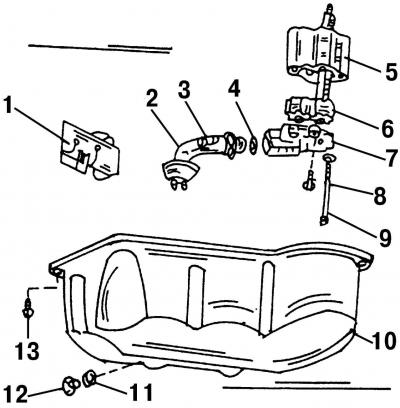

Pic. 452. View of the oil sump and disassembled oil pump: 1 - guide plate; 2 - oil receiving pipe; 3 - a bolt of an oil receiving pipe, 10 Nm; 4 - sealing ring, 10 Nm; 5 - oil pump housing; 6 - gears of the oil pump; 7 - cover of oil pumps with a pressure reducing valve; 8 - short cover bolt, 10 Nm; 9 - long cover bolt, 25 Nm; 10 - oil sump; 11 - sealing ring (always replace with a new one); 12 - drain plug, 30 Nm; 13 - oil sump mounting bolt, 25 Nm

When disassembling the oil pump, refer to Fig. 452.

Remove the two short bolts from the pump cover.

Remove the cover together with the oil pickup pipe.

Remove the gear wheel with the shaft and the gear wheel without the shaft from the pump housing. You can also pull out the drive shaft.

Unscrew both bolts of the oil pick-up tube screen from the pump cover and remove the O-ring located in the center of the tube. Thoroughly clean all parts before checking their condition.

Check the oil pump housing for deformation. If the bearing locations are worn, replace the oil pump housing as this will cause a loss of pressure.

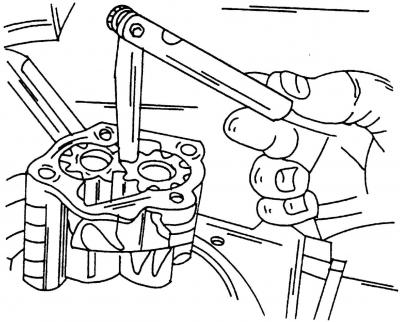

Pic. 454. Measuring the radial clearance in the oil pump

Check the gears for wear by inserting a feeler gauge between the teeth (pic. 454) and measure the radial clearance. Permissible gap 0.05-0.20 mm. If the gap exceeds the allowable, then replace the gears, and if necessary, the entire pump.

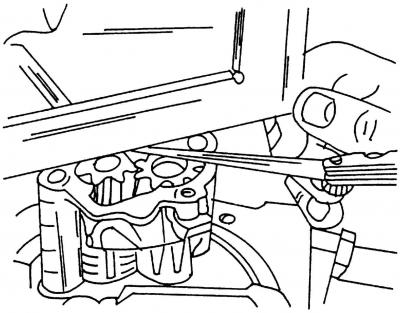

Pic. 455. Measuring the axial clearance in the oil pump

- using a feeler gauge and a steel ruler or angle, measure the axial clearance in the oil pump (pic. 455). The permissible value of the axial clearance is 0.06-0.15 mm.

Check that the drive gear shaft is firmly seated in the pump housing. If it dangles, then replace the pump housing.

If you find damage or wear on the teeth, then replace the gears in pairs. As a rule, wear marks on the side surface of the teeth look like a polished shiny surface.

When assembling the oil pump, make sure that the surfaces of the pump are absolutely clean. Lubricate all parts with oil before assembly. Pay special attention to the lubrication of the gears so that they do not get scuffed and damaged when the engine is first started. Before installing the pump, make sure that the gears turn easily without binding.

When starting the engine for the first time, do not immediately operate it at high speeds so that the oil pump runs in well.

Visitor comments