driven devices such as a drill or grinder. Glasses will not interfere with work under the bottom of the car;

- if possible, try not to work alone under the vehicle;

- never finish the job in a hurry, as you can forget to tighten or just not completely tighten some nuts.

Visitor comments