When removing pushers, the following instructions must be observed:

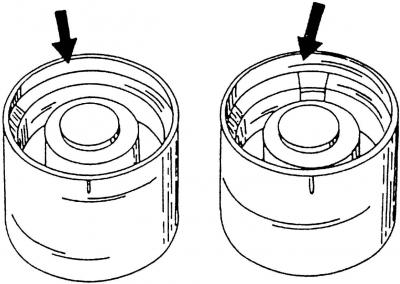

Pic. 412. Marking pushers. Hydraulic tappets can only be tagged from the inside

- immediately after removal, mark the pushers. It is best to mark them with the help of marks applied on the inside. To do this, draw one line on the first pusher, two lines on the second pusher, etc. On fig. 412 shows how the pushers should look after marking them;

- after removing the hydraulic tappets, do not install them with the contact surface down;

- replace the pusher completely, as it cannot be adjusted or repaired.

If the noise of the valves seems too loud to you, then the pushers can be checked as follows:

- start the engine and let it run until the fan turns on;

- increase the engine speed to 2500 min–1 and let it run for about 2 minutes;

- if the tappets are still noisy, then the faulty tappet can be identified by removing the cylinder head cover, as described when disassembling the engine, and rotating the camshaft so that the camshaft cam for the tappet being checked is facing up;

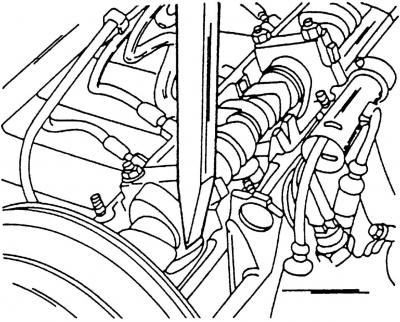

Pic. 413. Checking the operation of hydraulic pushers

- push the pusher down with a piece of plastic or wood (pic. 413). If the gap is more than 0.1 mm before the valve opens, then this pushrod must be replaced.

Attention! After installing a new tappet, do not start the engine after assembly for about 30 minutes, otherwise the engine may be seriously damaged.

Visitor comments