- always turn off the ignition before disconnecting or connecting the wires of the injection system or the preheater;

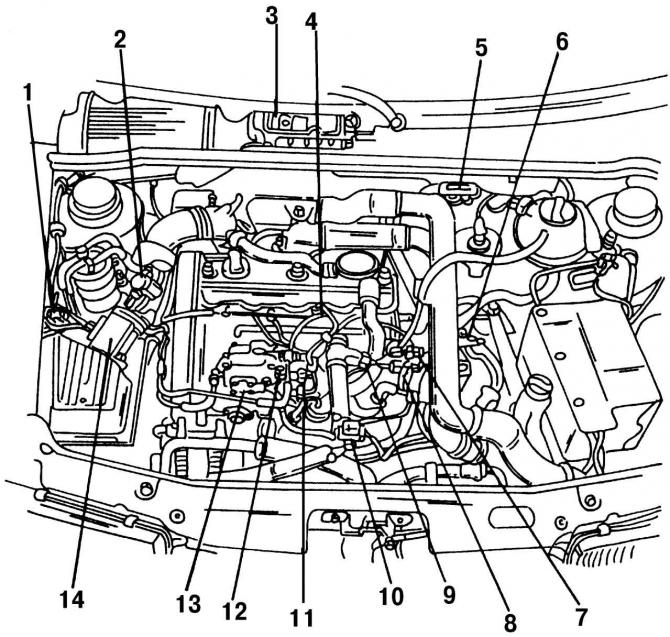

Pic. 470. Elements of the engine power system in the engine compartment: 1 - solenoid valve for enriching the fuel mixture during boost; 2 - EGR valve; 3 - electronic unit of the engine control system; 4 - nozzle with needle lift sensor; 5 - relay of an additional heating element; 6 - intake manifold temperature sensor; 7 - plug block of the needle lift sensor; 8 - plug block of the engine speed sensor; 9 - coolant temperature sensor; 10 - plug-in block of the dispenser temperature sensor; 11 - plug block of the fuel supply shut-off valve and injection start valve; 12 - shut-off valve for fuel supply; 13 - injection pump dispenser; 14 - mass air flow sensor

- sometimes the engine needs to be cranked with a starter (e.g. when checking compression). To prevent the engine from starting, disconnect the plug connector of the fuel shut-off valve 12 (pic. 470);

- disconnect the AB wires only when the ignition is off, so as not to damage the system;

- most of those shown in Fig. 470 elements are electronic or electrical and should be handled with extreme care.

General Precautions:

- All work on the injection system may only be carried out under the strictest conditions of cleanliness. Outdoors, repair work on the injection system should only be carried out when there is no wind to prevent dust from entering the injection system.

- before dismantling, thoroughly clean all parts and assemblies from dust;

- put the removed parts on a clean surface and cover them with paper or polyethylene. Do not use fluffy fabrics for this;

- separate and remove the dismantled parts that will not be installed back;

- check the cleanliness of all installed parts;

- do not use compressed air to purge other parts if the fuel system connections are open;

- do not move the car if any elements of the fuel system are removed;

- Do not allow diesel fuel to enter the cooling system hoses. Clean the hoses immediately if this occurs. Replace hoses contaminated with diesel fuel and thus damaged. The injection pump is not repairable. Replace the faulty high-pressure fuel pump or have it repaired at a service station.

To adjust the injection time of the injection pump, as well as to remove and install it, you must have a special tool. Adjustment of the injection pump can only be carried out at a service station using special equipment.

Visitor comments