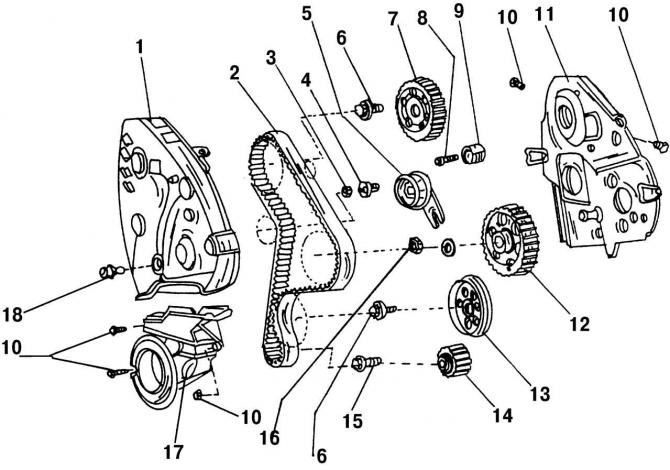

Pic. 414. Elements of the drive mechanism located on the front side of the engine: 1 - upper protection of the toothed belt; 2 - toothed belt; 3 - nut, 20 Nm; 4 - tension roller eccentric; 5 - belt tensioner; 6 - bolt, 45 Nm; 7 - camshaft gear; 8 - bolt, 25 Nm; 9 - roller; 10 - bolt, 10 Nm; 11 - rear drive belt protection; 12 - gear wheel of the high pressure fuel pump; 13 - intermediate shaft pulley; 14 - crankshaft gear; 15 - bolt, 90 Nm + 90°; 16 - nut, 55 Nm; 17 - lower protection of the toothed belt; 18 - spacer spring clamp

Details of a drive of the gas-distributing mechanism are shown in fig. 414. In order to get to the parts of the timing mechanism drive, you need to remove the V-belt of the power steering pump and the V-ribbed belt of the generator drive. The work is described in the relevant section.

The camshaft is driven by a toothed belt that runs through pulleys located on the camshaft, crankshaft and injection pump. The intermediate shaft is driven by a pulley without gearing.

Once again, we draw your attention to the fact that when working with the gas distribution mechanism, it is necessary to have a special tool, for example, to adjust the high-pressure pump drive and camshaft, without which adjustment should not be made. Since the operation of the valves depends on the correct adjustment of the camshaft drive, incorrect adjustment of the camshaft drive can be very costly. Always be aware that a belt can jump one tooth and this can cause serious engine damage as the valves will open and close at the wrong moment, causing serious damage to the pistons. For this reason, the toothed belt should be changed every 100,000 km, as a broken drive belt can cause similar damage.

A special tool is also required to adjust the timing belt tension. If necessary, you can also adjust the belt tension by eye, but we recommend that you check the belt tension at the workshop as soon as possible after such an adjustment. Checking the belt tension does not take much time.

The following work should only be carried out if you have the appropriate special tool at your disposal. Otherwise, you should contact the service station.

Provided that the belt is not damaged, it has a service life of up to 100,000 km.

The belt tension is adjusted by the installed tension roller with an adjusting eccentric.

Visitor comments