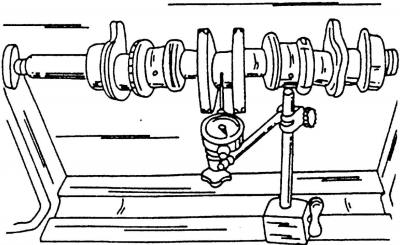

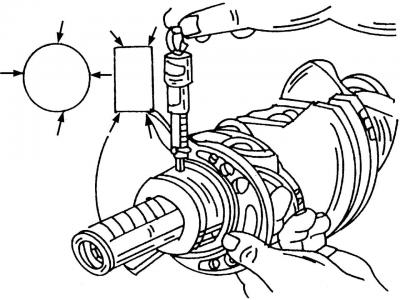

Pic. 442. Measurement of the beating of the crankshaft

Clamp the crankshaft in a lathe (pic. 442) or clamp both shaft journals into wedges and use an indicator to measure the runout on the middle journal. The runout should not be more than 0.06 mm. Otherwise, the shaft must be replaced. Currently, there is no way to straighten the crankshaft.

Measure the runout of the main bearings and connecting rod bearings if the vehicle with this shaft already has high mileage. In a car service, this is used «Plastigage» - plastic wire, however, as experience shows, it can be quite difficult to obtain. If you are unable to purchase one «measuring wire», then the same operation can be done in another way, which is described below. If you are measuring with «Plastigage», then proceed as follows:

- clean the bearing shells thoroughly and place them in the cylinder block bearing bed or in the connecting rods. well paste «noses» bearing shells in guides;

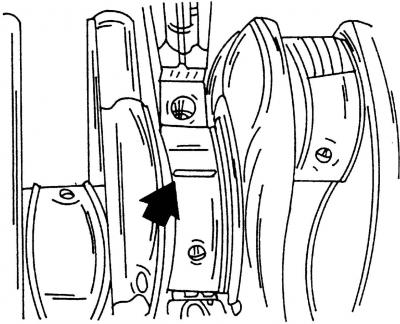

Pic. 443. Put a piece of wire «Plastigage» in the direction shown on the bearing journals

- put in a piece «Plastigage» on the neck of each main bearing (pic. 443, shown by arrow) and install the main bearing cap with the bearing shells inserted. Tighten the bolts with a tightening torque of 65 Nm. After that, do not rotate the shaft any more;

- To check the clearances of the connecting rod bearings, place the connecting rod on the crankshaft crankpin, and lay «Plastigage» on top of the crankshaft journal. Install bearing cap with bushing (pay attention to the correct position again «guide noses») and tighten the nuts with a tightening torque of 30 Nm. Since the shaft can no longer be rotated, measurements are taken on two connecting rod bearings located at BDC;

- unscrew the caps on the main bearings; on connecting rod bearings, unscrew both covers in turn;

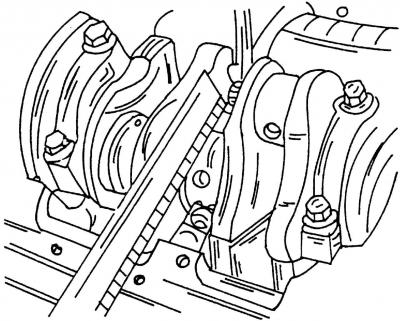

Pic. 444. Measurement of flattened wires «Plastigage» using a measuring line

- using the measuring ruler included in the kit «Plastigage», measure the crushed strips of material at the widest point by placing a ruler on the plastic strips (pic. 444). If this value exceeds 0.17 mm for main bearings or 0.12 mm for connecting rod bearings, then new bearing shells should be installed, taking into account whether or not the journals have been ground before.

If you don't have plastic wire «Plastigage», and you yourself have some experience in such measurements, then the runout of the main and connecting rod bearings can be measured in the manner described below, which will allow you to draw the appropriate conclusions.

Install the bearing caps together with the enclosed bearing shells in the cylinder block, and tighten the bolts to 65 Nm. Make sure the earbuds are installed in their original locations. If connecting rod bearings are being measured, insert the shells into the connecting rods and connecting rod caps and tighten the caps with the old nuts to 30 Nm.

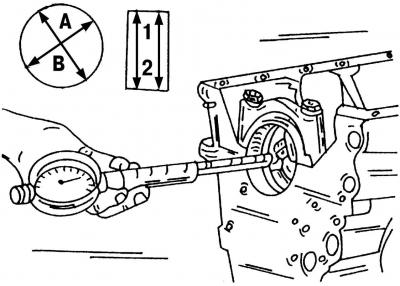

Pic. 445. Measuring the diameter of inserted bearing shells using an indicator. Measurements are taken in direction A and B, as well as in direction 1 and 2

Measure the bearings in turn - the measurement scheme in fig. 445. Pay particular attention to the direction of measurements A and B, as well as measurement points 1 and 2. Record the measurement results for each individual bearing.

Pic. 446. Measurement of the diameter of the journals of the main bearing. Take measurements in the places indicated by the arrows. Connecting rod journals can be measured in the same way

Measure the diameter of all bearing journals one by one with a micrometer. At the same time, pay attention again to the measurement sites, which are indicated in Fig. 446 arrows. Record the measurements for each bearing journal.

Subtract the bearing diameter measurements from the inside diameter of the bearing bores. As a result, you will get the runout of the main and connecting rod bearings, the value of which should correspond to the values specified above.

In order to check the runout of the connecting rod bearings, turn the crankshaft and measure the next two connecting rod journals as described.

Visitor comments