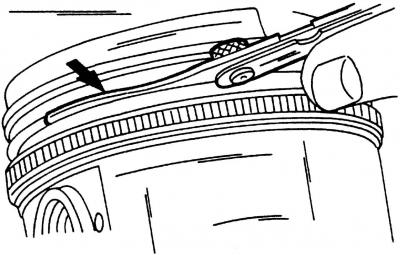

Pic. 427. Checking clearance between piston rings and grooves

Measure the height clearance between the piston rings and grooves using a feeler gauge (pic. 427). If the compression ring gap is greater than 0.25 mm, or the oil scraper ring gap is greater than 0.15 mm, then either the rings or the piston are worn. The nominal values are given in the table of tolerances and control.

Insert all piston rings one by one, starting from the bottom relative to the crankcase, into the cylinder bore. Turning one of the pistons upside down, push the rings down about 20 mm. After that, they will be directly in the cylinder bore.

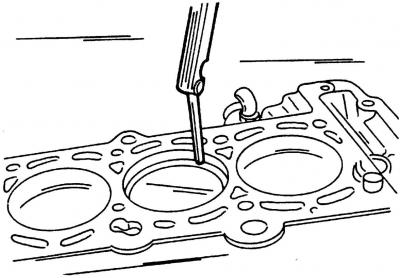

Pic. 428. Checking the gap in the lock of the rings. Insert the piston rings with the upside down piston into the cylinder bore so that they are horizontal in the cylinder bore

Insert a feeler gauge into the gap between the two ends of the ring to measure the gap in the piston ring lock. On fig. 428 shows how to correctly measure the clearance. For compression piston rings, the clearance should be 0.2-0.4 mm; for oil scraper rings - 0.25-0.4 mm. The wear limit of all rings is 1.0 mm.

With a slight gap (e.g. on new rings, which should also be measured) the ends of the rings can be filed off. To do this, hold the file in a vise and grind the ends of the rings on it. If the thermal gap is too large, the corresponding ring must be replaced.

Check piston pins and connecting rod bushings for wear and tear. Also, if only one connecting rod is damaged, then the entire assembly should be replaced. Always replace connecting rod bearing bolts with new ones. Check the connecting rods with a connecting rod straightener for deformation and twisting. The values obtained should be minimal. If you have any doubts about the condition of the connecting rods, then contact the service station in order to carry out the appropriate measurements there. If one connecting rod is bent, then the whole set must be replaced.

Visitor comments